Description

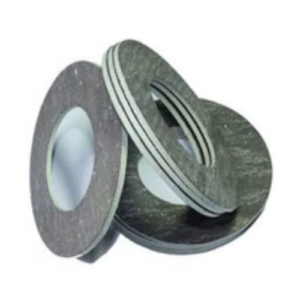

API6A RTJ GASKET Weellhead Oct Ring Joint Gasket

| Stainless Steel: | Seals Ring | Api: | Gasket |

|---|---|---|---|

| Wellhead: | Ring Joint Gasket | Raw Material: | Carbon Stell |

| Material: | Soft Iron | Standard: | API 6a |

| Industry: | Oilfield And Gas | Subsea: | Gasket |

| Carbon Steel: | Gasket |

Operating range

The pressure and temperature depend on the combination of materials used.

Chemical resistance:The corrosion resistance depends on the selected ring material.

Standards and approvals

All RTJ gaskets are manufactured to API standards, guaranteeing consistent quality.

Recommended applications

Industries

- Oil & gas industry

- Petrochemical industry

- Flange connections

- Pipe connections

Materials

RTJ gaskets are available as standard in soft metal and in 304, 316 and stainless steels. Versions in other materials on request.

Style R ring type joints are manufactured on oval (2962/R) and octagonal profiles (2961/R).

Both styles are interchangeable in the modern flat bottomed groove.

Octagonal profile joints are interchangeable on flat bottomes groove flanges which have a 23 degree angle groove wall

Advantages

- Metal-to-metal contact creates a reliable seal

- Suitable for extreme pressure and temperature requirements

- Certified quality (including surface hardness)

we supplies ring joint gaskets (RTJ Gasket) with the hardness numbers as follows:

| GASKET MATERIALS | BRINELL HARDNESS NUMBER (max) | ROCKWELL HARDNESS NUMBER (max) | IDENTIFICATION |

|---|---|---|---|

| Soft iron | 90 | 56 | D |

| Low carbon steel | 120 | 68 | S |

| 4-6% Chrome 1/2% molybdenum | 130 | 72 | F5 |

| 304 Stainless Steel | 160 | 83 | S304 |

| 316 Stainless Steel | 160 | 83 | S316 |

| 347 Stainless Steel | 160 | 83 | S347 |

| Common Materials | |||

| Material | HB Hardness | Temperature Limitations | Identification |

| Soft Iron | 90 | -60 to +400 °C | D |

| Low carbon steel | 120 | -40 to +500°C | S |

| 4%-6% Cr ½% Mo:F5 | 130 | -125 to +500°C | F5 |

| Stainless steel 304/304L | 160 | -250 to +650°C | S304 or 304L |

| Stainless steel 316/316L | 160 | -196 to +800°C | S316 or 316L |

| Stainless steel 321 | 160 | -250 to +870°C | S321 |

| Stainless steel 347 | 160 | -250 to +870°C | S347 |

| Stainless steel 410 | 170 | -20 to +500°C | S410 |

| Inconel 625 | – | 1000°C | 625 |

| Incoloy 825 | – | 1000°C | 825 |

| Hastelloy C-276 | – | 1000°C | C-276 |

| Duplex | – | 800°C | S31803 |

| Titanium | – | 540°C | TI |

We specializes in ring joint gasket, including ring gasket in R, RX, BX, IX types, lens gasket, weld ring gasket and bonnet gasket(according to client’s drawing). The metal gasket designed for use in high pressure, high temperature application necessitated the need for a high integrity seal. Our products are widely used in flat gate valve, Christmas tree, pipeline fittings, flange, high pressure vessel, oil &gas industry, wellhead assembly, petrochemical industry and the like.