Description

| Carbon Steel: | Gasket | Stainless Steel: | Seal |

| Metal: | Seals Ring | Soft Iron: | Gasket |

High Light: SS316Ti RX Ring Joint Gasket, HB160 seal ring gasket, SS316Ti seal ring gasket

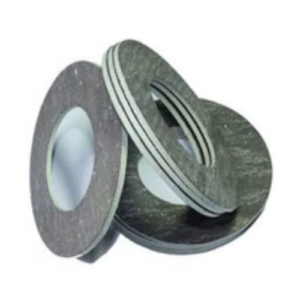

The RX type RTJ gasket is manufactured in accordance to API 6A and ASME B16.20 to suit API 6B and ASME/ANSI B16.5 flanges. The RX is a pressure energized version of the R octagonal gasket and fits the R type flat bottomed groove. The RX has an increased height and utilizes the internal system pressure to energize and improve the seal as internal pressure increases. Some RX sizes have a pressure relief hole to equalize pressure on both sides of the sealing faces.

Ring joint gaskets (RTJ Gasket) according to API 6A and ASME B16.20 for numerous industrial applications based on the customer required specifications with corrosive protection using electroplated zinc or alternate material coating of up to 0.0003” thickness.

Type RX

–NB1 1/2″ to 24″ Class Rating 720 to 5000 ASME B16.20

–NB26″ to 36″ Class Rating 300 to 900 ASME B16.20 Series A

–NB1 1/2″ to 20″ Class Rating API 6A

RX Type Gasket

Style RX type RTJ gaskets are manufactured in accordance with both API 6A and ASME B16.20 to suit API 6B and ASME/ANSI B16.5 flanges.

Style RX is a pressure-energized adaptation of the standard Style R gasket. The RX is designed to fit the same groove design as a standard Style R, making the joints interchangeable. The modified design uses a pressure-energized effect that improves the efficiency of the seal as the internal pressure of the system increases.

In order to reduce turbulent flow in adjoining flanges and prevent gasket/flange erosion Goodrich Gasket offers SPECIAL R, RX type joints with PTFE inserts. Goodrich Gasket also offers Nitrile Rubber coated ring joint gaskets (RTJ Gasket) used in pressure testing applications and as a protection for flange grooves and surfaces. Ring joint flanges with different ring groove diameters are sealed by Transition Ring joints, a different size and same PCD combination rings. Blind Ring joints, a standard ring joint with integral solid metallic centers blanks off flanges and pipe work. Flange Guards of closed cell neoprene foam readily compress under load protecting outside diameter of Ring joints in corrosive environments.

| Common Materials | |||

| Material | HB Hardness | Temperature Limitations | Identification |

| Soft Iron | 90 | -60 to +400 °C | D |

| Low carbon steel | 120 | -40 to +500°C | S |

| 4%-6% Cr ½% Mo:F5 | 130 | -125 to +500°C | F5 |

| Stainless steel 304/304L | 160 | -250 to +650°C | S304 or 304L |

| Stainless steel 316/316L | 160 | -196 to +800°C | S316 or 316L |

| Stainless steel 321 | 160 | -250 to +870°C | S321 |

| Stainless steel 347 | 160 | -250 to +870°C | S347 |

| Stainless steel 410 | 170 | -20 to +500°C | S410 |

| Inconel 625 | – | 1000°C | 625 |

| Incoloy 825 | – | 1000°C | 825 |

| Hastelloy C-276 | – | 1000°C | C-276 |

| Duplex | – | 800°C | S31803 |

| Titanium | – | 540°C | TI |

Pressure: 2,000-5,000 PSI

| RING NO. | PRESSLURE ALASSES, API 6B | PITCH DLAMETER OF RING P |

OUTSIDE DLAMETER OF RING 0D |

WIDTH OF RING A |

HELCHT OF RING H |

WEIGHT Ibs. |

|||

| 720-960and 2000[Note(1)] |

2900[Note(1)] | 3000 | 5000 | ||||||

| Rx20 | 1 1/2 | – | 1 1/2 | 1 1/2 | 68.26 | 76.2 | 8.73 | 19.05 | 0.527 |

| Rx23 | 2 | – | – | – | 82.55 | 93.27 | 11.91 | 25.4 | 1.15 |

| Rx24 | – | – | 2 | 2 | 95.25 | 105.97 | 11.91 | 25.4 | 1.33 |

| Rx25 | – | – | – | 3 1/8 | 101.6 | 109.54 | 8.73 | 19.05 | 1.42 |

| Rx26 | 2 1/2 | – | – | – | 101.6 | 111.92 | 11.91 | 25.4 | 1.5 |

| Rx27 | – | – | 2 1/2 | 2 1/2 | 107.95 | 118.27 | 11.91 | 25.4 | 1.73 |

| Rx31 | 3 | – | 3 | – | 123.83 | 134.54 | 11.91 | 25.4 | 1.91 |

| Rx35 | – | – | – | 3 | 136.53 | 147.24 | 11.91 | 25.4 | 2.09 |

| Rx37 | 4 | – | 4 | – | 149.23 | 159.94 | 11.91 | 25.4 | 2.27 |

| Rx39 | – | – | – | 4 | 161.93 | 172.64 | 11.91 | 25.4 | 2.54 |

| Rx41 | 5 | – | 5 | – | 180.98 | 191.69 | 11.91 | 25.4 | 2.72 |

| Rx44 | – | – | – | 5 | 193.68 | 204.39 | 11.91 | 25.4 | 2.96 |

| Rx45 | 6 | – | 6 | – | 211.14 | 281.85 | 11.91 | 25.4 | 3.66 |

| Rx46 | – | – | – | 6 | 211.14 | 222.25 | 13.49 | 28.58 | 8.56 |

| Rx47 | – | – | – | 8(2) | 228.6 | 245.27 | 19.84 | 41.28 | 3.79 |

| Rx49 | 8 | – | 8 | – | 269.88 | 280.59 | 11.91 | 25.4 | 5.36 |

| Rx50 | – | – | – | 8 | 269.88 | 283.37 | 16.67 | 31.75 | 4.56 |

| Rx53 | 10 | – | 10 | – | 323.85 | 334.57 | 11.91 | 25.4 | 6.45 |

| Rx54 | – | – | – | 10 | 323.85 | 337.34 | 16.67 | 31.75 | 5.36 |

| Rx57 | 12 | – | 12 | – | 381 | 391.72 | 11.91 | 25.4 | 26.4 |

| Rx63 | – | – | – | 14 | 419.1 | 441.72 | 26.99 | 50.8 | 6.63 |

| Rx65 | 16 | – | – | – | 469.9 | 480.62 | 11.91 | 25.4 | 9.39 |

| Rx66 | – | – | 16 | – | 469.9 | 483.39 | 16.67 | 31.75 | 7.52 |

| Rx69 | 18 | – | – | – | 533.4 | 544.12 | 11.91 | 25.4 | 20.14 |

| Rx70 | – | – | 18 | – | 533.4 | 550.07 | 19.84 | 41.28 | 11.63 |

| Rx73 | 20 | – | – | – | 584.2 | 596.11 | 13.49 | 31.75 | 22.1 |

| Rx74 | – | – | 20 | – | 584.2 | 600.87 | 19.84 | 41.28 | 0.79 |

| Rx82 | – | 1 | – | – | 57.15 | 67.87 | 11.91 | 25.4 | 0.88 |

| Rx84 | – | 1 1/2 | – | – | 63.5 | 74.22 | 11.91 | 25.4 | 0.88 |

| Rx85 | – | 2 | – | – | 79.38 | 90.09 | 13.49 | 25.4 | 1.79 |

| Rx86 | – | 2 1/2 | – | – | 90.49 | 103.58 | 15.08 | 28.58 | 1.98 |

| Rx87 | – | 3 | – | – | 100.03 | 113.11 | 15.08 | 28.58 | 3.22 |

| Rx88 | – | 4 | – | – | 123.83 | 139.29 | 17.46 | 31.75 | 2.98 |

| Rx89 | – | 3 1/2 | – | – | 114.3 | 129.78 | 18.26 | 31.75 | 6.82 |

| Rx90 | – | 5 | – | – | 155.58 | 174.63 | 19.84 | 44.45 | 17.1 |

| Rx91 | – | 10 | – | – | 260.35 | 286.94 | 30.18 | 45.24 | 3.31 |

| Rx99 | 8(2) | – | 8(2) | – | 234.95 | 245.67 | 11.91 | 25.4 | – |

| Rx201 | – | – | – | 1 3/8 | 46.04 | 51.46 | 5.74 | 11.3 | – |

| Rx205 | – | – | – | 1 13/16 | 57.15 | 62.31 | 5.56 | 11.1 | – |

| Rx210 | – | – | – | 2 9/16 | 88.9 | 97.63 | 9.53 | 19.05 | – |

| RX215 | – | – | – | 4 1/16 | 130.18 | 140.89 | 11.91 | 25.4 | – |