Description

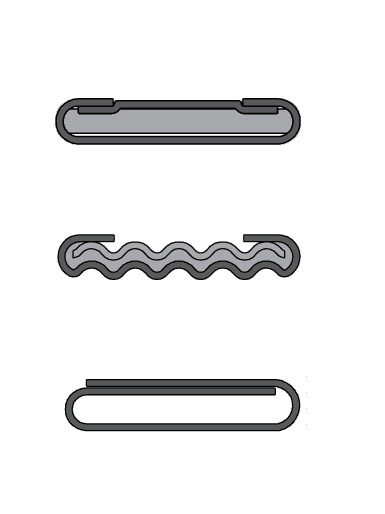

DOUBLE JACKETED GASKET

Double-jacketed gaskets are probably the most commonly used style of gaskets in heat exchanger applications. They are available in virtually any material that is commercially available in 26-gauge sheet. They are also extensively used in standard flanges where the service is not critical. Since most double-jacketed gaskets are custom made, there is virtually no limit to size, shape or configuration in which these gaskets can be made.

DOUBLE JACKETED CORRUGATED GASKET

The double-jacketed corrugated gasket is an improvement on a plain jacketed gasket in that the corrugations on the gasket will provide an additional labyrinth seal. It also provides the advantage of reducing the contact area of the gasket, enhancing its compressive characteristics. A double-jacketed corrugated gasket still relies on the primary seal on the inner lap.

SINGLE-JACKETED OVERLAP

In the single-jacketed overlap construction the maximum flange width is approximately 1/4″. this type of gasket is used when total enclosure of the soft filler material is required and when the flange width makes it impractical to use a double-jacketed gasket.

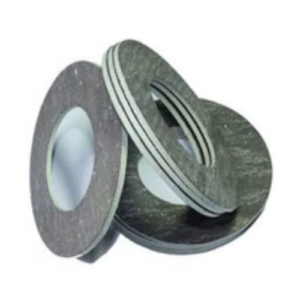

Metal Jacketed Gasket Application

1、Temperature:~450℃

2、Pressure:≤6.4MPa

3、Gasket Factor:m-3.75

4、Gasket Seating:y=60MPa

5. Maxmum Size:~5000mm

| Metal Materials | Germany Standard | HB | Temperature (℃) | Density g/cm3 |

|---|---|---|---|---|

| Carbon Steel | 1.1003/1.0038 | 90~120 | -60~500 | 7.85 |

| SS304/SS304L | 1.4301/1.4306 | 130~180 | -250~550 | 7.9 |

| SS316/SS316L | 1.4401/1.4404 | 130~180 | -250~550 | 7.9 |

| Copper | 2.0090 | 50~80 | -250~400 | 8.9 |

| Aluminum | 3.0255 | 20~30 | -250~300 | 2.73 |

Nonmetal Materials of Metal Jacketed Gaskets

Flexible Graphite

- Compressed Asbestos Fiber

- Ceramic fibre

- Non-Asbestos

- Micarex and etc.

The other materials can be available as the requirement of the buyer.