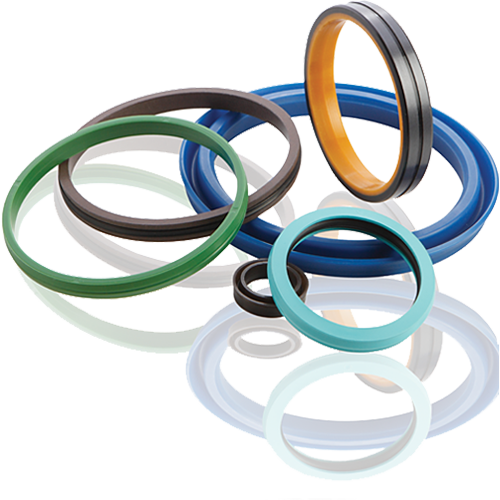

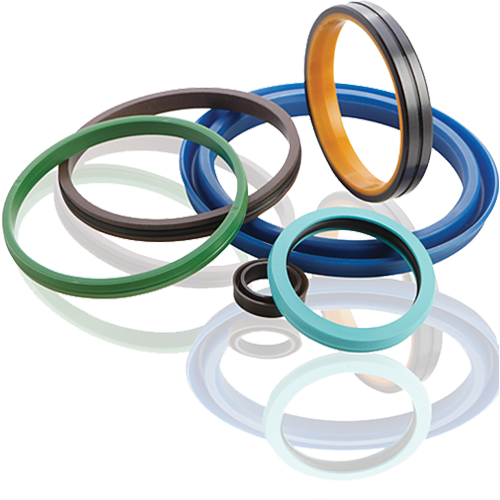

MacrOring Seals

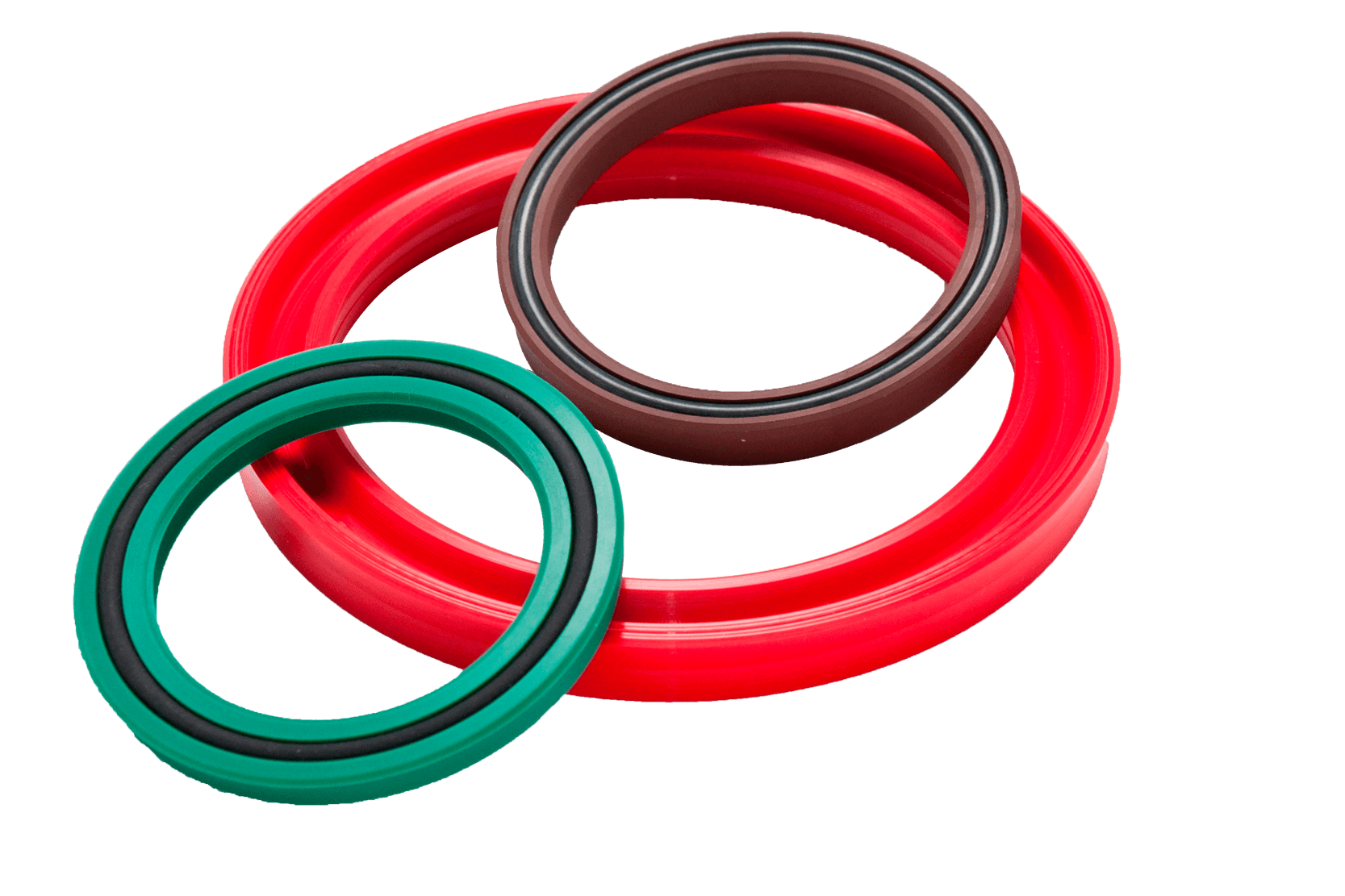

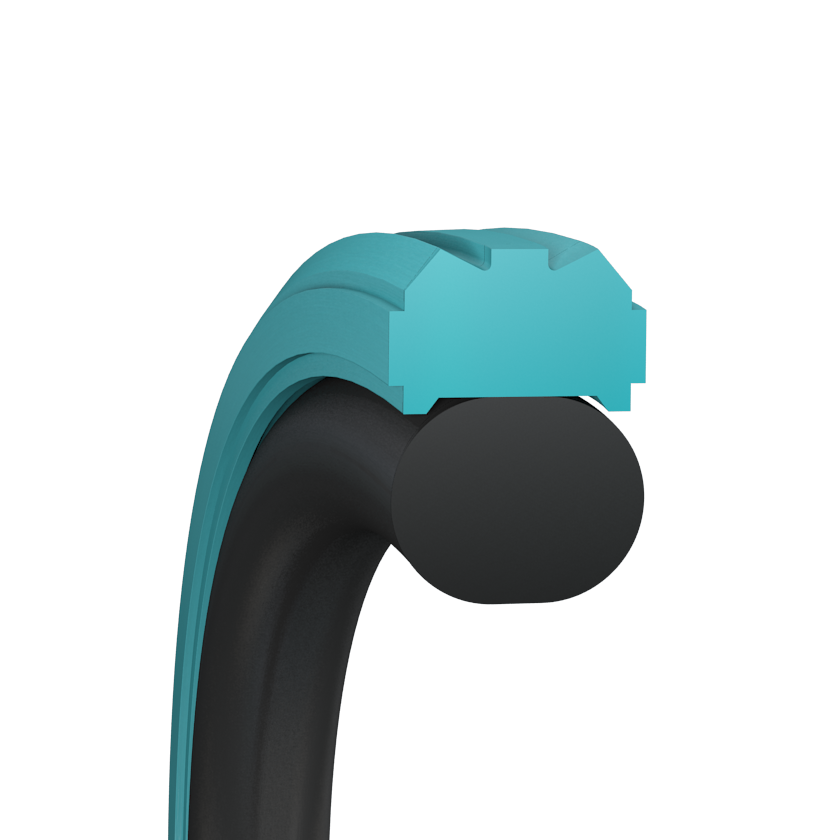

Whether you currently use molded large o-rings, seals produced by conventional bonding methods, or are undecided as to which seal is best for your application, Diyak Rubber’s MacrOring® seals are the economical, superior choice. Developed in response to growing market demands, MacrOring® seals are stronger, larger o-rings with tighter tolerances than ordinary slash and glue seals.

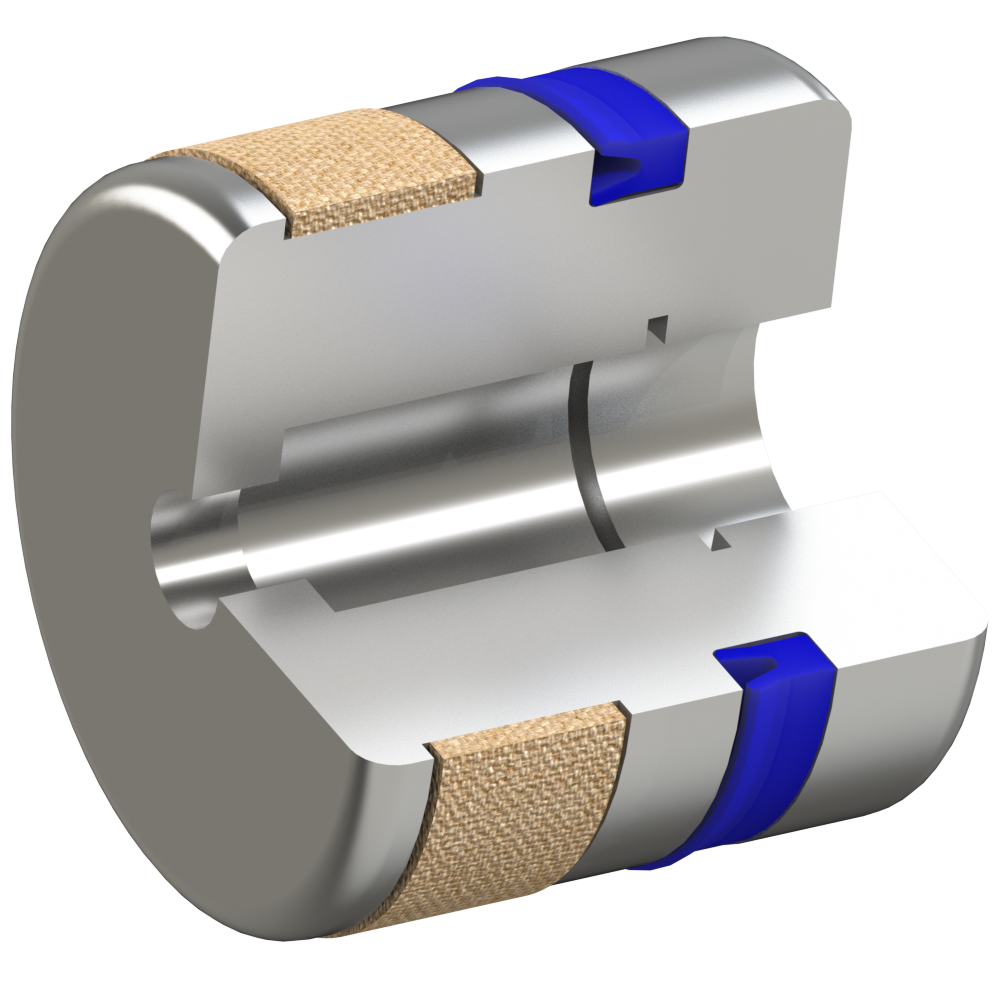

What are MacrOring® seals?

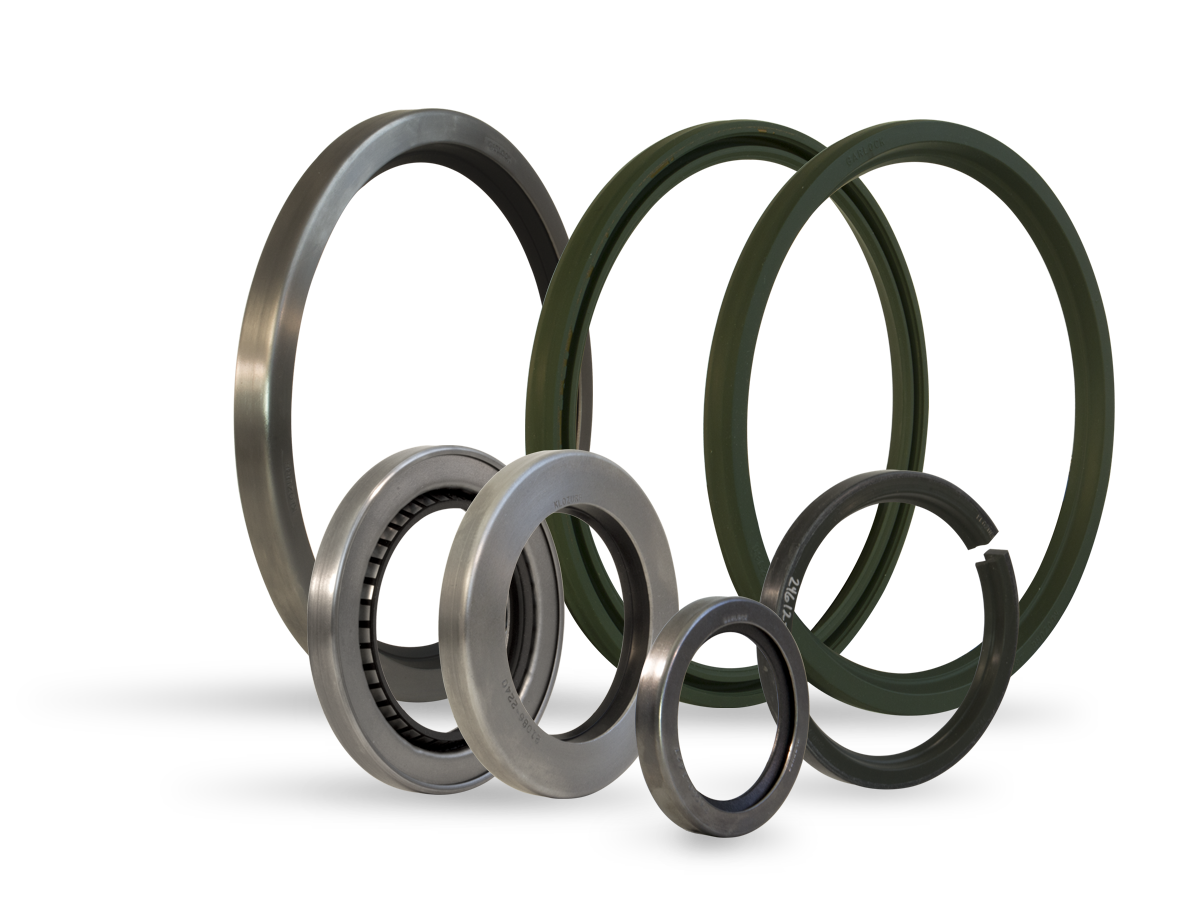

MacrOring® seals are the product of Thermobonding, DiyakRubber’s breakthrough manufacturing process for large o-rings and seals. MacrOring® seals are available from 2″ I.D. to 500″ I.D. and beyond, and in cross sections ranging from .070″ to 1″. Custom engineered seals are also available to meet your specifications, with prototypes and samples produced within 24 hours.

The Quality You Count On

- FTIR testing for material consistency

- Incoming cord material certification

- Tensile strength and other custom tests that your application may require

Cutting Down Costs

MacrOring® seals are your cost-effective solution in large or small production runs. Automatic cutting and measuring equipment results in higher production efficiencies and lower labor costs than other methods. Thermobonding also results in lower costs than traditionally molded seals by eliminating costly tooling and material waste. MacrOring® seals can be produced on demand for fast response to avoid delivery problems and production delays.

Dimensional Tolerance

| I.D. RANGE (in.) | TOLERANCE (in.) |

|---|---|

| 1.17 – 1.90 | =±.020 |

| 1.91 – 3.08 | =±.025 |

| 3.09 – 3.99 | =±.031 |

| 4.00 – 5.99 | =±.039 |

| 6.00 – 7.99 | =±.050 |

| 8.00 – 10.99 | =±.063 |

| 11.00 – 16.99 | =±.079 |

| 17.00 – 21.99 | =±.100 |

| 22.00 – 26.00 | =±.125 |

| 27.00 – 28.99 | =±.140 |

| 29.00 and over | To find the dimensional tolerance multiply by 0.6% |

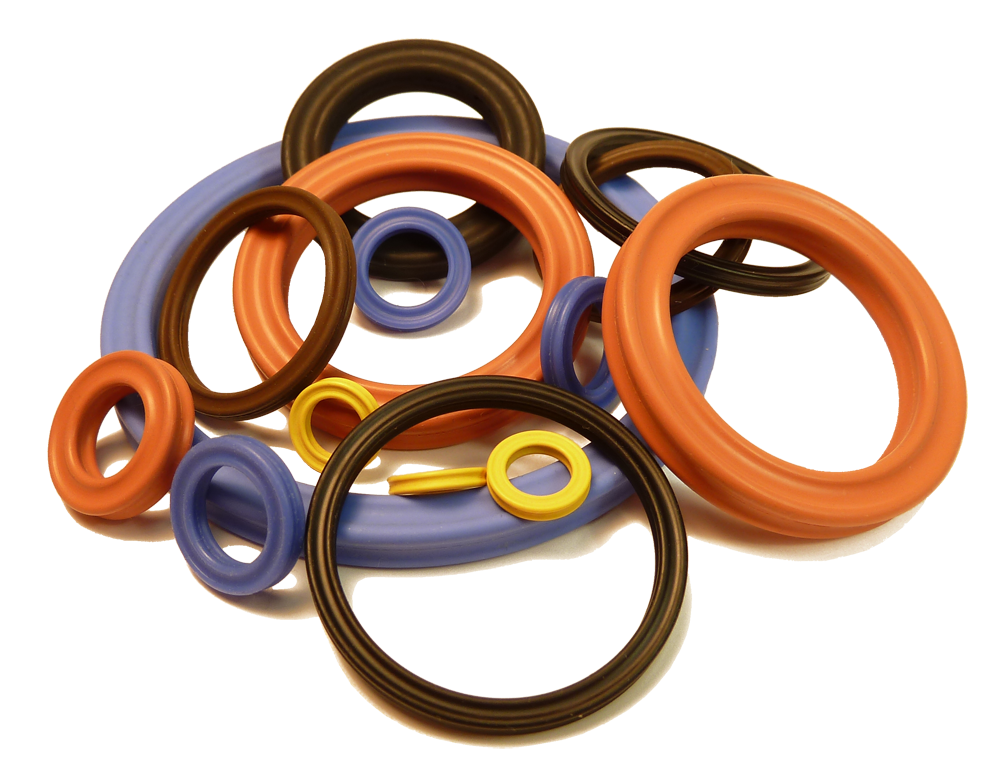

Available Materials

- Silicone

- Nitrile

- Neoprene

- Fluorosilicone

- Viton® (Fluorocarbon)

- Neoprene Sponge