Description

| Carbon Steel: | Gasket | Stainless Steel: | Seal |

| Metal: | Seals Ring |

High Light: Titanium oval ring joint gasket, R105 ring joint flange, Titanium ring joint flange

We provides superior products and best service to the customers by bringing in advanced CNC machines, sawing machines, spectrograph, desktop hardness, laser marking machine, coating thickness gauge and other equipments.

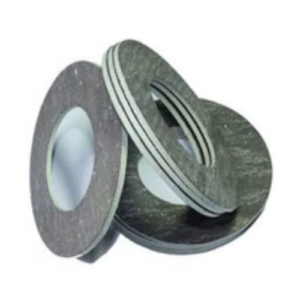

We specializes in ring joint gasket, including ring gasket in R, RX, BX, IX types, lens gasket, weld ring gasket and bonnet gasket(according to client’s drawing). The metal gasket designed for use in high pressure, high temperature application necessitated the need for a high integrity seal. Our products are widely used in flat gate valve, Christmas tree, pipeline fittings, flange, high pressure vessel, oil &gas industry, wellhead assembly, petrochemical industry and the like.

We can offer more than 30 kinds of materials, such as 321SS, 347SS, 316SS, 304SS, Inconel 625, Monel 400, INCOLY 825, Nickel 200, Duplex F44, soft iron, low carbon steel and so on. We have over 10 years experience in export business.

Ring joint gasket is machined from solid metal in a variety of shapes according to API 6A & ASME B16.20 standards,it’s designed for high pressure ,high temperature or highly corrosive applications by selecting the most suitable material and shape. It is designed to with stand exceptionally high assembly loads over a small area, thus producing high seating stresses.Ring type Joint Gaskets are designed to seal by “initial line contact” or wedging action between the mating flange and the gasket. By applying pressure on the seal interface through bolt force, the softer metal of the gasket flows into the imperfections of the harder flange material, creating a very tight and efficient seal.

The contact face is in oval shape. It provides a high reliabililty seal. These gaskets are manufactured in accordance to API 6A of ASME B16.20 to suit API613 and ASME/ANSI B16.5 Flanges. Fits the round and flat bottom ring groove flange

As a result of metal to metal sealing media they are made to be free of indentations, tool marks etc and have a surface finish of maximum,

· R, RX – 63 microinches Ra (1.6 micrometer Ra).

Thus Gasket supplies ring joint gaskets (RTJ Gasket) with the hardness numbers as follows:

|

GASKET MATERIALS |

BRINELL HARDNESS NUMBER (max) |

ROCKWELL HARDNESS NUMBER (max) |

IDENTIFICATION |

|---|---|---|---|

| Soft iron | 90 | 56 | D |

| Low carbon steel | 120 | 68 | S |

| 4-6% Chrome 1/2% molybdenum | 130 | 72 | F5 |

| 304 Stainless Steel | 160 | 83 | S304 |

| 316 Stainless Steel | 160 | 83 | S316 |

| 347 Stainless Steel | 160 | 83 | S347 |

| Material | DIN/EN | AISI/ASTM | Identification | Max. Hardness HB [Brinell] |

| X5CrNiMo17-12-2 | 1.4401 | 316 | S316 | 160 |

| X6CrNiNb18-10 | 1.4550 | 347 | S347 | 160 |

| X6CrNiMoTH 7-12-2 | 1.4571 | 316TÌ | S316TI | 160 |

| X2CrNiMo17-12-2 | 1.4404 | 316L | S316 | 160 |

| 12CrMo195 | 1.7362 | A182 | F5 | 130 |

| Soft iron | 1.1003 | Soft iron | D | 90 |

Marking

The marking is done on the outer surface of each gasket.

Manufacturer name and symbol

Identification number with prefixed letters for the design

Material abbreviations

Manufacturer’s specification