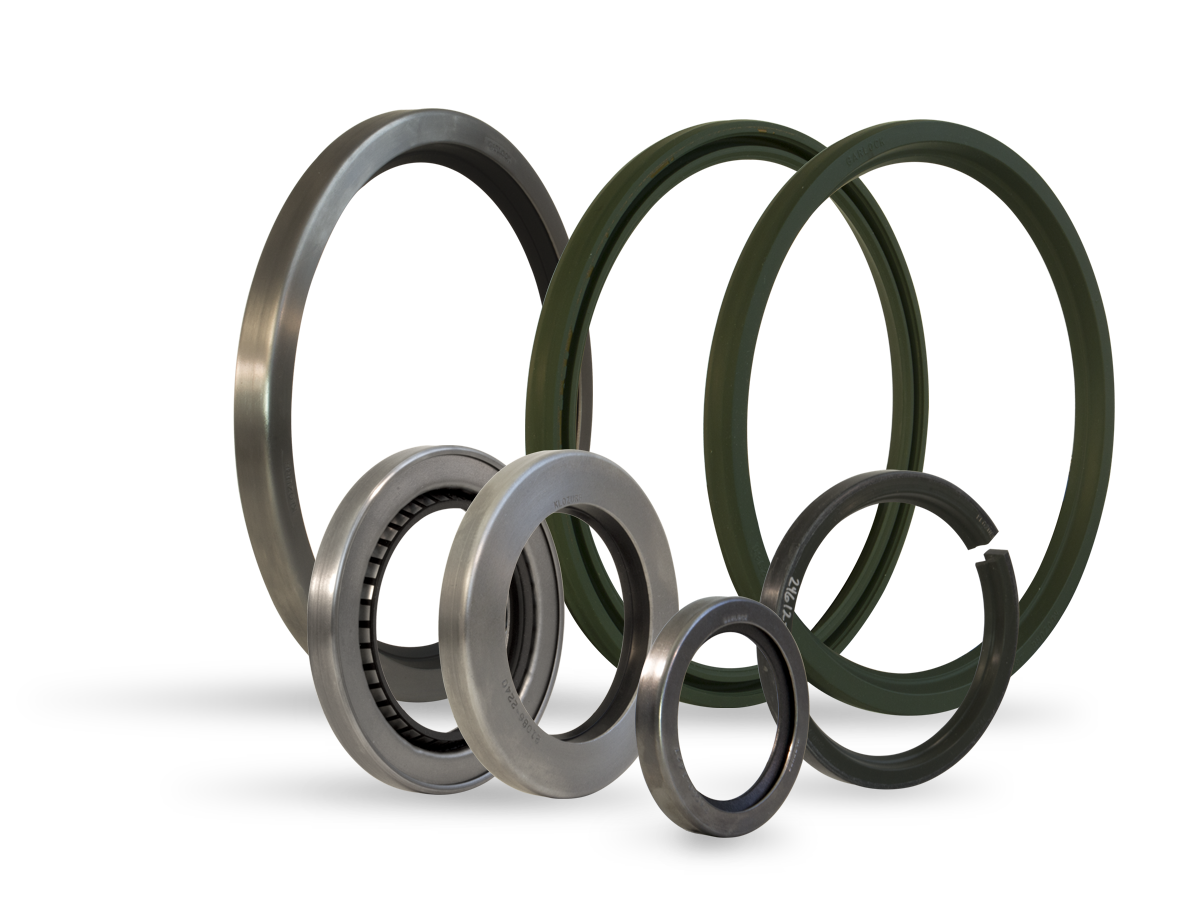

Custom Molded Shapes

At Diyak Rubber, our advanced molding capabilities allow us to custom mold any shape required, from prototype to production. High-precision molding machines provide compression, transfer and injection molding seamlessly. Our in-house mold making capabilities contribute to the highest quality parts.

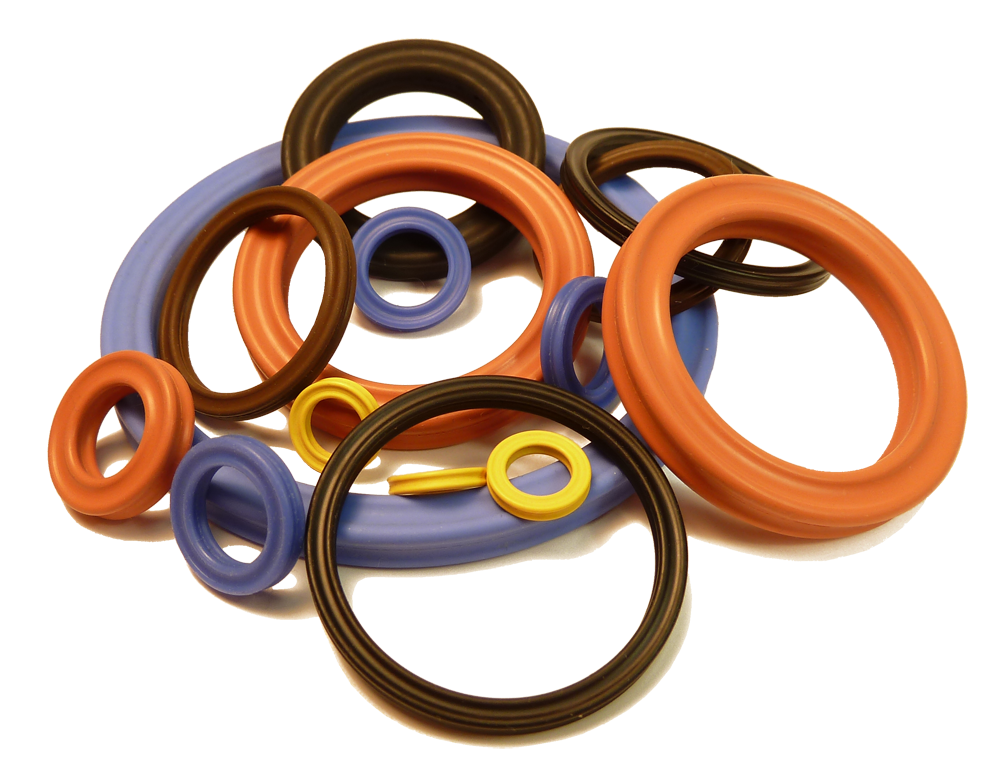

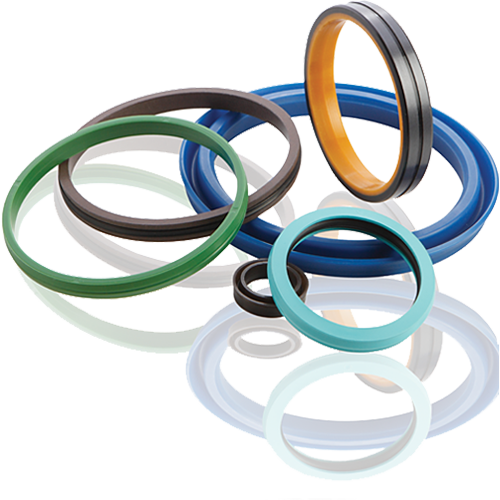

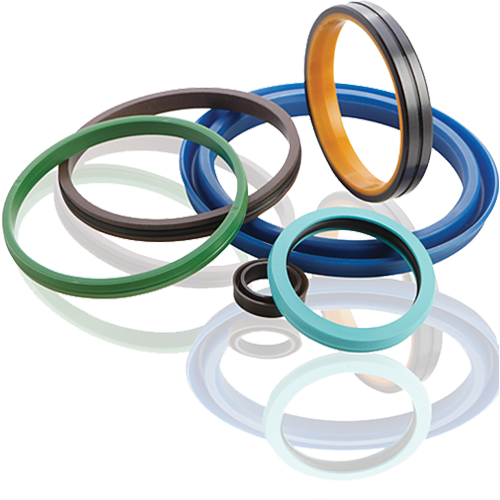

Popular Custom Molded Shapes

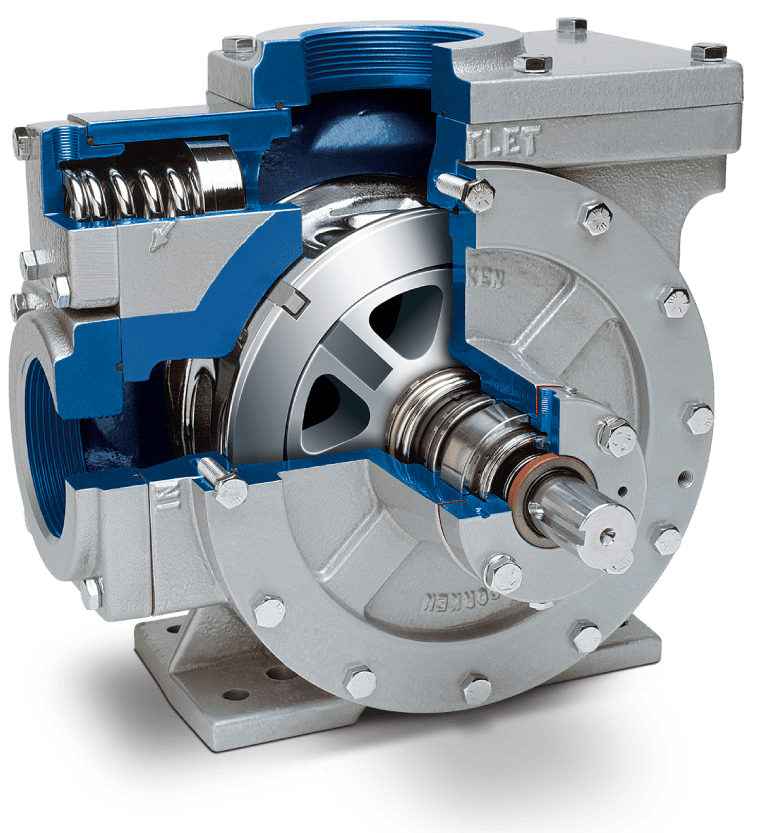

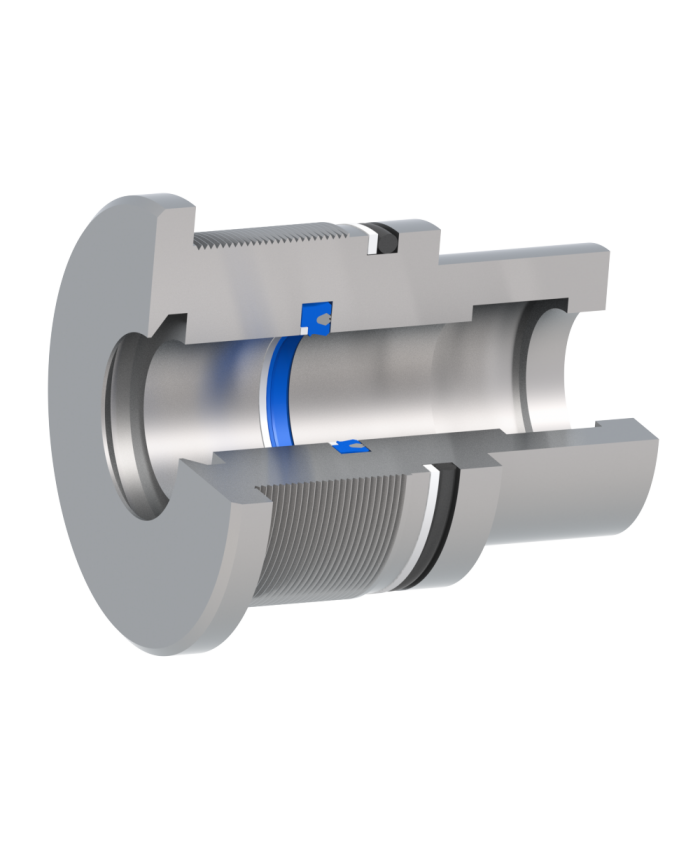

- Housing Seals

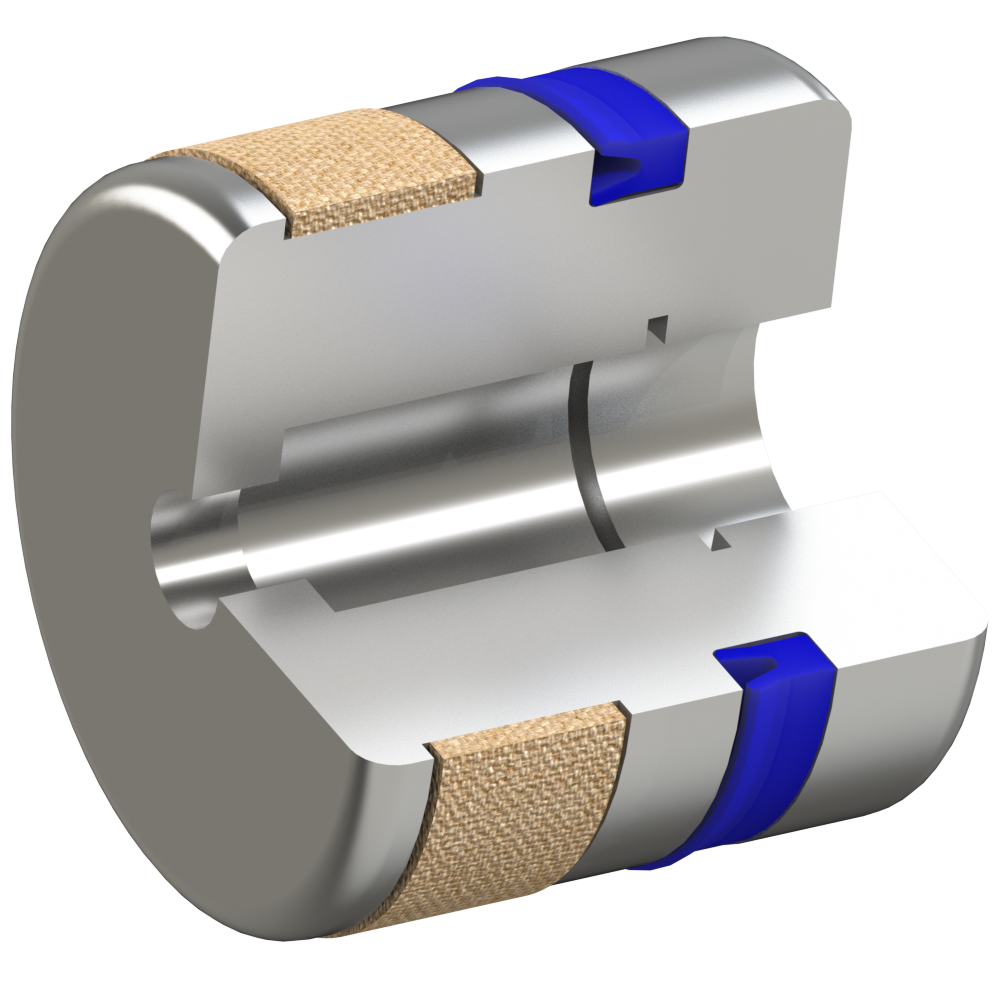

- Composite Seals

- Diaphragms

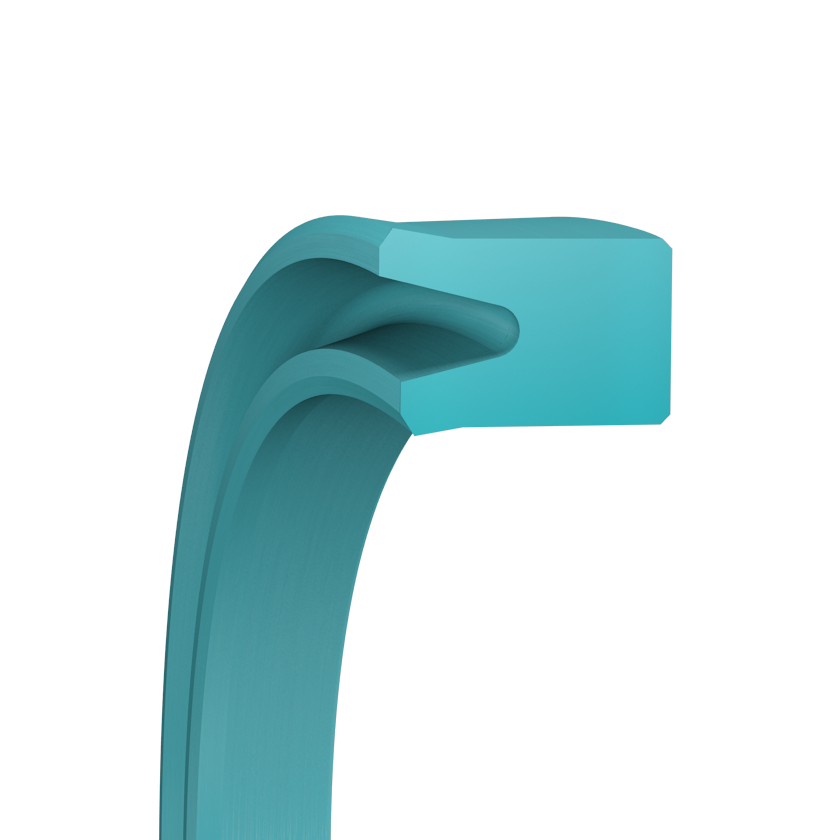

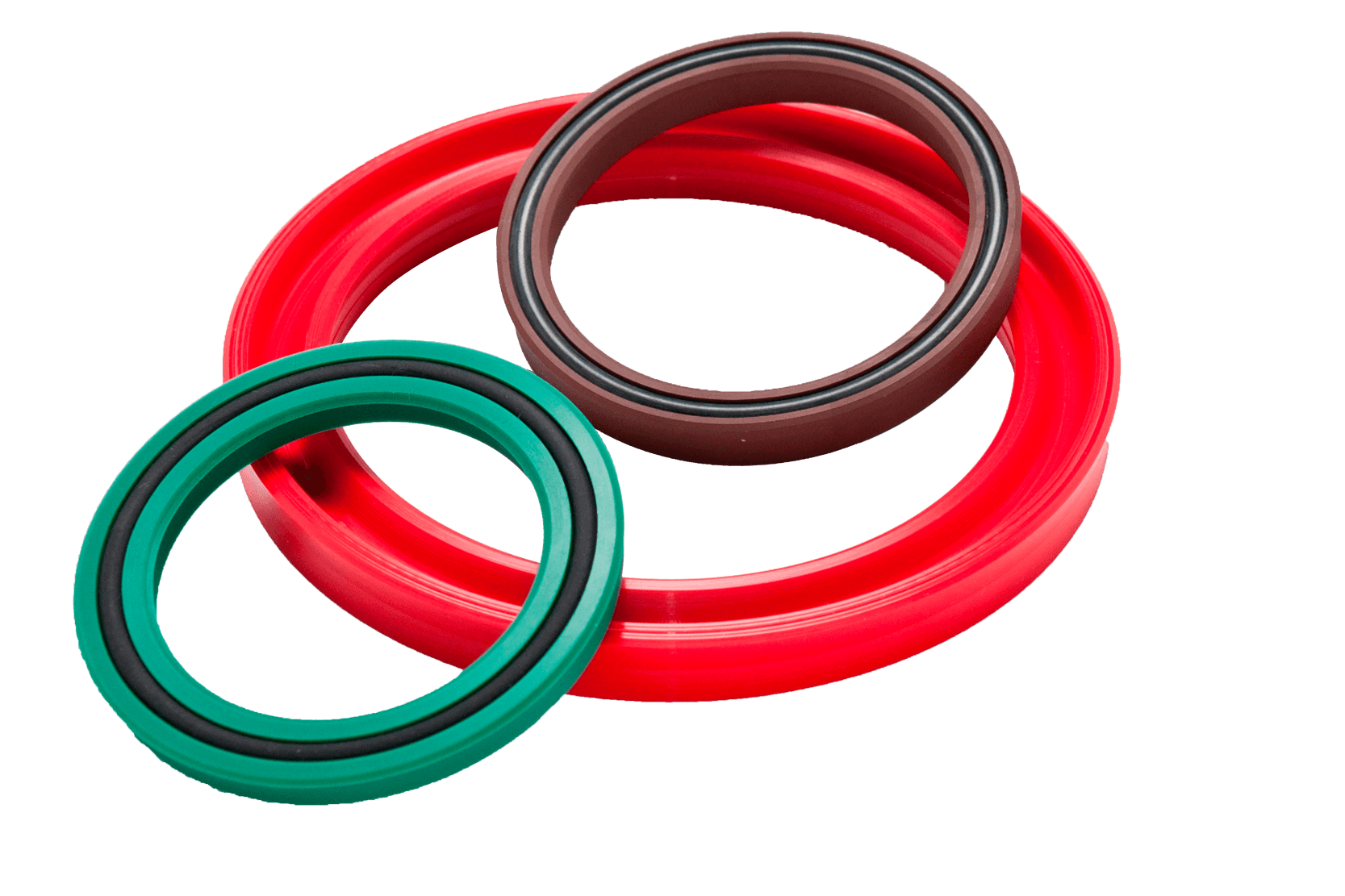

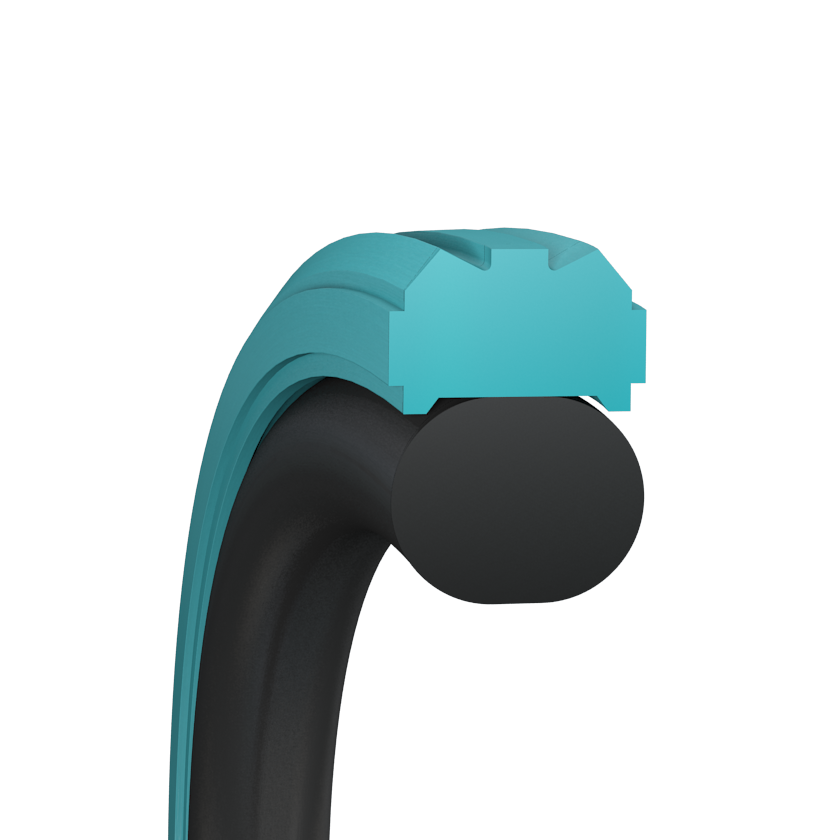

- U-Cup and Lip seals

- Piston seals

- Bushings

- Grommets and Poppets

- Connector seals

Advanced Molding Equipment

When properly prepared, the benefits include fulfillment of USP Class VI and ISO 10993 requirements, and can be sterilized with autoclave, gamma, ETO. Less than 30 day implant and long-term implant grades available. Medical grade pigments are also available.

Ethylene-Propylene

Diyak Rubber uses the latest technology and equipment for molding. Some of our most efficient molding processes include:

- Advance rubber injection machines

- High precision Liquid Silicone Rubber Injection (LSR)

- Vacuum compression and transfer presses

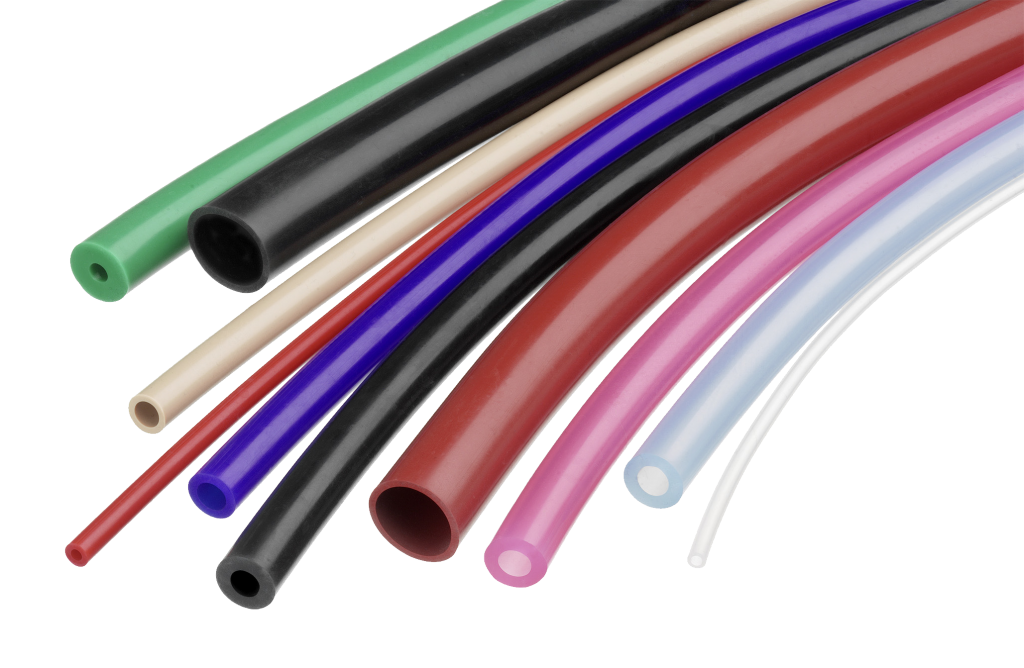

The Right Sealing Material

Diyak Rubber can produce your custom shapes and seals in a wide variety of materials, including:

- NBR (Nitrile): Fuel and oil resistance

- EPDM (Ethylene-Propylene): Weather and ozone resistance, water seals

- FKM (Fluorocarbon): Chemical resistance, low outgassing, high-temperature

- CR (Chloroprene): Some oil and weather resistance, Freon applications

- VMQ (Silicone): Low and high temperature resistance

- FVMQ (Fluorosilicone): Fuel resistance, low and high temperature resistance

- FFKM (Perfluoroelastomer): Highest chemical resistance