Description

Retaining mechanism as the name suggests has a very crucial role to play in the proper functioning of an inflatable seal. The entire purpose of an inflatable seal is defeated if it is not held in position perfectly. Different seal profiles require different kinds of retention mechanism. Rubber Seals & Gaskets can guide you in deciding and selecting the ideal retention mechanism to suit your application.

Retainer Types for Inflatable Seals

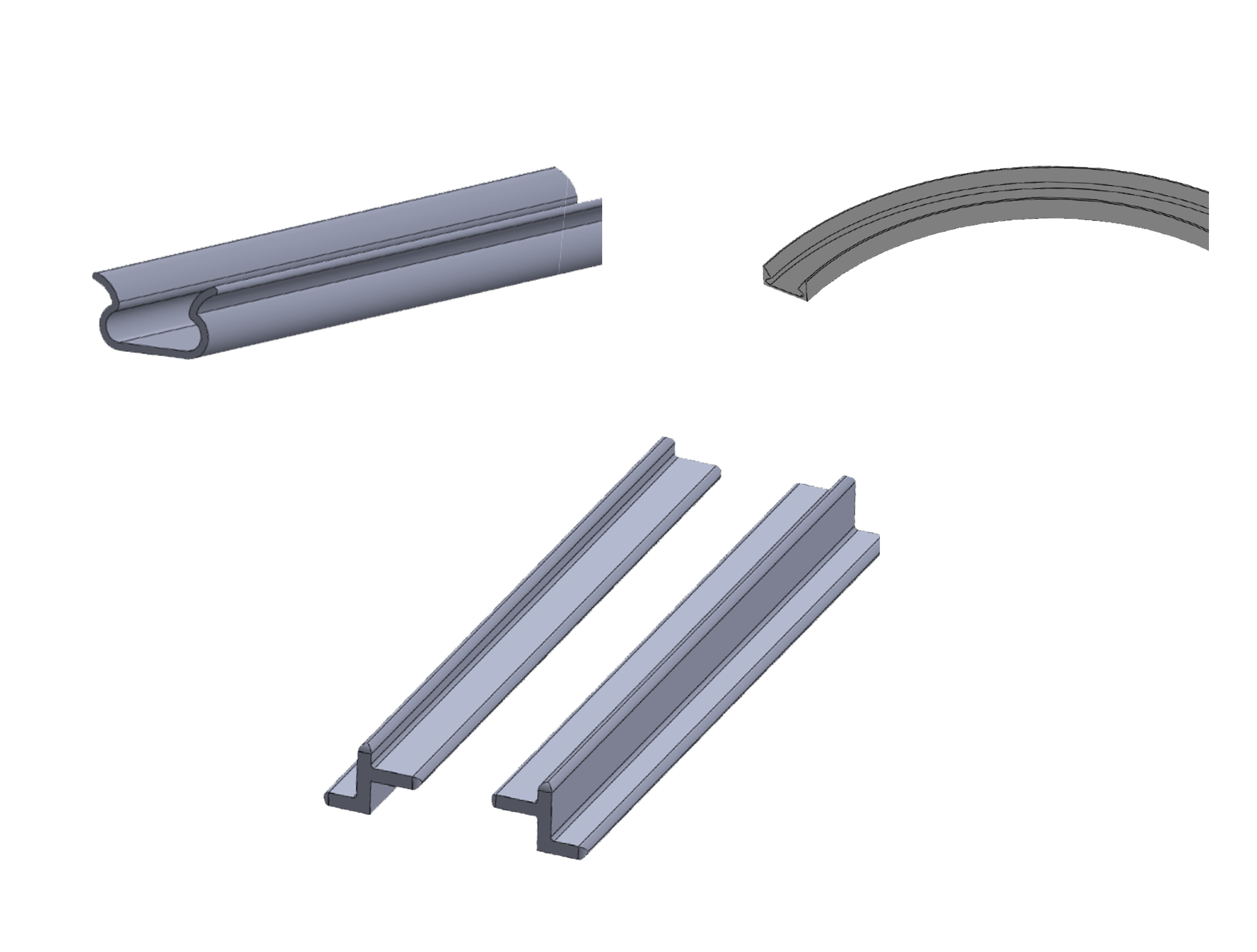

SNAP-IN TYPE

For type 3 (Snap-in) inflatable seal types, the snap-in retention system is suitable. This mechanism retains the seal’s foot structure. The seal’s foot is attached to the bottom, allowing the top to inflate. Together with the inflatable lock, we can provide this retention function for additional charges.

FOOT LOCK TYPE

The retention feature of the Foot Lock is recommended for inflatable seal profiles of type 2 (fasten in). Similar to retention of the Snap-in, the bottom is fixed here allowing the expansion of the Inflatable seal bulb. Nevertheless, the protection of the Foot Lock comes with an added advantage, which can be retro fitted in the design groove by drilling screws and bolts.

SNAP SLOT TYPE

This system of preservation has a body of rubber against a metal body. It is suitable for inflatable seal profiles of type 3 (Snap-in). The Snap Slot mechanism has rectangular dimensions in width and height as opposed to the Snap-in retention mechanism, allowing for easy installation. In any groove of the’ U ‘ channel it can be easily installed and no separate machining is necessary.

End Retention Mechanism

SINGLE SCREW PRESSURE PLATES

During inflation, pressure plates are used to keep the inflatable seal in the right position. For seals with a relatively small cross section, i.e. a limited width, single screw pressure plate is used. Such pressure plates are used for seals that match within grooves.

DOUBLE SCREW PRESSURE

For preserving inflatable seals with wider cross sections i.e. larger widths, double screw pressure plates are used. Also, for seals fitting within grooves, double screw pressure plates are used.

FIXED PRESSURE PLATE

Fixed pressure plates find their place in applications where they are not placed in grooves in inflatable seals. And thus, having a tight and powerful mechanism to keep the Inflatable Seal in place during periods of inflation and deflation becomes extremely important.