ELECTRICAL & SEMICONDUCTOR INDUSTRY

-

2” to 4” Wafer Vacuum Tip – PEEK

- Spec: Apply to 2" (50mm) to 4" (100mm) With knife edge Material: PEEK - 260°C Continuous Using PolyEtherEtherKetone (PEEK) Maintains wear resistance and mechanical strength up to 260℃ continuous use. PEEK is the performance material of choice for aggressive environments such as high temperatures, wet processes, and heavy loads. It combines exceptional wear, chemical and moisture resistance with very high…

-

2” to 4” Wafer Vacuum Tip – Polyimide

- Spec: Apply to 2" (50mm) to 4" (100mm) With Knife edge Material: Polyimide - 360°C Continuous Using Special properties of Polyimide (PI) Long-term thermal stability 300 °C (short-term up to 400 °C) Good cryogenic properties down to -270 °C High strength, modulus and stiffness also at high temperatures over 260 °C Excellent wear resistance under high surface pressure and high…

-

High Temperature Pick Up Tool

- High temperature plastic pick up tool is a precision component specially used to absorb and place electronic components such as chips. It improves the indentation caused by the high hardness of the tungsten steel tip when sucking the LED chips, improves the yield rate of semiconductor packaging.

-

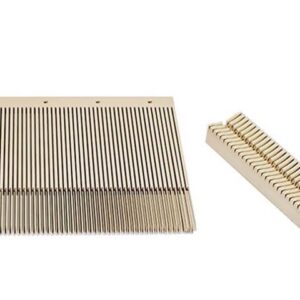

PEEK COMB WAFER RETAINER

- PolyEtherEtherKetone (PEEK) Maintains wear resistance and mechanical strength up to 260℃ continuous use. PEEK is the performance material of choice for aggressive environments such as high temperatures, wet processes, and heavy loads. It combines exceptional wear, chemical and moisture resistance with very high strength, dimensional stability and stiffness. PEEK can be continuously exposed to hot water or steam with no…

-

PEEK COMB WAFER SUPPORT

- PolyEtherEtherKetone (PEEK) Maintains wear resistance and mechanical strength up to 260℃ continuous use. PEEK is the performance material of choice for aggressive environments such as high temperatures, wet processes, and heavy loads. It combines exceptional wear, chemical and moisture resistance with very high strength, dimensional stability and stiffness. PEEK can be continuously exposed to hot water or steam with no…

-

PEEK Flat Head Phillips Screw

- PEEK Flat Head Phillips Screw

-

PEEK Hex Socket Head Cap Screws

- PEEK Hex Socket Head Cap Screws

-

PEEK Pan Head Phillips Screw

- PEEK Pan Head Phillips Screw

-

PEEK Pan Head Slotted Screw

- PEEK Pan Head Slotted Screw

-

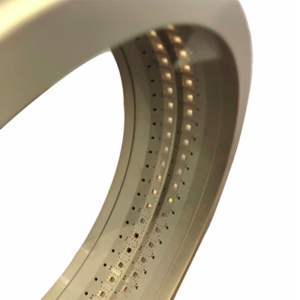

PEEK Plating Fixture

- Polyetheretherketone - Natural (beige), black Properties Superior wear resistance and dimensional stability to 260℃ continuous use Excellent resistance to chemicals, steam and hydrolysis Very low moisture absorption Very high thermal stability (V-O UL 94 rating) Superb flexural and torsional strength Abrasion resistant Good dielectric properties Good resistance to radiation Self-extinguishing

-

PEEK VACUUM PAD

- • PEEK vacuum pad for gentle and mark-free gripping and depositing of smooth workpieces • Application with crystalline solar cells, thin-film modules and wafers / substrates in the semiconductor industry • Handling of glass such as display glass, thin glass or coated glass without leaving a chemical fingerprint by elastomers

-

POLYIMIDE COMPONENTS FOR SEMICONDUCTOR AND LCD INDUSTRY

- Special properties of Polyimide (PI) Long-term thermal stability 300 °C (short-term up to 400 °C) Good cryogenic properties down to -270 °C High strength, modulus and stiffness also at high temperatures over 260 °C Excellent wear resistance under high surface pressure and high sliding speeds Excellent thermal and electrical insulation Minimal thermal conductivity High purity, low outgassing in vacuum conditions…

End of Products

No more pages to load