Laser Marking

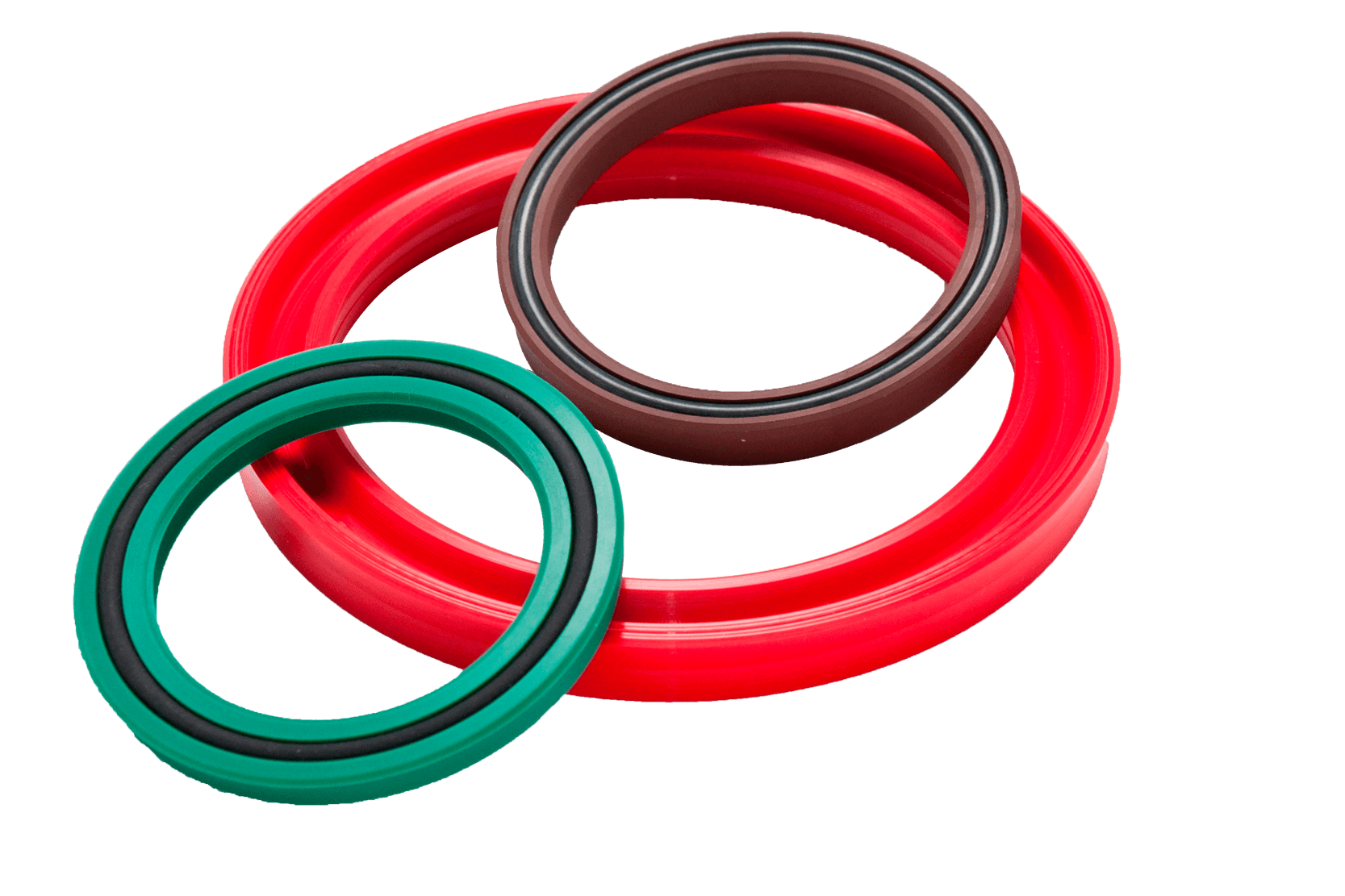

More and more manufacturers require permanent identification marks on their parts to aid in traceability. Laser marking makes it easy for companies to identify parts and lets customers know they are receiving the authentic, high-quality parts their applications demand.

Diyak Rubber’s Diyak LaserMark program uses the Samurai UV Laser Marking System, allowing us to offer high-quality identification without the use of inks or abrasions.

What is Diyak LaserMark?

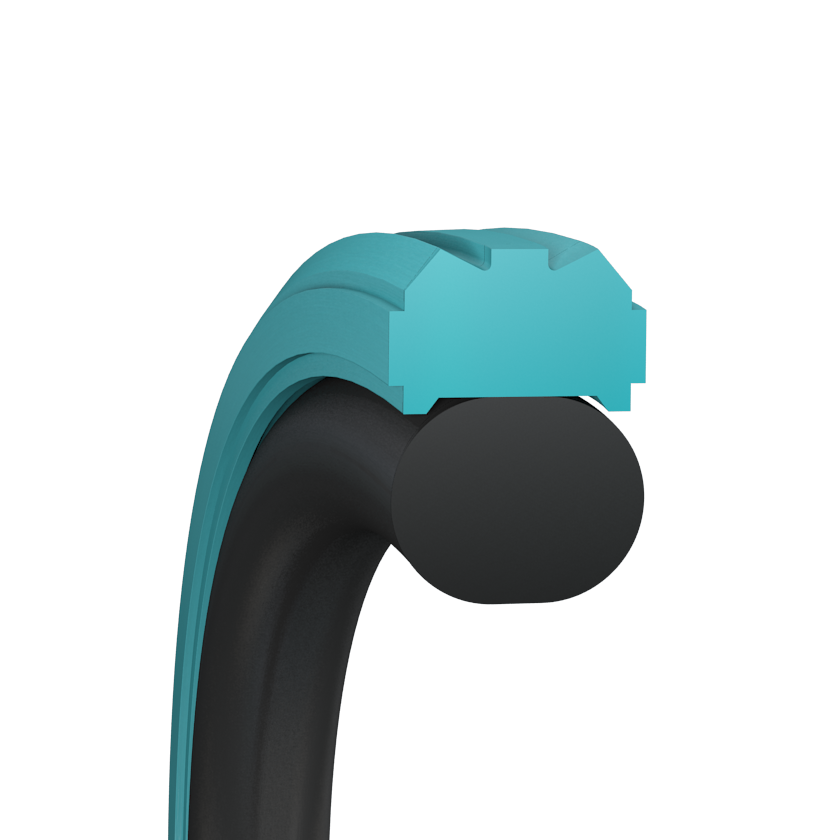

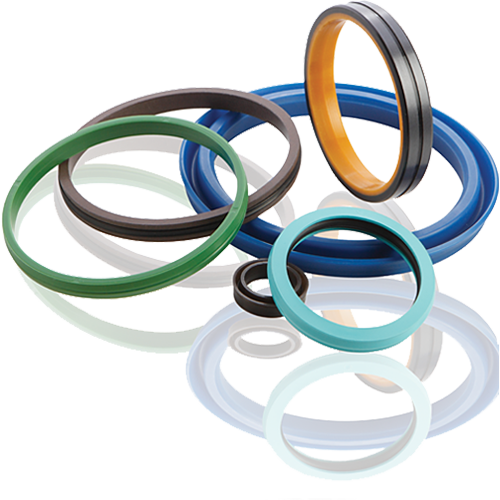

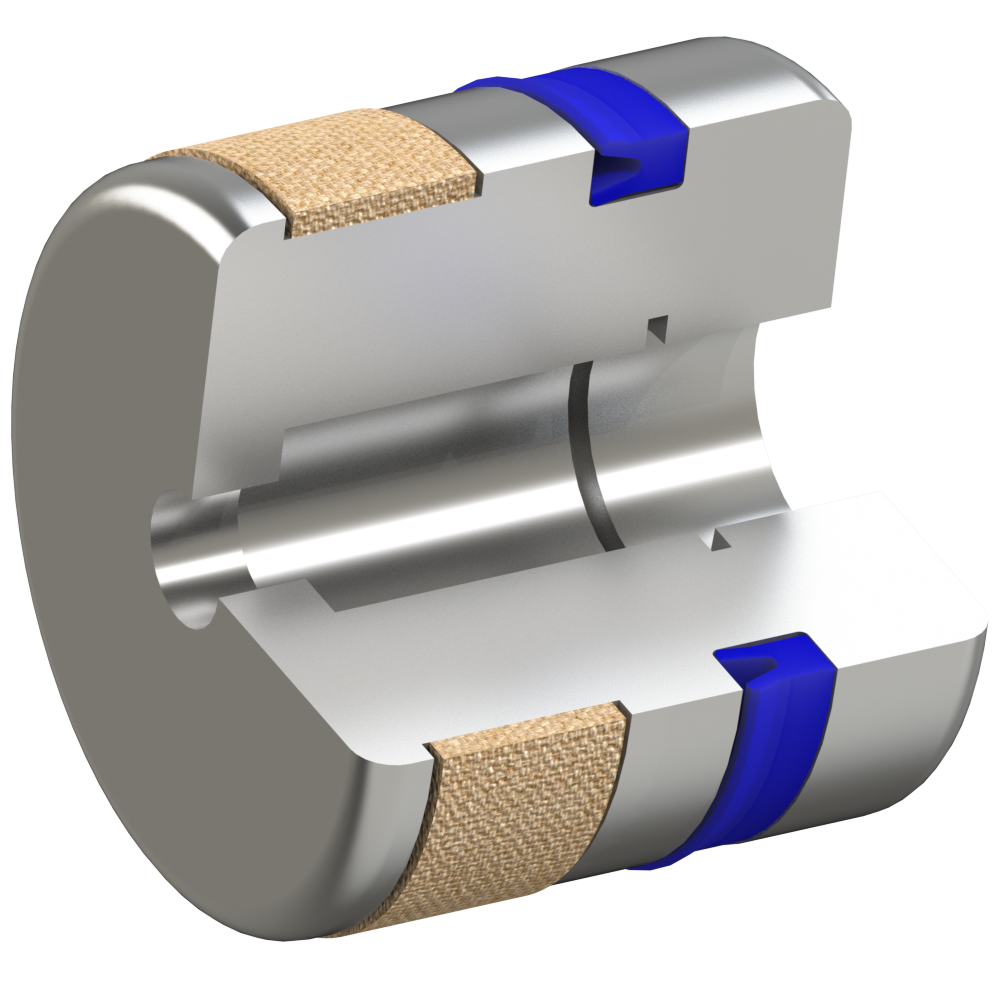

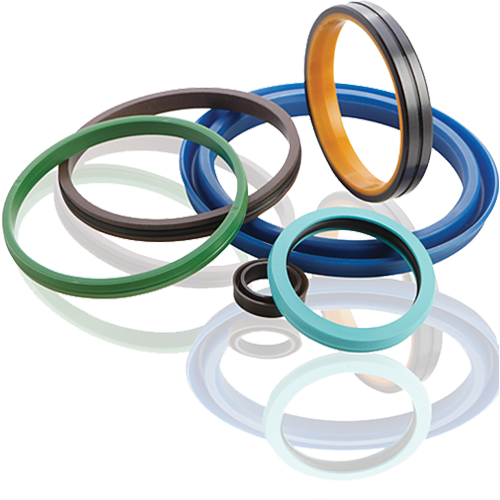

Diyak LaserMark adds model numbers, bar codes, logos and more onto our customer’s o-rings and seals.

The process does not involve a physical tool etching the surface of the part, nor does it transmit ink or any other substance onto the surface — instead, the laser light is focused onto a material, producing damage-free, easy-to-read marks.

Why choose Diyak LaserMark?

- Superior beam quality: The quality of the Samurai beam leads to a smaller spot size of the laser which, along with short pulses, produces high peak power – that means crisp, clear marks and small characters on your o-rings and seals every time

- Complete visibility: Diyak LaserMark’s easy-to-read printing is far superior to a printed mark or, even worse, a sticker

- Speed: Laser engraving is fast and simple

- Reduced maintenance: Avoid downtime associated with cleaning (or fixing) a printer

- Flexibility: Diyak LaserMark works on a variety of o-rings and sealing materials

- Minimal contamination: DiyakLaserMark ensures clean processing with minimal contamination

Laser Marking In the Field

Industries that have/are implementing global marking standards:

- Industry

- Aerospace

- Automotive

- Defense DOD

- Electronic components

- Medical devices