Description

| Stainless Steel: | Seals Ring | Api: | Gasket |

| Wellhead: | Ring Joint Gasket | Carbon Stell: | Gasket |

Standard: API 6a

Temperature: -200~800(℃)

Metal: Gasket

Industry: Oil And Gas

High Light: Asme B16.20 Soft Iron Ring Joint Gasket, HB90 soft iron ring gasket, Asme B16.20 ring joint flange

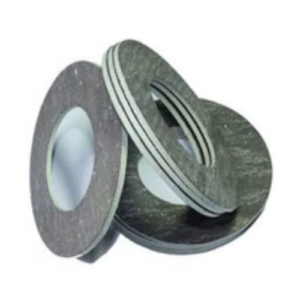

Ring Joint Gasket (RTJ) Asme B16.20 in Pipe high pressure and high temperature

Ring joint gaskets come in two basic types, an oval cross section and an octagonal cross section. These basic shapes are used in pressures up to 10,000 psi (64 MPa). The dimensions are standard- ized and require specially grooved flanges. The octagonal cross section has a higher sealing efficiency than the oval and would be the preferred gasket. However, only the oval cross section can be used in the old type round bottom groove. The newer flat bottom groove design will accept either the oval or the octagonal cross section. The sealing surfaces on the ring joint grooves must be smoothly finished to 63 micro inches and be free of objectionable ridges, tool or chatter marks. RTJ assemblies seal by an initial line contact or an edging action as the compressive forces are applied. The hardness of the ring should always be less than the hardness of the flanges to prevent flange deformation. Dimensions for standard ring joint gaskets and grooves are covered in ASME B16.20 and API 6A, API 17D and ASME B16.5/B16.20.

we supplies ring joint gaskets (RTJ Gasket) with the hardness numbers as follows:

| Common Materials | |||

| Material | HB Hardness | Temperature Limitations | Identification |

| Soft Iron | 90 | -60 to +400 °C | D |

| Low carbon steel | 120 | -40 to +500°C | S |

| 4%-6% Cr ½% Mo:F5 | 130 | -125 to +500°C | F5 |

| Stainless steel 304/304L | 160 | -250 to +650°C | S304 or 304L |

| Stainless steel 316/316L | 160 | -196 to +800°C | S316 or 316L |

| Stainless steel 321 | 160 | -250 to +870°C | S321 |

| Stainless steel 347 | 160 | -250 to +870°C | S347 |

| Stainless steel 410 | 170 | -20 to +500°C | S410 |

| Inconel 625 | – | 1000°C | 625 |

| Incoloy 825 | – | 1000°C | 825 |

| Hastelloy C-276 | – | 1000°C | C-276 |

| Duplex | – | 800°C | S31803 |

| Titanium | – | 540°C | TI |

We specializes in ring joint gasket, including ring gasket in R, RX, BX, IX types, lens gasket, weld ring gasket and bonnet gasket(according to client’s drawing). The metal gasket designed for use in high pressure, high temperature application necessitated the need for a high integrity seal. Our products are widely used in flat gate valve, Christmas tree, pipeline fittings, flange, high pressure vessel, oil &gas industry, wellhead assembly, petrochemical industry and the like.

We can offer more than 30 kinds of materials, such as 321SS, 347SS, 316SS, 304SS, Inconel 625, Monel 400, INCOLY 825, Nickel 200, Duplex F44, soft iron, low carbon steel and so on. We could produce the maximum outside diameter is 2500mm.

There’s a variety of material can be selected for a ring gasket according to a different application.

Check as below:

Soft Iron, Low Carbon Steel, Stainless Steel 304, Stainless Steel 304L, Stainless Steel 316, Stainless Steel 316L, Stainless Steel 321, Stainless Steel 347, Stainless Steel 410, Aluminum, Copper, Brass, Nickel 200, Monel 400, Inconel 600, Hastelloy B2, Titanium (see more information in our products catalog)

Ring joint gaskets are widely used in refinery, petrochemical and oil field drilling industries. and the rings are generally used for high pressure and high-temperature applications.