Filter Seals

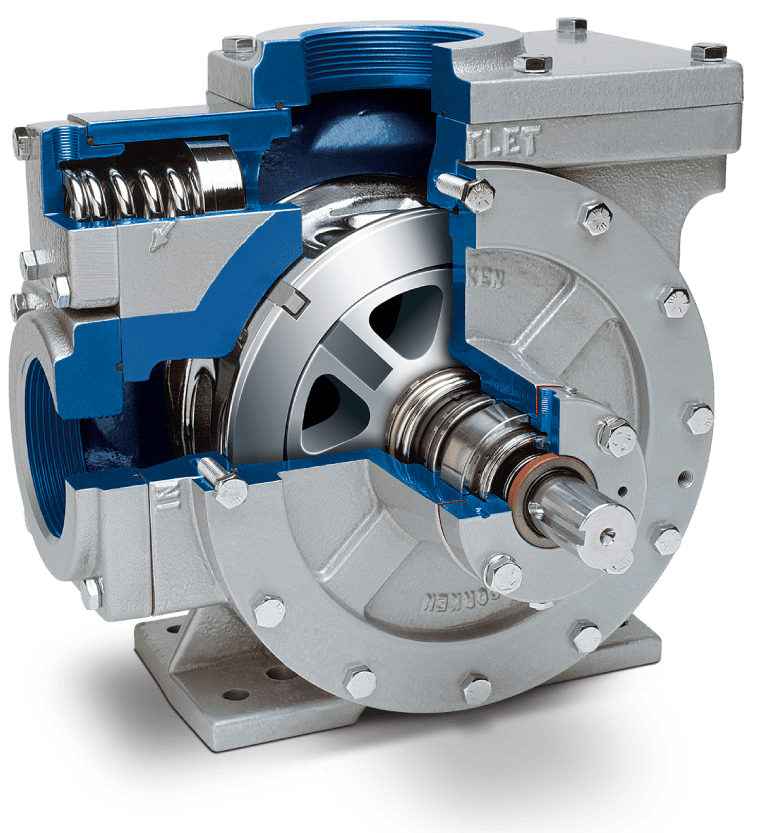

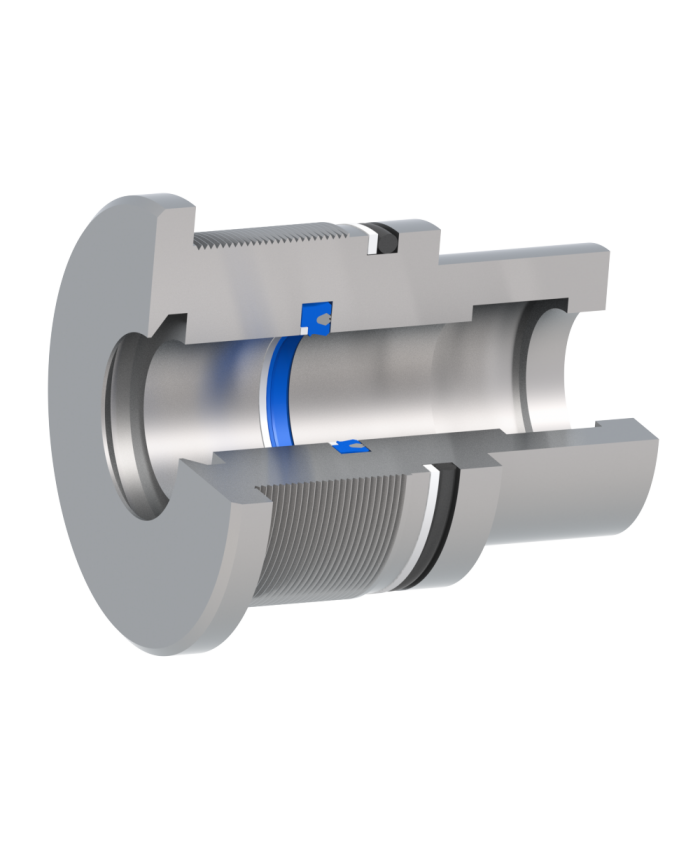

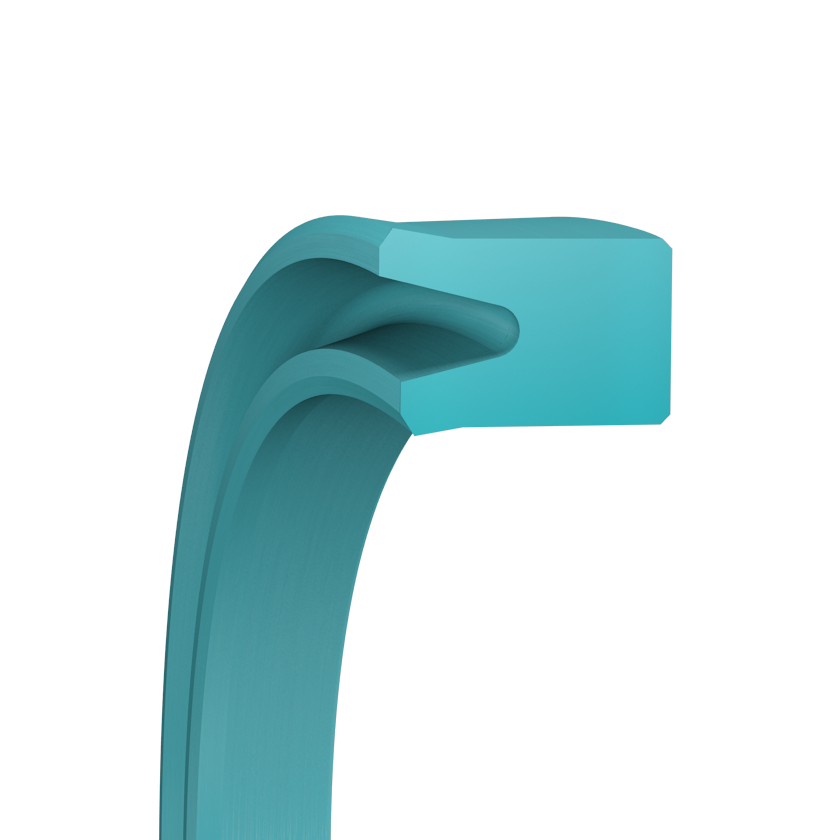

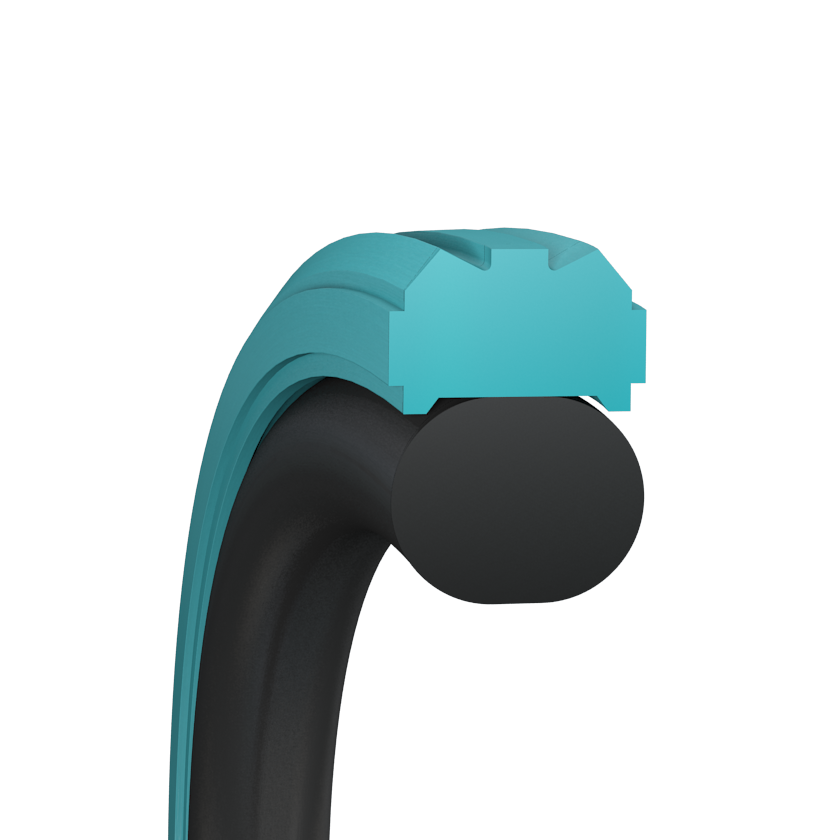

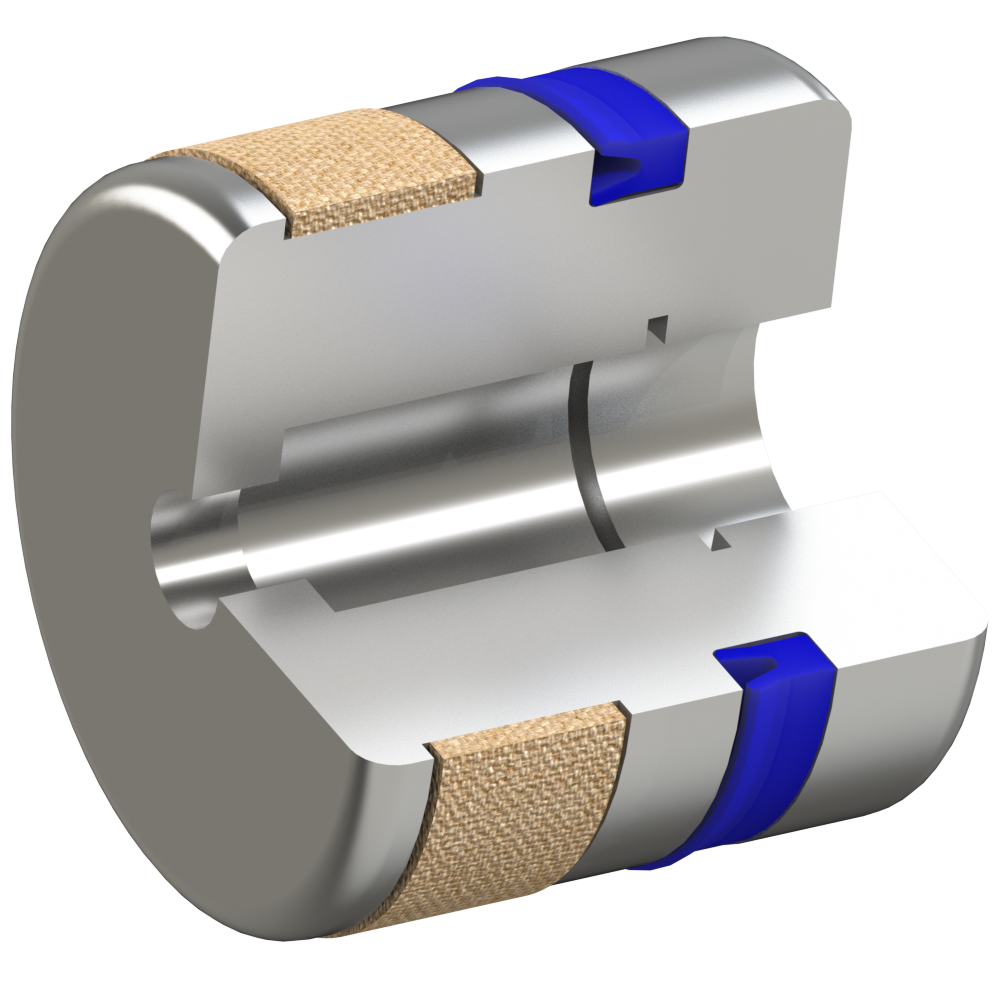

Our exclusive FilterSeal™ parts are a custom-designed combination of elastomer and fabric, metal or plastic that operates as both a seal and a filter in one device. FilterSeals™ are designed to meet your unique specifications with a variety of elastomers and filter materials available. A FilterSeal™ part can simplify your assembly process with only one component to purchase and install.

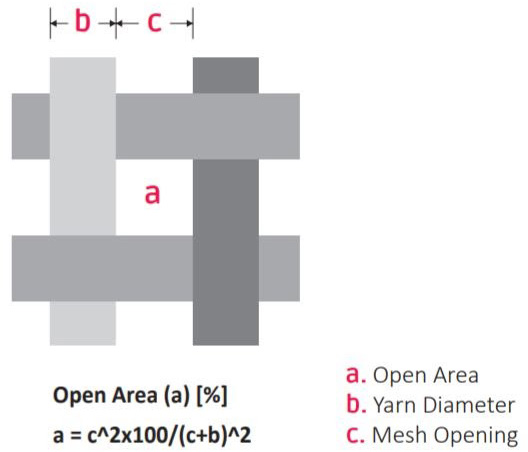

By combining a filtering mesh with rubber seal profile, a FilterSeal™ is able to perform as a high-functioning seal with filtering capabilities. These seals can be completely customizable to meet your exact needs. Simply changing the mesh material or size of the seal allows this device to filter everything from large particulates to water vapor.

Why Choose Filter Seals?

- Multi-functional: allows you to seal and filter with one part instead of two, three or more; can simplify the design of your components

- Cost and time savings: one part to purchase instead of two, one part to install, easier maintenance and replacement

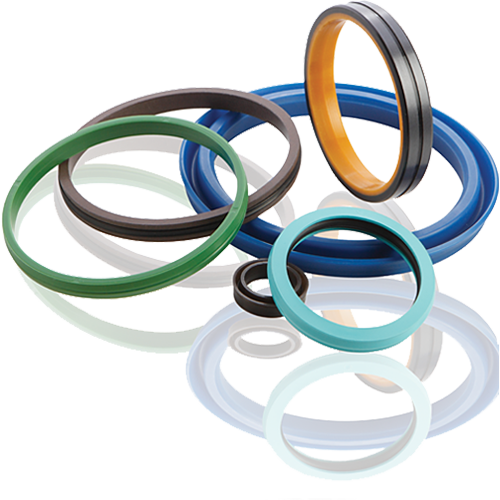

- Custom designs: Filter Seal™ is custom-designed to your exact specifications. Available in all typical elastomer materials including silicone, fluorocarbon and more, as well as a wide choice of filter materials including PTFE membrane, nylon, Dacron, etc.

- Fast turnaround: you can select an AS568 standard o-ring size and we can quickly custom manufacture a FilterSeal™ to your needs utilizing any of a variety of available fabrics.

- Unlimited applications: Diyak Rubber can design FilterSeal™ in virtually any shape or size for industries from automotive to food grade applications.

Fabric and Weave Types

- Polyester

- Plastic

- Nylon

- Stainless steel

- Fabric weave

Customize Your Material Selection

Diyak Rubber engineers can help you select the right fabric and weave based on your applications and factors such as:

- Filtration requirements

- Chemical compatibility

- Corrosion resistance

- Heat stable for molding

- Burst strength of fabric

- Flexibility of fabric

- Tensile strength

Properties of Common Plastic Mesh

| Material Properties | Unit | Nylon | Polyester | Peak |

|---|---|---|---|---|

| Tensile Strength | psi | 55k – 97k | 65k – 108k | 47k – 108k |

| Elongation at Break | % | 20 – 35 | 15 – 30 | 20 – 40 |

| Working Temperature Dry | F | 239 | 302 | 482 |

| Abrasion Resistance | good | limited | good | |

| Acid Resistance | good | limited | good | |

| Alcaline Resistance | good | limited | good | |

| Stability in Solvents | limited | good | good | |

| Hydrolysis Resistance | good | limited | good | |

| Mesh Size | µm | 1 – 5000 | 1 – 5000 | 35 – 5000 |