Description

A rubber spring, also known as a rubber suspension spring or elastomeric spring, is a type of mechanical spring made primarily of rubber or elastomer materials. It is designed to provide vibration isolation, shock absorption, and noise reduction in various mechanical and industrial applications. Here’s a detailed overview of this product:

Construction:

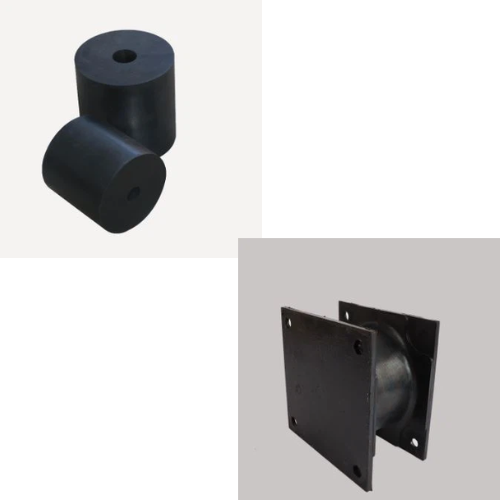

Elastomeric springs are typically constructed using layers of elastomer materials, such as natural rubber, synthetic rubber, or silicone rubber. These materials are chosen for their elasticity, durability, and resistance to wear and tear.

The rubber is often molded into specific shapes, such as cylindrical, conical, or rectangular, depending on the application requirements. Metal inserts or reinforcements may also be added for additional strength and stability.

Functionality:

Elastomeric springs function by flexing and deforming under load, absorbing and dissipating energy to reduce vibration, shock, and noise transmission. They provide a compliant and flexible support system that isolates machinery and equipment from external disturbances.

When subjected to dynamic loads or vibrations, the rubber material undergoes deformation, storing energy temporarily and releasing it gradually. This damping effect helps to smooth out movements, minimize oscillations, and protect sensitive components from damage.

Applications:

Elastomeric springs find widespread use in various industries and applications, including automotive, aerospace, construction, industrial machinery, HVAC systems, and transportation vehicles.

In the automotive industry, elastomeric springs are commonly used in vehicle suspension systems to provide a smoother ride, improve vehicle handling, and reduce road noise and vibrations.

In industrial machinery, elastomeric springs are employed to isolate vibrating equipment, such as compressors, pumps, engines, and generators, from their surroundings, preventing structural damage and minimizing noise pollution.

They are also utilized in building and construction projects to absorb vibrations caused by wind, seismic activity, or machinery, protecting structures and occupants from damage and discomfort.

Reviews

There are no reviews yet.