Description

| Carbon Steel: | Gasket | ||

| Metal: | Seals Ring | ||

| Temperature: | -200~800(℃) | Material: | Stainless Steel |

| Manufacturing Process: | CNC Leather | Raw Material: | Soft Iron |

High Light: SS304 Lens ring gasket, R30 copper ring gasket, SS304 copper ring gasket

lens GASKET WELLHEAD OILFIELD API GASKETS RTJ FLANGE

Materials

| SHORT NAME | MATERIAL NUMBER | NORM |

| C22.8 | 1.0460 | DIN 17243 |

| P245GH | 1.0352 | DIN EN 10222-2 |

| X6CrNi MoTi 7-12-2 | 1.4571 | DIN EN 10088-1 |

| X6CrNiTi18-10 | 1.4541 | DIN EN 10088-1 |

Description

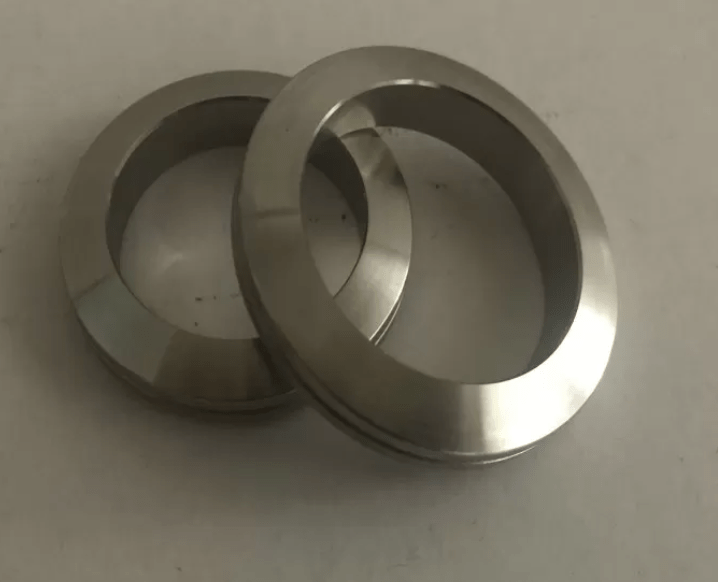

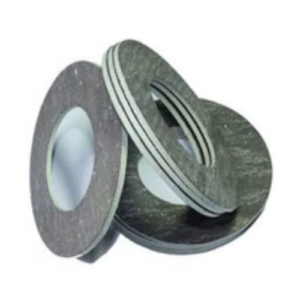

Lens gaskets, also known as sealing lenses or high-pressure lenses are fully metallic, turned sealing elements. Lens gaskets are mainly used in high pressure applications and specifically in pipeline flanges. The machined flange surfaces form a cone segment with an opening angle of 140°. The spherical zone of the lens connects here to the cone surfaces of the flange. Lens gaskets are not sensitive to overloading; an increase of the forces leads to an increase of sealing surface, which means that the surface pressure does not increase proportionally. It is re- commended that the hardness of the gasket is lower than that of the flange since the lens sealing surfaces easily deform. Experience has shown that even if the materials are the same, the plasticity of the lens gaskets is significantly more pronounced. Normally, the welding neck flange of the associ-ated pressure stage specified in DIN EN 1092-1 is used; other, equivalent flanges are, however, permissible. A roughness of Rz <= 6.3 in radial direction is necessary for the sealing sur-faces. The flange and the gaskets have to have an accurately treated surface without scratches and damage. In addition to the standardised lens gaskets specified in DIN 2696, an addi-tional system with spherical zones as sealing surfaces is used – mostly in the chemical sector and device construction. Detailed information about this system can be found in the respective company standard.

Properties

- High technical tightness

- Complies with TA Luft 2002 [VDI 2440/2200] leakage requirements

- Good handling, mechanically stable

- Blow-out resistant

- Very good handling during transport, installation and dismantling

- Individual marking of each gasket on the outer edge

Applications

- For pipeline and device construction

- For high internal pressures and/or high temperatures

- For flanges from DN 10-200 and PN 63-400

- For vacuum

Product Range & Designs

The geometry of lens gaskets is described in DIN 2696. There are two lens gasket series specified that correspond with the two series of pipe connection dimensions.