Octagonal Ring Joint Gasket

LEADING SUPPLIER

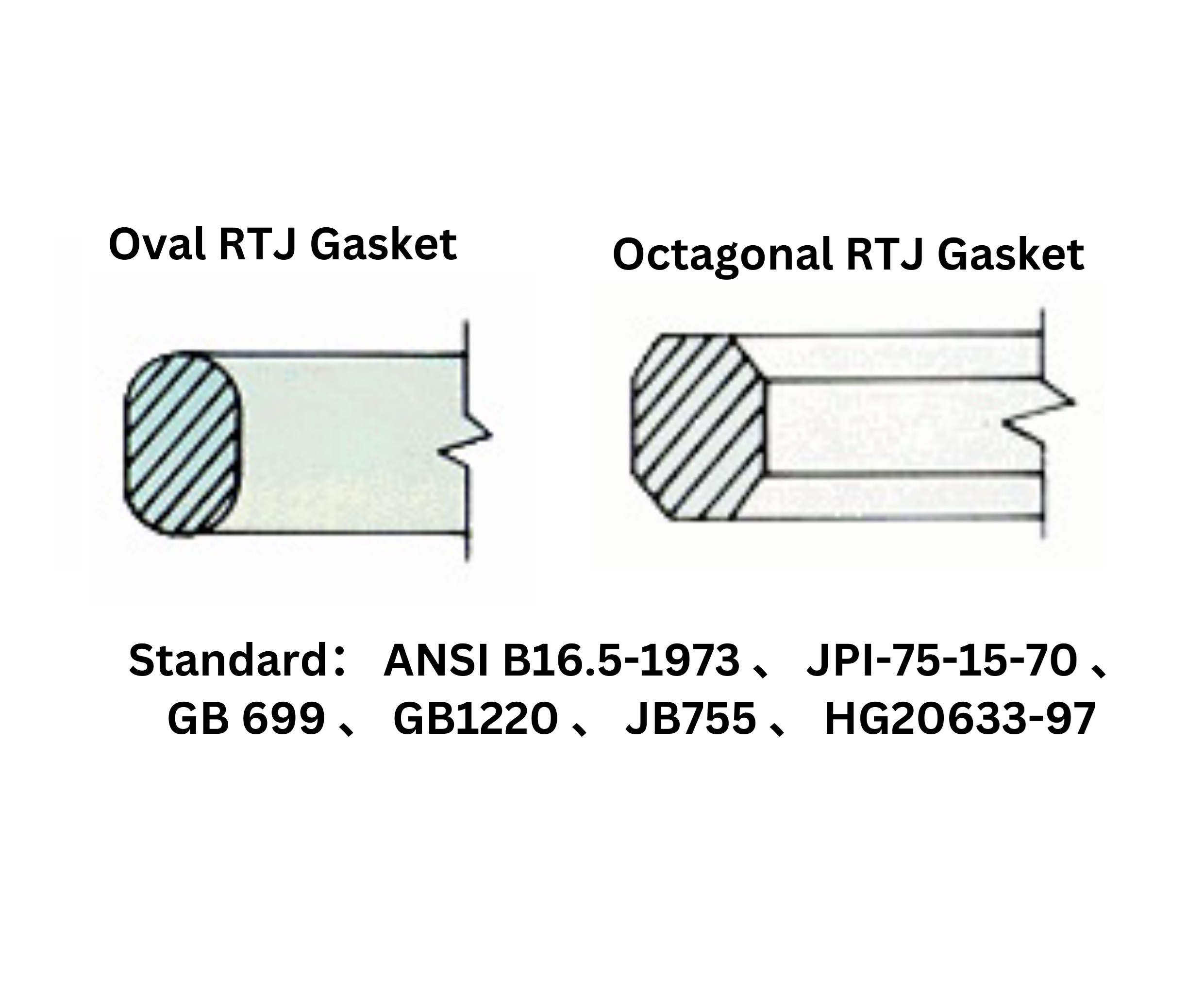

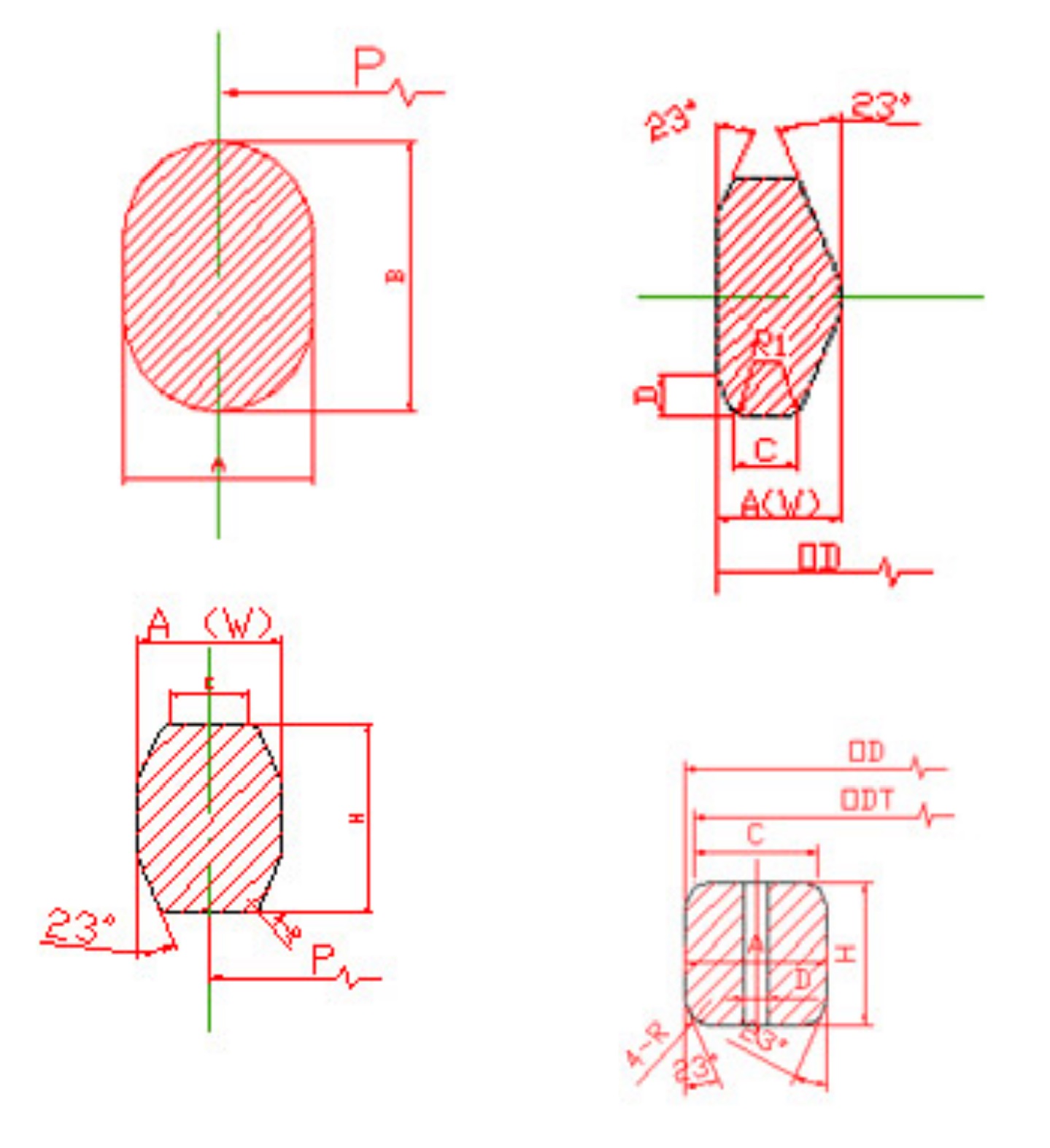

API ring Joint gaskets come in two basic types, an oval cross section and an octagonal cross section. These basic shapes are used in pressures up to 10,000 psi. The dimensions are standardized and require specially grooved flanges. The octagonal cross section has a higher sealing efficiency than the oval and would be the preferred gasket. However, only the oval cross section can be used in the old type round bottom groove. The newer flat bottom groove design will accept either the oval or the octagonal cross section. The sealing surfaces on the ring joint grooves must be smoothly finished to 63 micro inches and to be free of objectionable ridges, tool or chatter marks. They seal by an initial line contact or a edging action as the compressive forces are applied.

The octagonal cross section has a higher sealing efficiency than the oval and would be the preferred gasket. However, only the oval cross section can be used in the old type round bottom groove.

- Materials: soft iron,SS304, SS316, carbon steel , SS321 and the other alloy material

- With high temperature, high pressure and corrosion resistance of the excellent characteristics.

- Mainly used in high temperature and high pressure pipe (steam and oil industry, petroleum chemical industry) tower, tank, heat exchanger, the pipe joints.

- Standard: ANSI B16.5-1973 、 JPI-75-15-70 、 GB 699 、 GB1220 、 JB755 、 HG20633-97