Description

| Carbon Steel: | Gasket | Stainless Steel: | Seal |

| Metal: | Seals Ring | Soft Iron: | Gasket |

High Light: BX157 seal ring gasket, HB160 o ring gaskets, BX157 metal seal ring

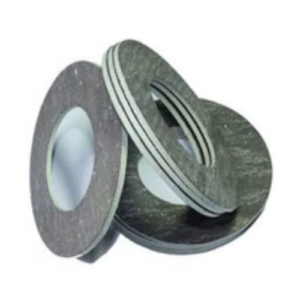

We Manufacture and supply high quality Ring joint Gaskets for high pressure and temperature service conditions. These gaskets are widely used in Refineries, Petrochemical Industries, Oil drilling well head equipments, Pressure Vessels, valves, Christmas Tree valves and Pipe lines. Ring joints Gasket are strictly manufactured as per API-6A and ASME B16.20 specification.

These include all popular sizes of “R”, “RX”, and “BX” style gaskets. Dan-Loc Group stocked gaskets include Low Carbon Steel, F5, 304, and 316 materials.

The BX type RTJ gaskets are manufactured in accordance with API 6A and are suitable for use in high pressure API 6BX flanges. The gaskets form a metal to metal seal on assembly and the efficiency improves as internal pressure increases. All BX sizes have a pressure relief hole to equalize pressure across sealing faces.

Type BX

Size Range :Available from Ring No. BX150 to RX 162 to suit the following flange specifications:

The API 6A ring gaskets for 6B flanges would be the R & RX type, and for 6BX flanges, gaskets would be the BX types.

–NB1 11/16″ to 21 1/4″ Class Rating 5000 to 20000 ASME B16.20

» BX Ring gasket Suitable for use on API 6BX Flanges up to Class 20000

» During installation the ring is compressed inwards to provide

additional sealing stress

» Pressure energised; as the internal pressure increases the

sealing force increases

» Type BX rings are supplied with pressure relief holes to avoid

compressing fluid beneath the gasket

» Can be drilled with additional hole to create a gasket suitable

for subsea installation Type “SBX”

As a result of metal to metal sealing media they are made to be free of indentations, tool marks etc and have a surface finish of maximum,

BX – 32 microinches Ra (0.8 micrometer Ra)

Type BX operates in 20,000 psi with non interchangeability. Type BX has a pressure passage hole for pressure equalization on each sealing face sides.

The hardness of the ring gasket should always be 30% lesser than the hardness of the flanges to prevent flange deformation

Dimensions and Tolerances for Ring Joint Gaskets and Grooves are covered in API 6A and ASME B16.20.

Ring type joint gaskets(RTJs) are designed for high pressure applications. They are available in a variety of forms to suit different flange formats . RTJs can be used for very high and/or fluctuating pressures (up to 1500 bar), depending on the profile selected. Material selection determines use for high temperatures (up to i000°C) and in aggressive media. To ensure proper sealing the surfaces of contact between the gaskets and flange have to be carefully processed. The small sealing area and high contact pressure results in excellent sealability.

| Common Materials | |||

| Material | HB Hardness | Temperature Limitations | Identification |

| Soft Iron | 90 | -60 to +400 °C | D |

| Low carbon steel | 120 | -40 to +500°C | S |

| 4%-6% Cr ½% Mo:F5 | 130 | -125 to +500°C | F5 |

| Stainless steel 304/304L | 160 | -250 to +650°C | S304 or 304L |

| Stainless steel 316/316L | 160 | -196 to +800°C | S316 or 316L |

| Stainless steel 321 | 160 | -250 to +870°C | S321 |

| Stainless steel 347 | 160 | -250 to +870°C | S347 |

| Stainless steel 410 | 170 | -20 to +500°C | S410 |

| Inconel 625 | – | 1000°C | 625 |

| Incoloy 825 | – | 1000°C | 825 |

| Hastelloy C-276 | – | 1000°C | C-276 |

| Duplex | – | 800°C | S31803 |

| Titanium | – | 540°C | TI |

Designs are also available for Subsea applications.

| RING NO. | PRESSLURE ALASSES, API 6BX | OUTSIDE DIAMETER OF RING OD |

HELCHT OF RING H |

WIDTH OF RING A |

HOLE SIZE D |

GASKT | |||||

| 2000 | 3000 | 5000 | 10000 | 15000 | 20000 | ||||||

| Bx150 | – | – | – | 1 11/16 | 1 11/16 | – | 72.19 | 9.3 | 9.3 | 1.59 | 0.295 |

| Bx151 | – | – | – | 1 13/16 | 1 13/16 | 1 13/16 | 76.4 | 9.63 | 9.63 | 1.59 | 0.337 |

| Bx152 | – | – | – | 2 1/16 | 2 1/16 | 2 1/16 | 84.68 | 10.24 | 10.24 | 1.59 | 0.425 |

| Bx153 | – | – | – | 2 9/16 | 2 9/16 | 2 9/16 | 100.94 | 11.38 | 11.38 | 1.59 | 0.632 |

| Bx154 | – | – | – | 3 1/16 | 3 1/16 | 3 1/16 | 116.84 | 12.4 | 12.4 | 1.59* | 0.875 |

| Bx155 | – | – | – | 4 1/16 | 4 1/16 | 4 1/16 | 147.96 | 14.22 | 14.22 | 1.59 | 1.22 |

| Bx156 | – | – | – | 7 1/16 | 7 1/16 | 7 1/16 | 237.92 | 18.62 | 18.62 | 3.18 | 4.14 |

| Bx157 | – | – | – | 9 | 9 | 9 | 294.46 | 20.98 | 20.98 | 3.18 | 6.55 |

| Bx158 | – | – | – | 11 | 11 | 11 | 352.04 | 23.14 | 23.14 | 3.18 | 9.6 |

| Bx159 | – | – | – | 13 5/8 | 13 5/8 | 13 5/8 | 426.72 | 25.7 | 25.7 | 3.18 | 14.41 |

| Bx160 | – | – | 13 5/8 | – | – | – | 402.59 | 23.83 | 13.74 | 3.18 | 6.75 |

| Bx161 | – | – | 16 3/4 | – | – | – | 491.41 | 28.07 | 16.21 | 3.18 | – |

| Bx162 | – | – | 16 3/4 | 16 3/4 | 16 3/4 | – | 475.49 | 14.22 | 14.22 | 1.59 | – |

| Bx163 | – | – | 18 3/4 | – | – | – | 556.16 | 30.1 | 17.37 | 3.18 | – |

| Bx164 | – | – | – | 18 3/4 | 18 3/4 | – | 570.56 | 30.1 | 24.59 | 3.18 | – |

| Bx165 | – | – | 21 1/4 | – | – | – | 624.71 | 32.03 | 18.49 | 3.18 | – |

| Bx166 | – | – | – | 21 1/4 | – | – | 640.03 | 32.03 | 26.14 | 3.18 | – |

| Bx167 | 26 3/4 | – | – | – | – | – | 759.36 | 35.87 | 13.11 | 1.59 | – |

| Bx168 | – | 26 3/4 | – | – | – | – | 765.25 | 35.87 | 16.05 | 1.59 | – |

| Bx169 | – | – | – | 5 1/8 | – | – | 173.51 | 15.85 | 12.93 | 1.59 | – |

| Bx170 | – | – | – | 6 5/8 | 6 5/8 | – | 218.03 | 14.22 | 14.22 | 1.59 | – |

| Bx171 | – | – | – | 8 9/16 | 8 9/16 | – | 267.44 | 14.22 | 14.22 | 1.59 | – |

| Bx172 | – | – | – | 11 5/32 | 11 5/32 | – | 333.07 | 14.22 | 14.22 | 1.59 | – |

| BX303 | 30 | 30 | – | – | – | – | 852.75 | 37.95 | 16.97 | 1.59 | – |