Description

| Carbon Steel: | Gasket | Stainless Steel: | Seal |

| Metal: | Seals Ring | Soft Iron: | Gasket |

High Light: SS304L RX Ring Joint Gasket, HB160 ring type joint gasket, SS304L ring type joint gasket

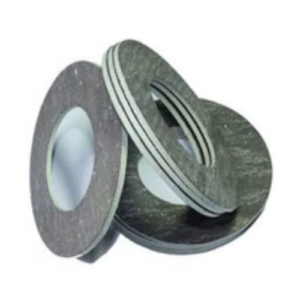

The RX type RTJ gasket is manufactured in accordance to API 6A and ASME B16.20 to suit API 6B and ASME/ANSI B16.5 flanges. The RX is a pressure energized version of the R octagonal gasket and fits the R type flat bottomed groove. The RX has an increased height and utilizes the internal system pressure to energize and improve the seal as internal pressure increases. Some RX sizes have a pressure relief hole to equalize pressure on both sides of the sealing faces.

Ring joint gaskets (RTJ Gasket) according to API 6A and ASME B16.20 for numerous industrial applications based on the customer required specifications with corrosive protection using electroplated zinc or alternate material coating of up to 0.0003” thickness.

Type RX

–NB1 1/2″ to 24″ Class Rating 720 to 5000 ASME B16.20

–NB26″ to 36″ Class Rating 300 to 900 ASME B16.20 Series A

–NB1 1/2″ to 20″ Class Rating API 6A

Style RX type RTJ gaskets are manufactured in accordance with both API 6A and ASME B16.20 to suit API 6B and ASME/ANSI B16.5 flanges.

Style RX is a pressure-energized adaptation of the standard Style R gasket. The RX is designed to fit the same groove design as a standard Style R, making the joints interchangeable. The modified design uses a pressure-energized effect that improves the efficiency of the seal as the internal pressure of the system increases.

In order to reduce turbulent flow in adjoining flanges and prevent gasket/flange erosion Goodrich Gasket offers SPECIAL R, RX type joints with PTFE inserts. Goodrich Gasket also offers Nitrile Rubber coated ring joint gaskets (RTJ Gasket) used in pressure testing applications and as a protection for flange grooves and surfaces. Ring joint flanges with different ring groove diameters are sealed by Transition Ring joints, a different size and same PCD combination rings. Blind Ring joints, a standard ring joint with integral solid metallic centers blanks off flanges and pipe work. Flange Guards of closed cell neoprene foam readily compress under load protecting outside diameter of Ring joints in corrosive environments.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RING NO. | PRESSLURE ALASSES, API 6B | PITCH DLAMETER OF RING P |

OUTSIDE DLAMETER OF RING 0D |

WIDTH OF RING A |

HELCHT OF RING H |

WEIGHT Ibs. |

|||

| 720-960and 2000[Note(1)] |

2900[Note(1)] | 3000 | 5000 | ||||||

| Rx20 | 1 1/2 | – | 1 1/2 | 1 1/2 | 68.26 | 76.2 | 8.73 | 19.05 | 0.527 |

| Rx23 | 2 | – | – | – | 82.55 | 93.27 | 11.91 | 25.4 | 1.15 |

| Rx24 | – | – | 2 | 2 | 95.25 | 105.97 | 11.91 | 25.4 | 1.33 |

| Rx25 | – | – | – | 3 1/8 | 101.6 | 109.54 | 8.73 | 19.05 | 1.42 |

| Rx26 | 2 1/2 | – | – | – | 101.6 | 111.92 | 11.91 | 25.4 | 1.5 |

| Rx27 | – | – | 2 1/2 | 2 1/2 | 107.95 | 118.27 | 11.91 | 25.4 | 1.73 |

| Rx31 | 3 | – | 3 | – | 123.83 | 134.54 | 11.91 | 25.4 | 1.91 |

| Rx35 | – | – | – | 3 | 136.53 | 147.24 | 11.91 | 25.4 | 2.09 |

| Rx37 | 4 | – | 4 | – | 149.23 | 159.94 | 11.91 | 25.4 | 2.27 |

| Rx39 | – | – | – | 4 | 161.93 | 172.64 | 11.91 | 25.4 | 2.54 |

| Rx41 | 5 | – | 5 | – | 180.98 | 191.69 | 11.91 | 25.4 | 2.72 |

| Rx44 | – | – | – | 5 | 193.68 | 204.39 | 11.91 | 25.4 | 2.96 |

| Rx45 | 6 | – | 6 | – | 211.14 | 281.85 | 11.91 | 25.4 | 3.66 |

| Rx46 | – | – | – | 6 | 211.14 | 222.25 | 13.49 | 28.58 | 8.56 |

| Rx47 | – | – | – | 8(2) | 228.6 | 245.27 | 19.84 | 41.28 | 3.79 |

| Rx49 | 8 | – | 8 | – | 269.88 | 280.59 | 11.91 | 25.4 | 5.36 |

| Rx50 | – | – | – | 8 | 269.88 | 283.37 | 16.67 | 31.75 | 4.56 |

| Rx53 | 10 | – | 10 | – | 323.85 | 334.57 | 11.91 | 25.4 | 6.45 |

| Rx54 | – | – | – | 10 | 323.85 | 337.34 | 16.67 | 31.75 | 5.36 |

| Rx57 | 12 | – | 12 | – | 381 | 391.72 | 11.91 | 25.4 | 26.4 |

| Rx63 | – | – | – | 14 | 419.1 | 441.72 | 26.99 | 50.8 | 6.63 |

| Rx65 | 16 | – | – | – | 469.9 | 480.62 | 11.91 | 25.4 | 9.39 |

| Rx66 | – | – | 16 | – | 469.9 | 483.39 | 16.67 | 31.75 | 7.52 |

| Rx69 | 18 | – | – | – | 533.4 | 544.12 | 11.91 | 25.4 | 20.14 |

| Rx70 | – | – | 18 | – | 533.4 | 550.07 | 19.84 | 41.28 | 11.63 |

| Rx73 | 20 | – | – | – | 584.2 | 596.11 | 13.49 | 31.75 | 22.1 |

| Rx74 | – | – | 20 | – | 584.2 | 600.87 | 19.84 | 41.28 | 0.79 |

| Rx82 | – | 1 | – | – | 57.15 | 67.87 | 11.91 | 25.4 | 0.88 |

| Rx84 | – | 1 1/2 | – | – | 63.5 | 74.22 | 11.91 | 25.4 | 0.88 |

| Rx85 | – | 2 | – | – | 79.38 | 90.09 | 13.49 | 25.4 | 1.79 |

| Rx86 | – | 2 1/2 | – | – | 90.49 | 103.58 | 15.08 | 28.58 | 1.98 |

| Rx87 | – | 3 | – | – | 100.03 | 113.11 | 15.08 | 28.58 | 3.22 |

| Rx88 | – | 4 | – | – | 123.83 | 139.29 | 17.46 | 31.75 | 2.98 |

| Rx89 | – | 3 1/2 | – | – | 114.3 | 129.78 | 18.26 | 31.75 | 6.82 |

| Rx90 | – | 5 | – | – | 155.58 | 174.63 | 19.84 | 44.45 | 17.1 |

| Rx91 | – | 10 | – | – | 260.35 | 286.94 | 30.18 | 45.24 | 3.31 |

| Rx99 | 8(2) | – | 8(2) | – | 234.95 | 245.67 | 11.91 | 25.4 | – |

| Rx201 | – | – | – | 1 3/8 | 46.04 | 51.46 | 5.74 | 11.3 | – |

| Rx205 | – | – | – | 1 13/16 | 57.15 | 62.31 | 5.56 | 11.1 | – |

| Rx210 | – | – | – | 2 9/16 | 88.9 | 97.63 | 9.53 | 19.05 | – |

| RX215 | – | – | – | 4 1/16 | 130.18 | 140.89 | 11.91 | 25.4 | –

|

Standard Gasket Material

Carbon Steel

Commercial quality sheet steel with an upper temperature limit of approximately 1000º F., particularly if conditions are oxidizing. Not suitable for handling crude acids or aqueous solutions of salts in the neutral or acid range. A high rate of failure may be expected in hot water service if the material is highly stressed, Concentrated acids and most alkalies have little or no action on iron and steel gaskets which are used regularly for such services.

304 Stainless Steel

· An 18-8 (Chromium 18-20%, Nickel 8-10%) Stainless with a maximum recommended working temperature of 1400º F

· At least 80% of applications for non-corrosive services can use Type 304 Stainless in the temperature range of -320 F to 1000º F.

· Excellent corrosion resistance to a wide variety of chemicals.

· Subject to stress corrosion crackling and to intergranular corrosion at temperatures between 800º F to 1500º F in presence of certain media for prolonged periods of time.

316 Stainless Steel

· An18-12 Chromium-Nickel steel with approximately 2% of Molybdenum added to the straight 18-8 alloy which increases its strength at elevated temperatures and results in somewhat improved corrosion resistance.

· Has the highest creep strength at elevated temperatures of any conventional stainless type.

· Not suitable for extended service within the carbide precipitation range of 800º F to 1650º F. when corrosive conditions are severe.

· Recommended maximum working temperature of 1400º F.

316L Stainless Steel

· Continuous maximum temperature range of 1400º F -1500º F.

· Carbon content held at a maximum of .03%.

· Subject to a lesser degree of stress corrosion cracking and also to intergranular corrosion than Type 316.

321 Stainless Steel

· An 18-10 Chromium-Nickel steel with a Titanium addition.

· Type 321 stainless has the same characteristics as Type 347.

· The recommended working temperature is 1400º F to 1500º F. and in some instances 1600º F.

347 Stainless Steel

· An 18-10 Chromium-Nickel steel with the addition of Columbium.

· Not as subject to intergranular corrosion as is Type 304.

· Is subject to stress corrosion.

· Recommended working temperature of 1400º F -1500º F and in some instances to 1700º F.

410 Stainless Steel

· A 12% Chromium steel with a maximum temperature range of 1200º F. to 1300º F.

· Used for applications requiring good resistance to sealing at elevated temperatures.

· Is not recommended for use where severe corrosion in encountered but is still very useful for some chemical application.

· May be used where dampness, alone or coupled with chemical pollution, causes steel to fail quickly.

502/501(F5)

· 4-6% Chromium and 1/2% Molybdenum alloyed for mild corrosive resistance and elevated service. Maximum working temperature is 1200º F.

· If severe corrosion is anticipated, a better grade of stainless steel would probably be a better choice. Becomes extremely hard when welded.

Admiralty

· Arsenical Admiralty 443 has 71% Copper, 28% Zinc, 1% Tin and trace amounts of Arsenic.

· High corrosive resistance, holds up extremely well against salt and brackish waters, and water containing sulfides.

· Recommended maximum working temperature of 500º F.

· Ideal for carrying corrosive cooling waters at relatively high temperatures.

Alloy 20

· 45% Iron, 24% Nickel, 20% chromium, and small amounts of Molybdenum and Copper.

· Maximum temperature range of 1400º F -1500º F.

· Developed specifically for applications requiring resistance to corrosion by sulfuric acid.

· Brinell hardness is about 160.

Aluminum

· Alloy 110 is commercially pure (99% minimum).

· Its excellent resistance and workability makes it ideal for double jacketed gaskets.

· For solid gaskets, stronger alloys like 5052 and 3003 are used.

· Maximum continuous service temperature of 800º F.

Brass

· Yellow brass 268 has 66% Copper and 34% Zinc.

· Offers excellent to good corrosion resistance in moist environments, but is not suitable for such materials as acetic acid, acetylene, ammonia, and salt. Maximum recommended temperature limit of 500 F.

Copper

· Nearly pure copper with trace amounts of silver added to increase its working temperature.

· Recommended maximum continuous working temperature of 500º F.

Cupro Nickel

· Contains 69% Copper, 30% Nickel and small amounts of Manganese, Zinc and Iron.

· It is mostly used in sea water applications, where lesser resistant alloys rapidly deteriorate.

· Maximum recommended temperature limit 500º F.

Hastelloy B

· 26-30% Molybdenum, 62% Nickel and 4-6% Iron.

· Maximum temperature range of 2000º F. resistant to hot, concentrated hydrochloric acid.

· Also resists the corrosive effects of wet hydrogen chlorine gas, sulfuric and phosphoric acids and reducing salt solutions.

· Useful for high temperature strength.

Hastelloy C-276

· 16-18% Molybdenum, 13-17.5% Chromium, 3.7-5.3% Tungsten, 4.5-7% Iron and the balance is Nickel. Maximum temperature range of 2000º F.

· Very good in handling corrosives.

· High resistance to cold nitric acid of varying concentrations as well as boiling nitric acid up to 70% concentration.

· Good resistance to hydrochloric acid and sulfuric acid.

· Excellent resistance to stress corrosion cracking.

Inconel 600

· Recommended working temperatures of 2000º F. and is some instances 2150º F.

· Is a nickel base alloy containing 77% Nickel, 15% Chromium and 7% Iron, Excellent high temperature strength.

· Frequently used to overcome the problem of stress corrosion.

· Has excellent mechanical properties at the cryogenic temperature range.

Incoloy 800

· 32.5% Nickel, 46% Iron, 21% Chromium, resistant to elevated temperatures, oxidation and carburization. Recommended maximum temperature of 1600º F.

Monel

· Maximum temperature range of 1500º F.

· Contains 67% Nickel and 30% Copper.

· Excellent resistance to most acids and alkalies, except strong oxidizing acids.

· Subject to stress corrosion, cracking when exposed to fluorosilic acid, mercuric chloride and mercury, and should not be used with these media.

· With PTFE (Polytetrafluoroethylene), it is widely used for hydrofluoric acid service.

Nickel 200

· Recommended maximum working temperature is 1400º F. and even higher under controlled conditions. Corrosion resistance makes it useful in caustic alkalies and where resistance to corrosion, in structural applications, is a prime consideration.

· Does not have the all around excellent resistance of Monel.

Phosphor Bronze

· 90-95% Copper, 5-10% Tin and trace amounts of phosphorus.

· Maximum temperature range of 500º F.

· Maximum temperature range of 500º F.

· Limited to low temperature steam applications.

· Excellent corrosion resistance, but not suitable for acetylene, ammonia, chromic acid, mercury and potassium cyanide.

Titanium

· Maximum temperature range of 2000ºF.

· Excellent corrosion resistance even at high temperatures.

· Known as the “Best solution” to chloride ion attack.

· Resistant to nitric acid in a wide range of temperatures and concentrations.

· Most alkaline solutions have little if any effect upon it.

· Outstanding in oxidizing environments.