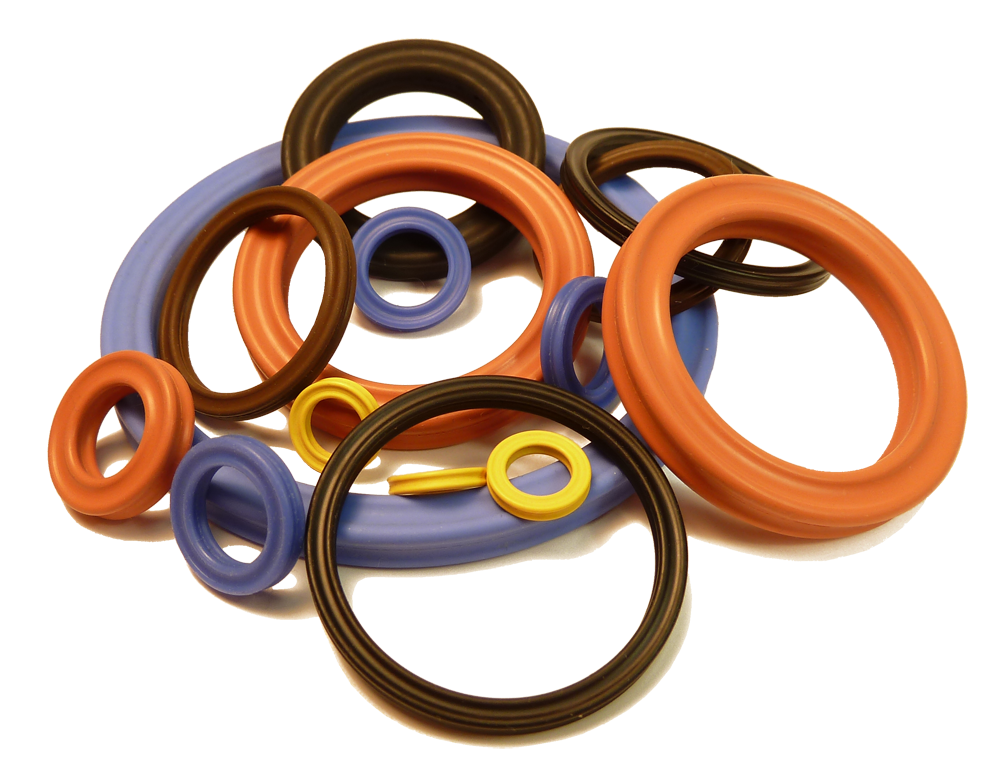

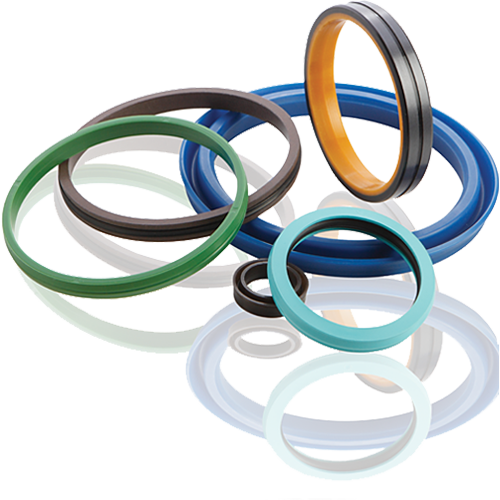

FEP Encapsulated O-Rings

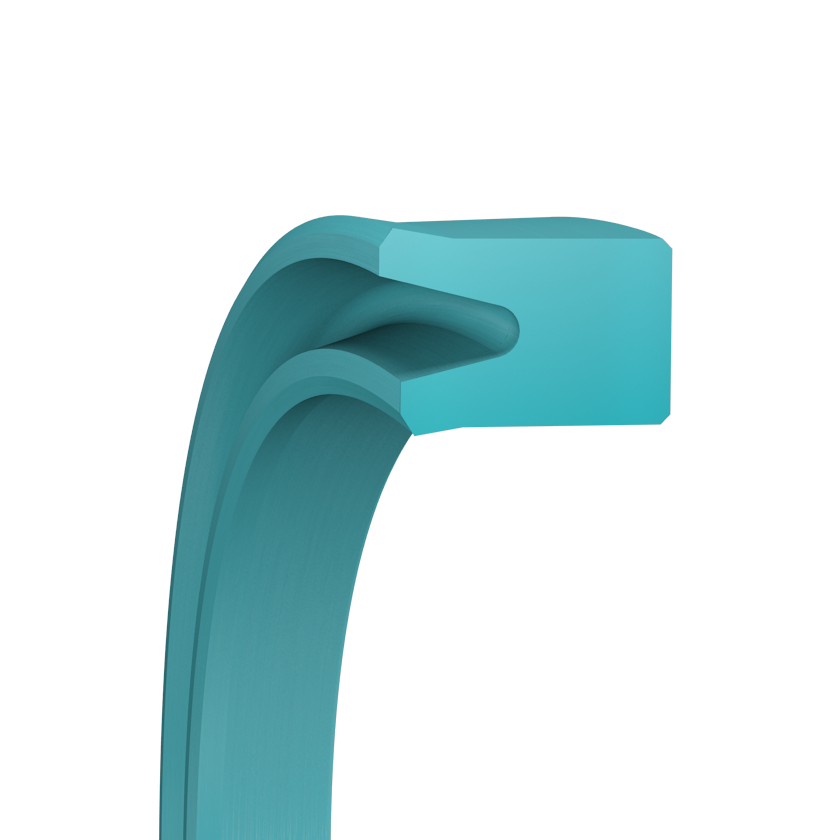

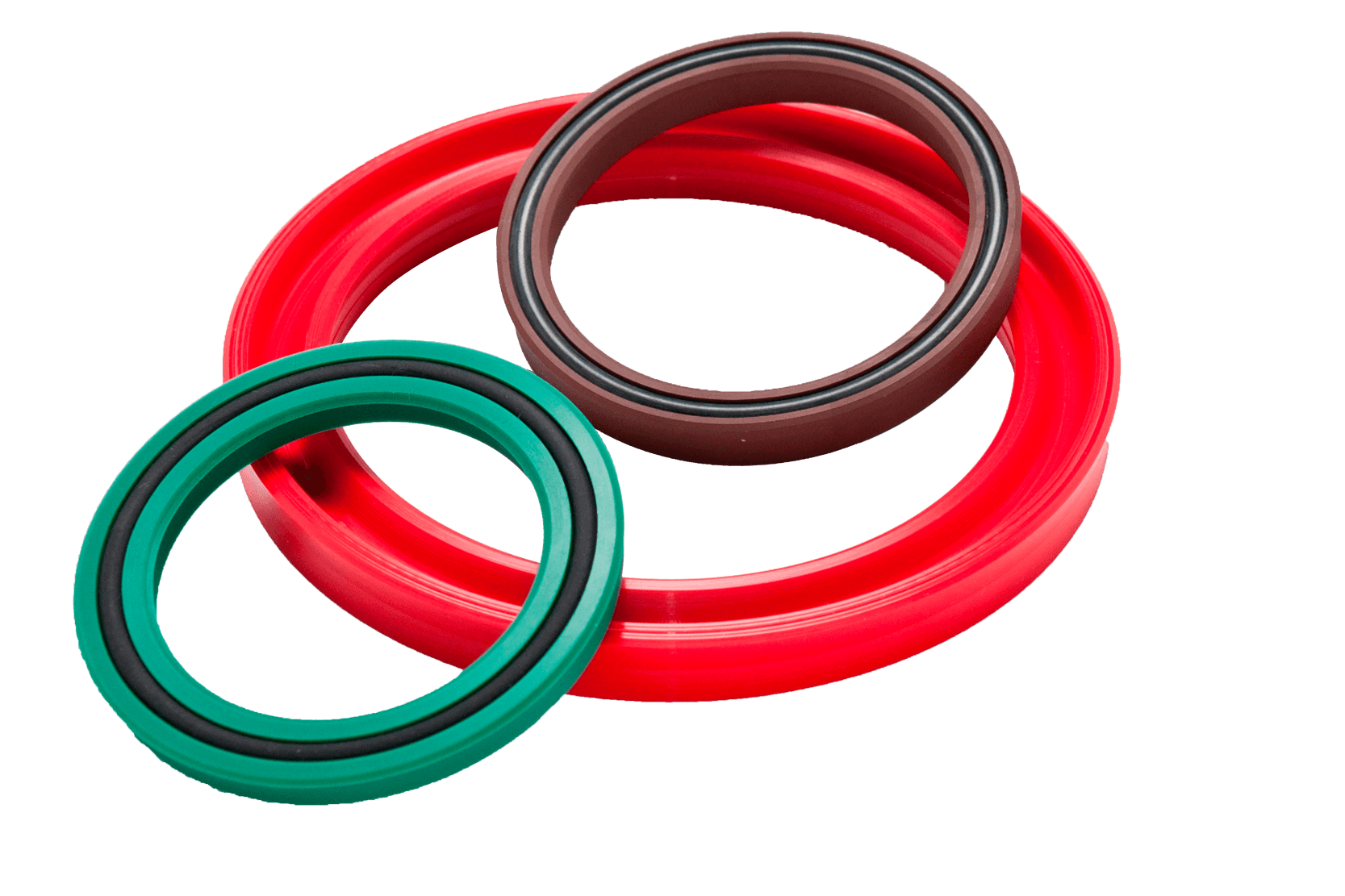

FEP Encapsulated O-Rings are ideal in static applications, but in many situations have also been used in dynamic applications like mechanical seals. In dynamic applications they do have good wear resistance. FEP O-Rings are FDA Compliant which can take Pressure in Vacuum application upto 10,000 psi

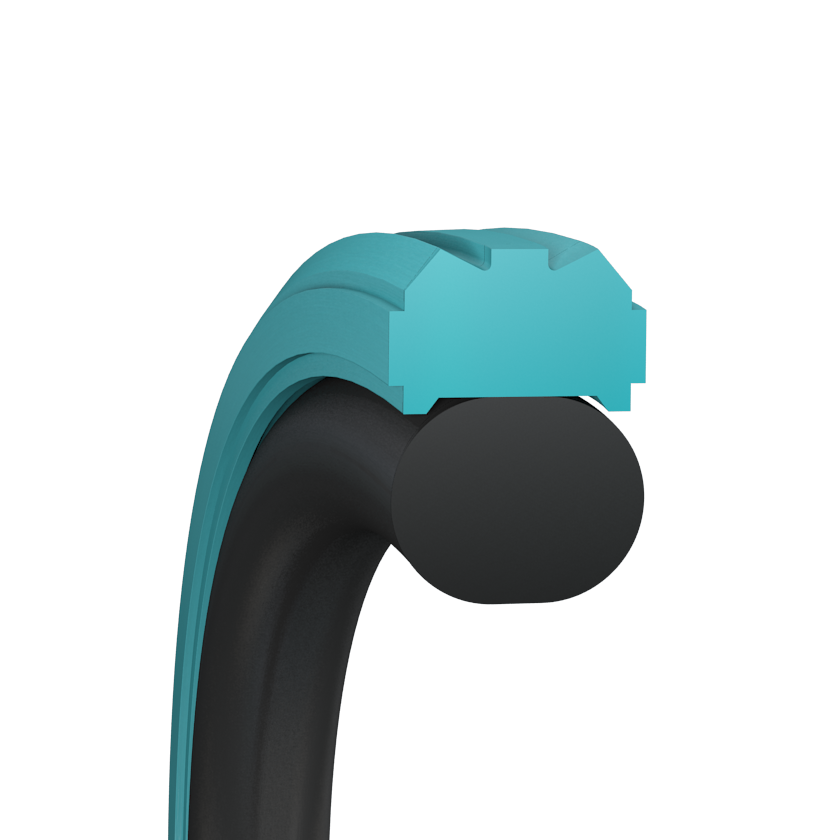

FEP Encapsulated O-Rings are coated with a sleeve of FEP which protected from chemical attack. The core is generally Viton or Silicone, which gives the o-ring the ability to recover it’s shape after it has been compressed.

Silicone cores are generally used in low temperature applications to -24°F. Viton has better compression set characteristics and is recommended in applications with constant temperature to +200°C .

FEP Encapsulated O-Rings are available in metric and imperial international standards sizes such as as AS568 , DIN ISO 3601 and JIS sizes , thus providing the quality assurance required to meet the world’s most demanding applications of O-Rings

FEP Encapsulated O-Rings Material

- Nitrile (NBR)

- Viton (FKM)

- Silicone (VMQ)

- Ethylene-propylene (EPM/EPDM)Rubbers.

- Polytetrafluoroethylene (PTFE)

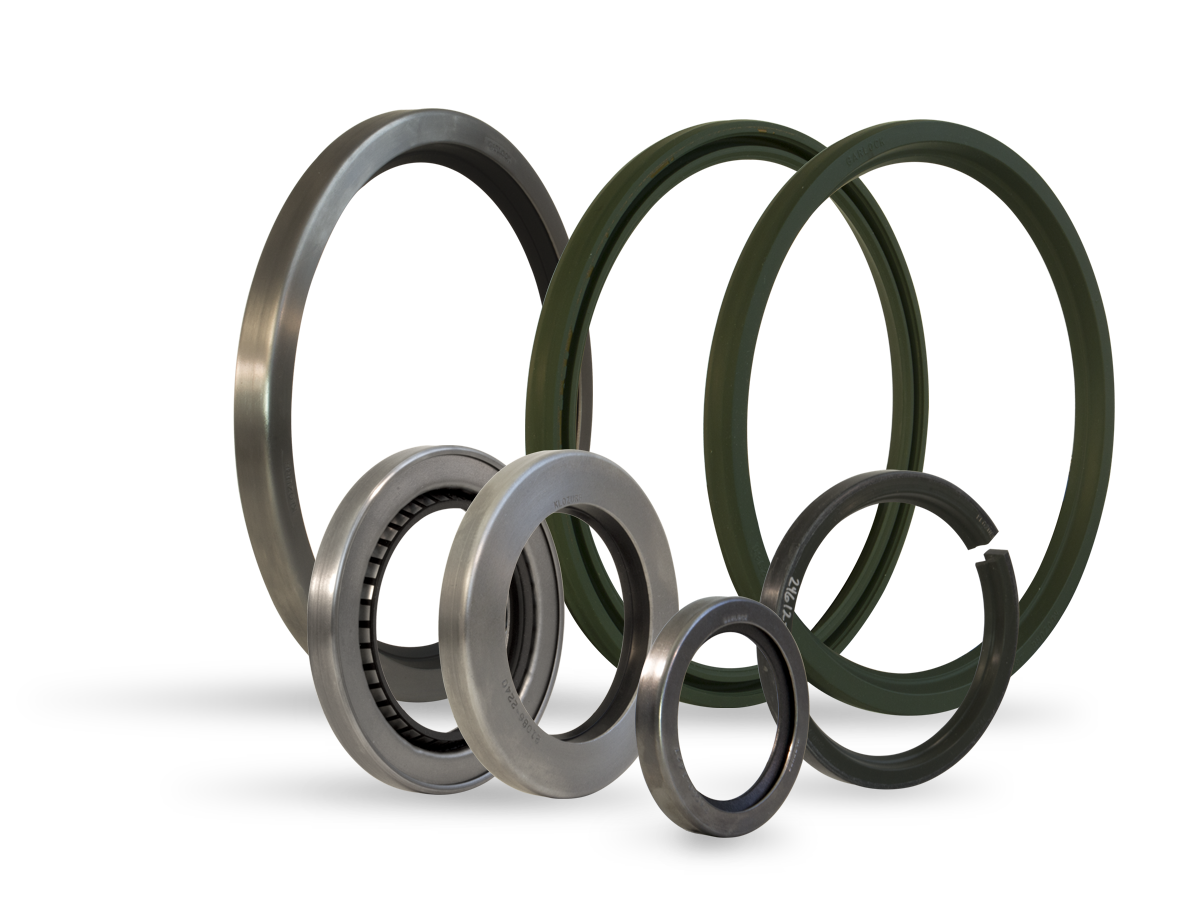

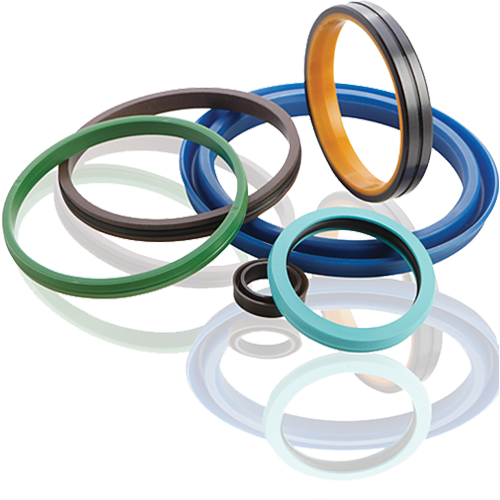

Standard O-Rings

- NBR O-Rings

- Viton O-Rings

- Silicone O-Rings

- EPDM O-Rings

- HNBR O-Rings

- PTFE O-Rings

- Fluorosilicone O-Rings

- Polyurethane O-Rings

- FEP Encapsulated O-Rings

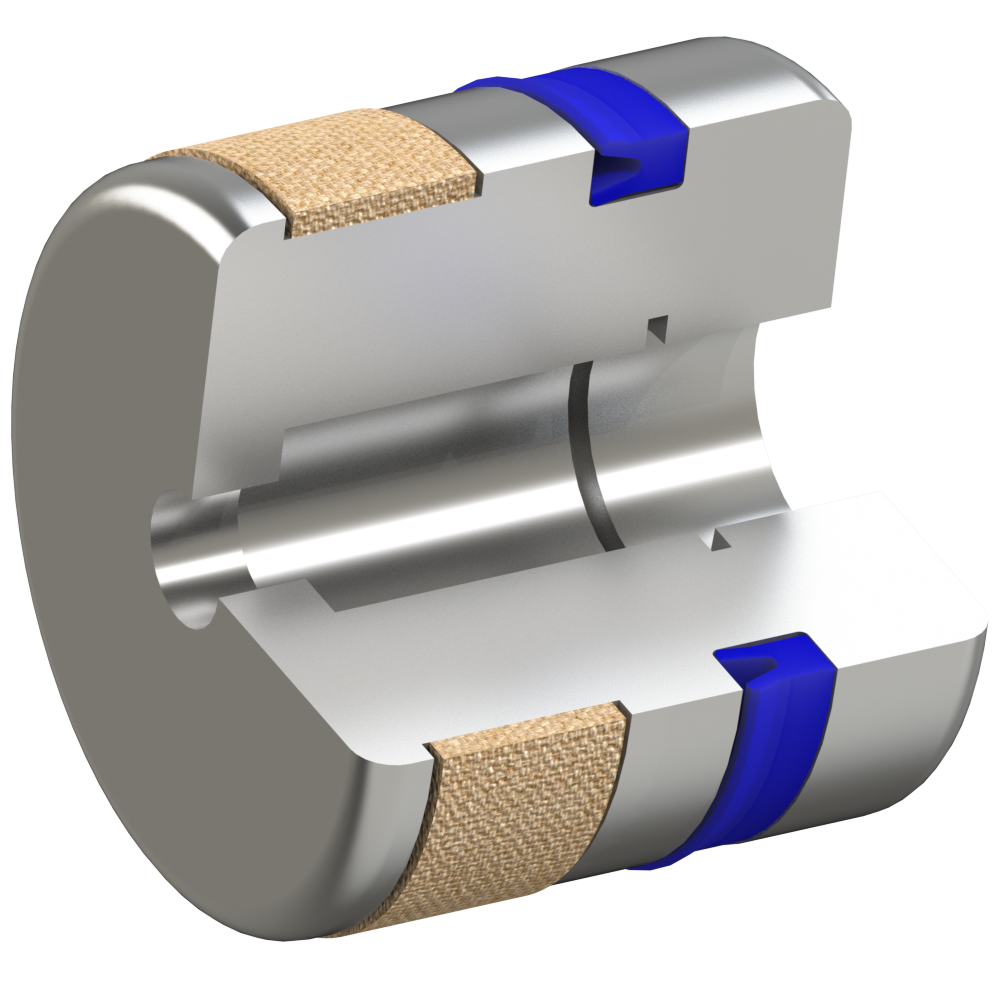

O-Rings Specifications

- O-Rings Material

- O-Rings Tolerance

- O-Rings Gland Design

- Fluid Compatibility of O-Rings Material

- O-Rings Sizes AS 568