Adhesive Tape Rubber Bonding: A Game-Changer for Rubber Seals and Gaskets

Rubber seals and gaskets play a critical role in industrial and domestic applications, offering durability, flexibility, and airtight sealing solutions. A major innovation enhancing their functionality is adhesive tape rubber bonding, a technique that uses adhesive tape to bond rubber to surfaces, making installation quicker, cleaner, and more efficient.

This blog explores the benefits, applications, and key considerations of adhesive tape rubber bonding, highlighting its transformative potential in the manufacturing and usage of rubber seals and gaskets.

What Is Adhesive Tape Rubber Bonding?

Adhesive tape rubber bonding is a process where pressure-sensitive adhesive (PSA) tapes are applied to rubber components to create a durable bond with other surfaces. These tapes eliminate the need for traditional bonding methods like glue, rivets, or fasteners, providing a seamless and strong adhesion solution.

Rubber materials such as EPDM, silicone, or nitrile are commonly used in adhesive tape bonding because of their flexibility and durability. The adhesive tape acts as a bridge, ensuring the rubber component adheres securely to the desired surface, even under challenging environmental conditions.

Benefits of Adhesive Tape Rubber Bonding

1. Easy Installation

- Adhesive tape bonding simplifies the installation process, reducing the time and effort required.

- It eliminates the need for complex tools or additional materials like liquid adhesives.

2. Clean and Precise Application

- Adhesive tapes ensure a mess-free bonding process, making it ideal for environments that require precision.

3. Strong and Durable Bonding

- High-quality adhesive tapes provide excellent strength and resistance to stress, vibrations, and environmental factors.

4. Cost-Effective

- By reducing the need for extensive labor and tools, adhesive tape bonding proves to be cost-efficient for both manufacturers and end users.

5. Versatility

- Suitable for bonding rubber to a wide variety of surfaces, including metals, plastics, glass, and painted surfaces.

6. Environmental Resistance

- Adhesive tapes used for rubber bonding are designed to withstand extreme temperatures, moisture, UV radiation, and chemicals.

Common Applications of Adhesive Tape Rubber Bonding

1. Automotive Industry

- Used in weatherstripping, noise dampening, and securing seals in doors, windows, and trunk compartments.

2. Construction

- Facilitates the installation of seals in windows, doors, and HVAC systems for improved insulation and energy efficiency.

3. Electronics

- Provides reliable bonding solutions for seals in waterproof enclosures and electronic device casings.

4. Industrial Equipment

- Enhances the functionality of gaskets and seals in machinery, reducing wear and tear during operation.

5. Medical Devices

- Ensures secure and hygienic bonding of seals in medical equipment and containers.

Types of Adhesive Tapes for Rubber Bonding

1. Acrylic Adhesive Tapes

- Known for their excellent UV resistance and durability.

- Ideal for outdoor applications and environments exposed to sunlight.

2. Silicone Adhesive Tapes

- Perfect for high-temperature applications.

- Provides strong adhesion to surfaces that are typically challenging for other adhesives.

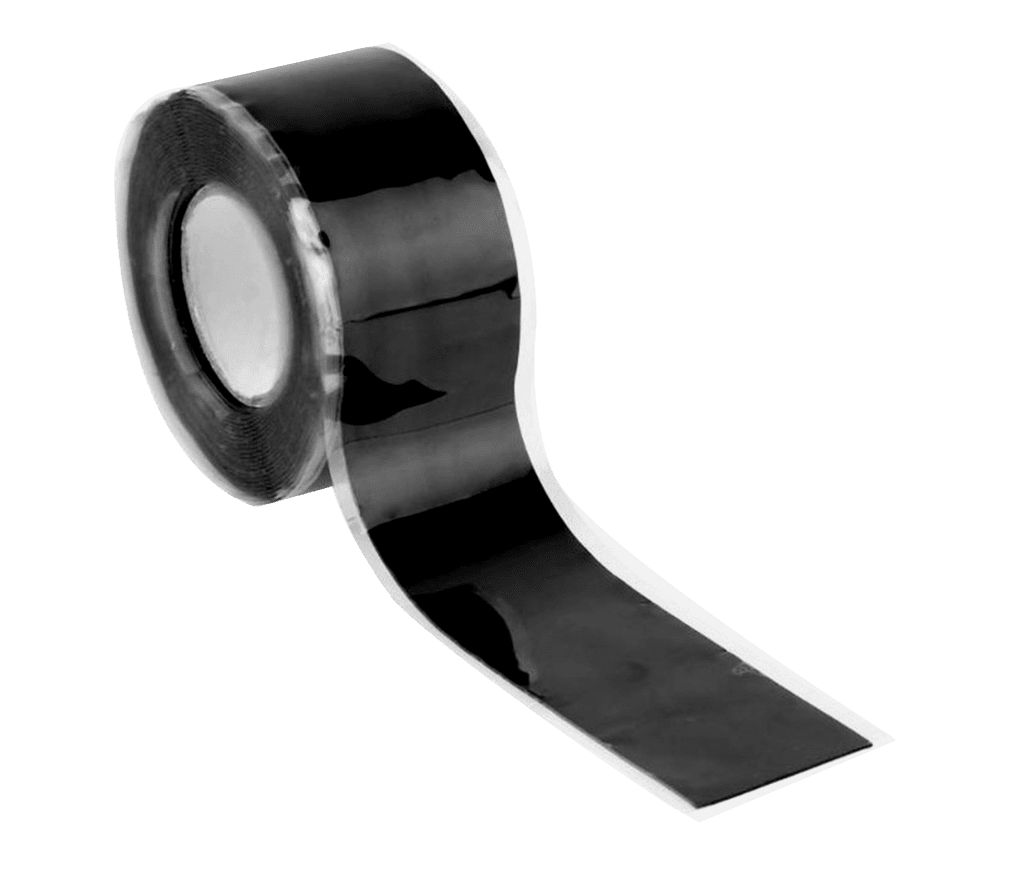

3. Rubber-Based Adhesive Tapes

- Cost-effective and versatile.

- Suitable for indoor applications with moderate temperature ranges.

4. Double-Sided Tapes

- Allows for discreet bonding, often used in applications requiring a clean appearance.

Key Considerations for Adhesive Tape Rubber Bonding

To ensure optimal performance, consider the following factors:

1. Surface Preparation

- Clean the surfaces to remove dirt, grease, and moisture for maximum adhesion.

2. Tape Selection

- Choose the adhesive tape based on environmental conditions, surface material, and application requirements.

3. Bonding Pressure

- Apply consistent pressure to ensure a strong and even bond.

4. Temperature Conditions

- Ensure the bonding process occurs within the recommended temperature range for the adhesive tape.

5. Compatibility

- Verify the compatibility of the adhesive tape with the specific rubber material and substrate.

Why Choose Rubber Seals and Gaskets for Adhesive Tape Bonded Products?

At Rubber Seals and Gaskets, we specialize in manufacturing high-quality rubber seals and gaskets designed for adhesive tape bonding. Here’s what sets us apart:

- Custom Solutions: Tailored products to meet unique application needs.

- High-Quality Materials: Use of premium-grade rubber and adhesive tapes for unmatched performance.

- Expert Guidance: Assistance in selecting the right adhesive tape and rubber combination for your project.

- Sustainability: Eco-friendly manufacturing processes with minimal waste.

Conclusion

Adhesive tape rubber bonding is a cutting-edge innovation that enhances the efficiency, durability, and versatility of rubber seals and gaskets. Whether you’re in the automotive, construction, or electronics industry, this bonding technique offers a seamless, cost-effective solution for a wide range of applications.

Explore the advanced adhesive tape rubber bonding solutions available at Rubber Seals and Gaskets. Contact us today to learn how we can help you achieve superior sealing and bonding results for your specific requirements.

FAQs

Yes, in many applications, adhesive tape bonding can replace screws, rivets, and liquid adhesives for a cleaner and more efficient solution.

The longevity depends on the quality of the adhesive tape and environmental conditions. Properly applied adhesive tape bonds can last for years.

Yes, tapes like acrylic adhesive tapes are designed to withstand outdoor elements such as UV radiation and moisture.

Choose Rubber Seals and Gaskets for reliable and innovative sealing solutions!