Description

| Carbon Steel: | Gasket | Stainless Steel: | Seal |

| Metal: | Seals Ring | Soft Iron: | Gasket |

High Light: 300LB BX Ring Joint Gasket, ASME B16.20 o ring joints, 300LB o ring joints

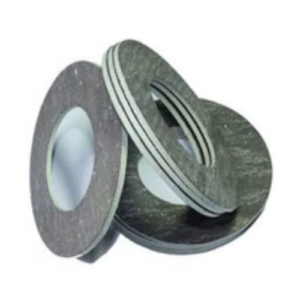

We Manufacture and supply high quality Ring joint Gaskets for high pressure and temperature service conditions. These gaskets are widely used in Refineries, Petrochemical Industries, Oil drilling well head equipments, Pressure Vessels, valves, Christmas Tree valves and Pipe lines. Ring joints Gasket are strictly manufactured as per API-6A and ASME B16.20 specification.

The BX type RTJ gaskets are manufactured in accordance with API 6A and are suitable for use in high pressure API 6BX flanges. The gaskets form a metal to metal seal on assembly and the efficiency improves as internal pressure increases. All BX sizes have a pressure relief hole to equalize pressure across sealing faces.

Type BX

–NB1 11/16″ to 21 1/4″ Class Rating 5000 to 20000 ASME B16.20

» BX Ring gasket Suitable for use on API 6BX Flanges up to Class 20000

» During installation the ring is compressed inwards to provide

additional sealing stress

» Pressure energised; as the internal pressure increases the

sealing force increases

» Type BX rings are supplied with pressure relief holes to avoid

compressing fluid beneath the gasket

» Can be drilled with additional hole to create a gasket suitable

for subsea installation Type “SBX”

As a result of metal to metal sealing media they are made to be free of indentations, tool marks etc and have a surface finish of maximum,

BX – 32 microinches Ra (0.8 micrometer Ra)

Type BX operates in 20,000 psi with non interchangeability. Type BX has a pressure passage hole for pressure equalization on each sealing face sides.

The hardness of the ring gasket should always be 30% lesser than the hardness of the flanges to prevent flange deformation

Dimensions and Tolerances for Ring Joint Gaskets and Grooves are covered in API 6A and ASME B16.20.

Ring type joint gaskets(RTJs) are designed for high pressure applications. They are available in a variety of forms to suit different flange formats . RTJs can be used for very high and/or fluctuating pressures (up to 1500 bar), depending on the profile selected. Material selection determines use for high temperatures (up to i000°C) and in aggressive media. To ensure proper sealing the surfaces of contact between the gaskets and flange have to be carefully processed. The small sealing area and high contact pressure results in excellent sealability.

| Common Materials | |||

| Material | HB Hardness | Temperature Limitations | Identification |

| Soft Iron | 90 | -60 to +400 °C | D |

| Low carbon steel | 120 | -40 to +500°C | S |

| 4%-6% Cr ½% Mo:F5 | 130 | -125 to +500°C | F5 |

| Stainless steel 304/304L | 160 | -250 to +650°C | S304 or 304L |

| Stainless steel 316/316L | 160 | -196 to +800°C | S316 or 316L |

| Stainless steel 321 | 160 | -250 to +870°C | S321 |

| Stainless steel 347 | 160 | -250 to +870°C | S347 |

| Stainless steel 410 | 170 | -20 to +500°C | S410 |

| Inconel 625 | – | 1000°C | 625 |

| Incoloy 825 | – | 1000°C | 825 |

| Hastelloy C-276 | – | 1000°C | C-276 |

| Duplex | – | 800°C | S31803 |

| Titanium | – | 540°C | TI |

Standard Gasket Material

Carbon Steel

Commercial quality sheet steel with an upper temperature limit of approximately 1000º F., particularly if conditions are oxidizing. Not suitable for handling crude acids or aqueous solutions of salts in the neutral or acid range. A high rate of failure may be expected in hot water service if the material is highly stressed, Concentrated acids and most alkalies have little or no action on iron and steel gaskets which are used regularly for such services.

304 Stainless Steel

- An 18-8 (Chromium 18-20%, Nickel 8-10%) Stainless with a maximum recommended working temperature of 1400º F

- At least 80% of applications for non-corrosive services can use Type 304 Stainless in the temperature range of -320 F to 1000º F.

- Excellent corrosion resistance to a wide variety of chemicals.

- Subject to stress corrosion crackling and to intergranular corrosion at temperatures between 800º F to 1500º F in presence of certain media for prolonged periods of time.

316 Stainless Steel

- An18-12 Chromium-Nickel steel with approximately 2% of Molybdenum added to the straight 18-8 alloy which increases its strength at elevated temperatures and results in somewhat improved corrosion resistance.

- Has the highest creep strength at elevated temperatures of any conventional stainless type.

- Not suitable for extended service within the carbide precipitation range of 800º F to 1650º F. when corrosive conditions are severe.

- Recommended maximum working temperature of 1400º F.

316L Stainless Steel

- Continuous maximum temperature range of 1400º F -1500º F.

- Carbon content held at a maximum of .03%.

- Subject to a lesser degree of stress corrosion cracking and also to intergranular corrosion than Type 316.

321 Stainless Steel

- An 18-10 Chromium-Nickel steel with a Titanium addition.

- Type 321 stainless has the same characteristics as Type 347.

- The recommended working temperature is 1400º F to 1500º F. and in some instances 1600º F.

347 Stainless Steel

- An 18-10 Chromium-Nickel steel with the addition of Columbium.

- Not as subject to intergranular corrosion as is Type 304.

- Is subject to stress corrosion.

- Recommended working temperature of 1400º F -1500º F and in some instances to 1700º F.

410 Stainless Steel

- A 12% Chromium steel with a maximum temperature range of 1200º F. to 1300º F.

- Used for applications requiring good resistance to sealing at elevated temperatures.

- Is not recommended for use where severe corrosion in encountered but is still very useful for some chemical application.

- May be used where dampness, alone or coupled with chemical pollution, causes steel to fail quickly.

502/501(F5)

- 4-6% Chromium and 1/2% Molybdenum alloyed for mild corrosive resistance and elevated service. Maximum working temperature is 1200º F.

- If severe corrosion is anticipated, a better grade of stainless steel would probably be a better choice. Becomes extremely hard when welded.

Admiralty

- Arsenical Admiralty 443 has 71% Copper, 28% Zinc, 1% Tin and trace amounts of Arsenic.

- High corrosive resistance, holds up extremely well against salt and brackish waters, and water containing sulfides.

- Recommended maximum working temperature of 500º F.

- Ideal for carrying corrosive cooling waters at relatively high temperatures.

Alloy 20

- 45% Iron, 24% Nickel, 20% chromium, and small amounts of Molybdenum and Copper.

- Maximum temperature range of 1400º F -1500º F.

- Developed specifically for applications requiring resistance to corrosion by sulfuric acid.

- Brinell hardness is about 160.

Aluminum

- Alloy 110 is commercially pure (99% minimum).

- Its excellent resistance and workability makes it ideal for double jacketed gaskets.

- For solid gaskets, stronger alloys like 5052 and 3003 are used.

- Maximum continuous service temperature of 800º F.

Brass

- Yellow brass 268 has 66% Copper and 34% Zinc.

- Offers excellent to good corrosion resistance in moist environments, but is not suitable for such materials as acetic acid, acetylene, ammonia, and salt. Maximum recommended temperature limit of 500 F.

Copper

- Nearly pure copper with trace amounts of silver added to increase its working temperature.

- Recommended maximum continuous working temperature of 500º F.

Cupro Nickel

- Contains 69% Copper, 30% Nickel and small amounts of Manganese, Zinc and Iron.

- It is mostly used in sea water applications, where lesser resistant alloys rapidly deteriorate.

- Maximum recommended temperature limit 500º F.

Hastelloy B

- 26-30% Molybdenum, 62% Nickel and 4-6% Iron.

- Maximum temperature range of 2000º F. resistant to hot, concentrated hydrochloric acid.

- Also resists the corrosive effects of wet hydrogen chlorine gas, sulfuric and phosphoric acids and reducing salt solutions.

- Useful for high temperature strength.

Hastelloy C-276

- 16-18% Molybdenum, 13-17.5% Chromium, 3.7-5.3% Tungsten, 4.5-7% Iron and the balance is Nickel. Maximum temperature range of 2000º F.

- Very good in handling corrosives.

- High resistance to cold nitric acid of varying concentrations as well as boiling nitric acid up to 70% concentration.

- Good resistance to hydrochloric acid and sulfuric acid.

- Excellent resistance to stress corrosion cracking.

Inconel 600

- Recommended working temperatures of 2000º F. and is some instances 2150º F.

- Is a nickel base alloy containing 77% Nickel, 15% Chromium and 7% Iron, Excellent high temperature strength.

- Frequently used to overcome the problem of stress corrosion.

- Has excellent mechanical properties at the cryogenic temperature range.

Incoloy 800

- 32.5% Nickel, 46% Iron, 21% Chromium, resistant to elevated temperatures, oxidation and carburization. Recommended maximum temperature of 1600º F.