Hydraulic Seals: Essential Components for Reliable Sealing Solutions

Hydraulic seals play a crucial role in ensuring the efficiency, reliability, and longevity of hydraulic systems. These seals are specifically designed to prevent fluid leakage, withstand extreme pressure, and enhance the overall performance of hydraulic machinery. At Rubber Seals and Gaskets, we provide high-quality hydraulic seals that cater to diverse industrial applications.

In this blog, we will explore the types, functions, benefits, and applications of hydraulic seals to help you make informed decisions when selecting the best sealing solutions for your hydraulic systems.

What is a Hydraulic Seal?

A hydraulic seal is a component used in hydraulic cylinders and systems to prevent fluid leakage and maintain pressure within the system. These seals are essential for optimizing the performance of hydraulic equipment by minimizing wear and ensuring a smooth operation.

Hydraulic seals are made from high-performance materials such as rubber, polyurethane, PTFE, and elastomers, which are chosen based on specific operating conditions such as temperature, pressure, and fluid compatibility.

Types of Hydraulic Seals

1. Rod Seals

Prevent fluid leakage from the hydraulic cylinder.

Ensure efficient piston movement.

2. Piston Seals

Create a barrier between the piston and cylinder.

Maintain hydraulic pressure during operation.

3. Wiper Seals (Scraper Seals)

Prevent dirt, dust, and contaminants from entering the system.

Enhance the lifespan of hydraulic components.

4. O-Rings and Backup Rings

Provide additional sealing support in high-pressure applications.

Offer excellent resistance to extreme temperatures and chemicals.

5. Wear Rings (Guide Rings)

Reduce friction and wear in hydraulic cylinders.

Ensure smooth and stable motion of the piston and rod.

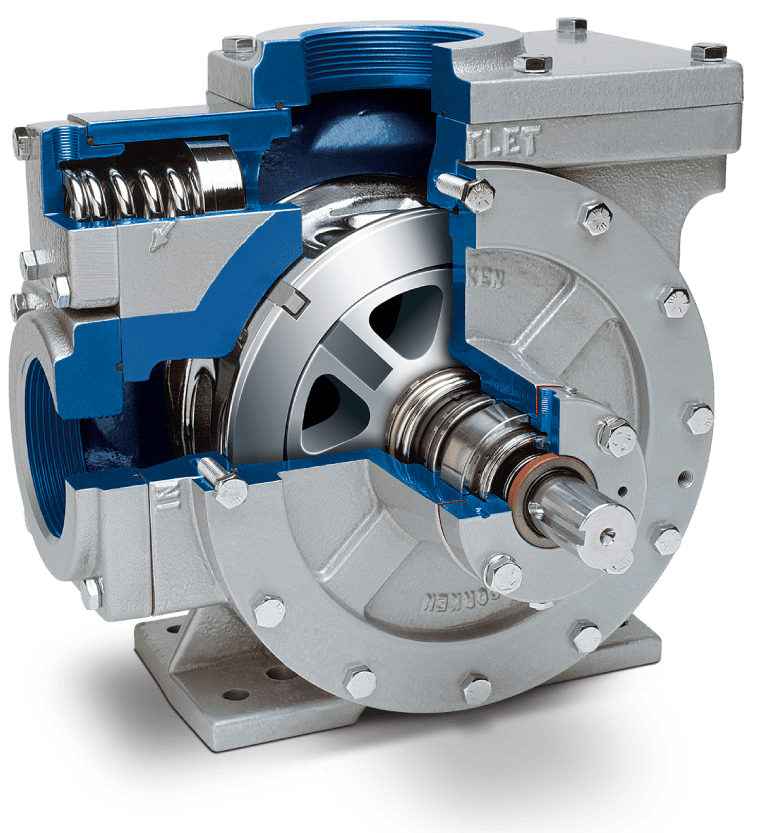

6. Rotary Seals

Used in rotating applications such as hydraulic pumps and motors.

Prevent leakage while allowing rotational movement.

Key Benefits of Hydraulic Seals

1. Superior Leak Prevention

Hydraulic seals effectively prevent fluid leakage, reducing downtime and maintenance costs.

2. Enhanced System Efficiency

By maintaining hydraulic pressure, seals improve the overall efficiency of machinery.

3. Resistance to High Pressure and Temperature

Hydraulic seals are designed to withstand extreme operating conditions, ensuring long-term durability.

4. Reduced Wear and Tear

Proper sealing minimizes friction, extending the life of hydraulic components.

5. Improved Contaminant Protection

Wiper seals prevent the entry of dust, debris, and moisture, keeping hydraulic systems clean and efficient.

Applications of Hydraulic Seals

Hydraulic seals are used across various industries due to their ability to enhance machinery performance and reliability. Some common applications include:

1. Construction and Heavy Machinery

Excavators, bulldozers, and loaders rely on hydraulic seals for smooth operation.

2. Automotive Industry

Used in hydraulic braking systems, shock absorbers, and power steering units.

3. Aerospace and Aviation

Hydraulic seals play a critical role in aircraft landing gear and hydraulic actuators.

4. Oil and Gas Industry

Essential for hydraulic drilling equipment and pressure control systems.

5. Industrial Manufacturing

Found in hydraulic presses, injection molding machines, and automated production lines.

6. Marine and Offshore Applications

Used in ship steering mechanisms, cranes, and winches.

Factors to Consider When Choosing Hydraulic Seals

To ensure optimal performance, it is important to consider the following factors when selecting hydraulic seals:

1. Material Compatibility

Choose the right material based on the type of fluid used in the hydraulic system.

Common materials include Nitrile Rubber (NBR), Polyurethane (PU), and Fluorocarbon (FKM).

2. Operating Temperature

Ensure the seal material can withstand high or low temperatures without degrading.

3. Pressure Ratings

Select seals that can handle the required hydraulic pressure without failure.

4. Seal Design and Fit

Proper dimensions and design ensure a secure fit and effective sealing.

5. Environmental Conditions

Consider exposure to chemicals, UV radiation, and abrasive contaminants when selecting hydraulic seals.

Why Choose Rubber Seals and Gaskets for Hydraulic Seals?

At Rubber Seals and Gaskets, we are committed to providing high-quality hydraulic sealing solutions tailored to various industrial needs. Here’s why our customers trust us:

✔ Premium-Grade Materials – Our hydraulic seals are made from durable, high-performance rubber and elastomers. ✔ Custom Sealing Solutions – We offer custom-designed seals to meet unique application requirements. ✔ Advanced Manufacturing Technology – Our seals are engineered with precision and strict quality control. ✔ Industry Expertise – We have years of experience in delivering reliable sealing products. ✔ Competitive Pricing and Fast Delivery – Get the best products at cost-effective prices with prompt delivery.

Conclusion

Hydraulic seals are an integral part of hydraulic systems, ensuring leak-proof operation, efficiency, and longevity. Whether in construction, automotive, aerospace, or industrial applications, selecting the right hydraulic seals enhances the performance and reliability of your machinery.

At Rubber Seals and Gaskets, we offer top-quality hydraulic seals tailored to your needs. Contact us today to find the perfect sealing solution for your industry!

FAQs

Hydraulic seals are commonly made from rubber, polyurethane, PTFE, and elastomers.

Consider material compatibility, temperature range, pressure ratings, and application requirements.

Yes, hydraulic seals are designed to withstand high-pressure environments in industrial applications.

Yes! At Rubber Seals and Gaskets, we provide custom-designed hydraulic seals to meet specific industry needs.

Upgrade your hydraulic system with premium-quality hydraulic seals from Rubber Seals and Gaskets! Get in touch today for expert sealing solutions.