Description

For general, there are two main factors that define the Inflatable seal profile for an application, i.e. geometry and setting, where the seal will operate. Defining the application’s geometry involves defining what you plan to do physically in the application for the Inflatable Seal, and how you envisage the positioning of the Inflatable Seal in the specification. In other words, we need to know how much space there is to install the Inflatable Seal in the case, and how far the Inflatable Seal needs to “inflate” to reach the striking point. Rubber Seals & Gaskets extensively tests and uses the most suitable combinations of elastomers and tissue reinforcements to design and build the ideal seals for your application. Such combinations are chosen in response to your application’s geometric and environmental requirements. For Rubber Seals & Gaskets engineers, a sketch / drawing of your application is most helpful in determining the right inflatable seal for your product. You are not required to determine the materials to be used, because you define the output parameters of your application, this problem is solved through a collaborative effort between you and Rubber Seals & Gaskets engineers.

1 Environment

Understanding the atmosphere in which your inflatable seal can function, i.e. whether the environment is acidic, gaseous, liquid, chemically reactive, etc., is very important for you. This also involves deciding what solvents or liquids with the Inflatable Seal will come into contact. This will allow us to decide the most suitable raw material and compound for your inflatable seal. To understand the properties of different types of rubber, please refer to the Rubber Seals & Gaskets Elastomer Comparison Chart.

2 Differential Pressure

The second major factor that helps determine the optimal seal configuration for your application is the pressure felt by the inflatable seal. Differential pressure helps to assess what should be the seal’s internal pressure. The pressure differential may be positive or negative (vacuum). The conditions of pressure will allow us to opt for a structure that is reinforced or not reinforced. Higher pressure Inflatable seals usually require tissue-enhanced construction. If the differential pressure is less than 8-10 bar and the average periods of inflation are less than 5000 per year, there is no need for tissue reinforcement.

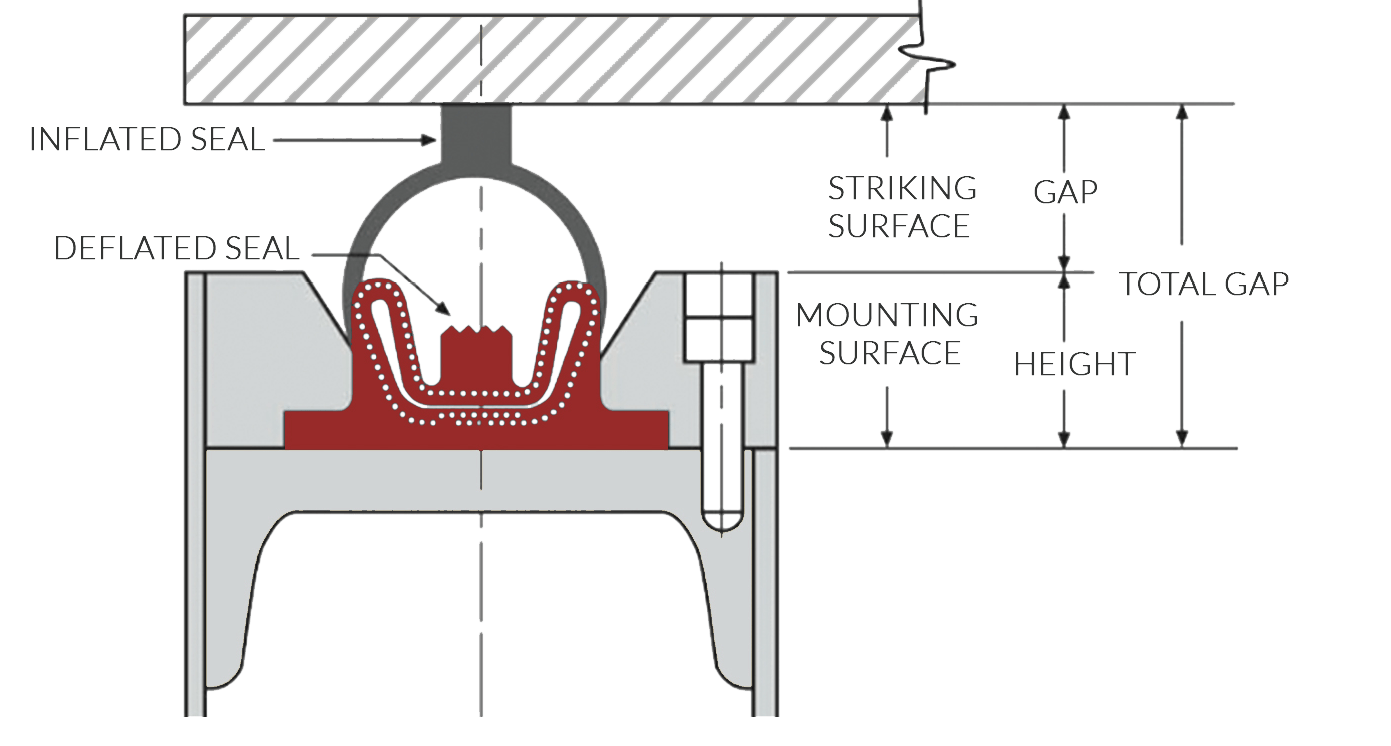

3 Seal Inflation Gap

Understanding how much inflation the Inflatable Seal needs up to the striking surface is important. This specification will allow us to select for your Inflatable seal the appropriate cross section. We may determine the type of seal expansion, geometry, etc. depending on the application and location of the inflatable seal.

4 Safety Mechanisms

Many applications require that the seal operation be precisely controlled or cycled when designing the inflatable seals. In such situations, it may be necessary to combine control boxes, valves, regulators, gauges, alarms, and compressors. If your application needs it, Rubber Seals & Gaskets can provide a control device. Understanding how much inflation is required by the seal up to the striking surface is important. This specification will allow us to select the right section for your seal. We may agree on the type of seal extension, geometry, etc. depending on the application and location of the seal.

PRESSURE SUPPLY

A. Air Collector

B. Pressure Relief Valve Filter

C. Non Return Valve

D. Pressure Gauge

E. Valve