Description

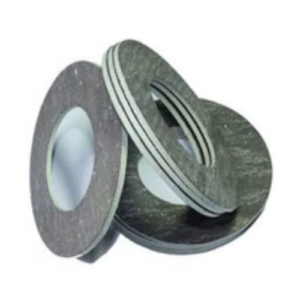

Soft Iron API 6A Octagonal Ring Joint Gasket

| Stainless Steel | Seals Ring | Api | Gasket |

| Wellhead | Ring Joint Gasket |

High Light: API 6A octagonal ring joint gasket, soft iron RTJ joint, API 6A RTJ joint

Our company has been certified by ISO 9001:2008 and SGS standard. we provides superior products and best service to the customers by bringing in advanced

CNC machines, sawing machines, spectrograph, desktop hardness, laser marking machine, coating thickness gauge and other equipments.

We specializes in ring joint gasket, including ring gasket in R, RX, BX, IX types, lens gasket, weld ring gasket and bonnet gasket(according to client’s drawing). The metal gasket designed for use in high pressure, high temperature application necessitated the need for a high integrity seal. Our products are widely used in flat gate valve, Christmas tree, pipeline fittings, flange, high pressure vessel, oil &gas industry, wellhead assembly, petrochemical industry and the like.

We can offer more than 30 kinds of materials, such as 321SS, 347SS, 316SS, 304SS, Inconel 625, Monel 400, INCOLY 825, Nickel 200, Duplex F44, soft iron, low carbon steel and so on. We could produce the maximum outside diameter is 2500mm.

We supply high quality Ring joint Gaskets for high pressure and temperature service conditions. These gaskets are widely used in Refineries, Petrochemical Industries, Oil drilling well head equipments, Pressure Vessels, valves, Christmas Tree valves and Pipe lines. Ring joints Gasket are strictly manufactured as per API-6A and ASME B16.20 specification.

‘R’ Type

octagonal/oval

–NB1/2″ to 24″ Class Rating 150 to 2500 ASME B16.20

–NB26″ to 36″ Class 300 to 900 ASME B16.20 Series A

–NB1/2″ to 20″ Class API 6A

R Oval & Octagonal gasket ring Can be used on standard flat bottomed groove flanges and older round bottomed groove flanges

R Oval & Octagonal gasket ring Can be used for ASME B16.5 flange class 150 to 2500 and

API 6B to Class 5000

»Soft iron and carbon steel gaskets are zinc plated to prevent

corrosion

» All rings are marked with the ring number, material and the

date of manufacture and API designation.

we supplies ring joint gaskets (RTJ Gasket) with the hardness numbers as follows:

|

GASKET MATERIALS |

BRINELL HARDNESS NUMBER (max) |

ROCKWELL HARDNESS NUMBER (max) |

IDENTIFICATION |

|---|---|---|---|

| Soft iron | 90 | 56 | D |

| Low carbon steel | 120 | 68 | S |

| 4-6% Chrome 1/2% molybdenum | 130 | 72 | F5 |

| 304 Stainless Steel | 160 | 83 | S304 |

| 316 Stainless Steel | 160 | 83 | S316 |

| 347 Stainless Steel | 160 | 83 | S347 |

| Common Materials | |||

| Material | HB Hardness | Temperature Limitations | Identification |

| Soft Iron | 90 | -60 to +400 °C | D |

| Low carbon steel | 120 | -40 to +500°C | S |

| 4%-6% Cr ½% Mo:F5 | 130 | -125 to +500°C | F5 |

| Stainless steel 304/304L | 160 | -250 to +650°C | S304 or 304L |

| Stainless steel 316/316L | 160 | -196 to +800°C | S316 or 316L |

| Stainless steel 321 | 160 | -250 to +870°C | S321 |

| Stainless steel 347 | 160 | -250 to +870°C | S347 |

| Stainless steel 410 | 170 | -20 to +500°C | S410 |

| Inconel 625 | – | 1000°C | 625 |

| Incoloy 825 | – | 1000°C | 825 |

| Hastelloy C-276 | – | 1000°C | C-276 |

| Duplex | – | 800°C | S31803 |

| Titanium | – | 540°C | TI |