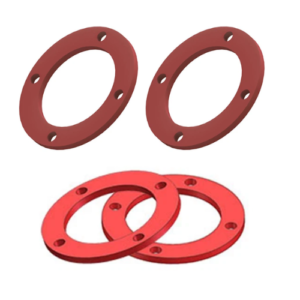

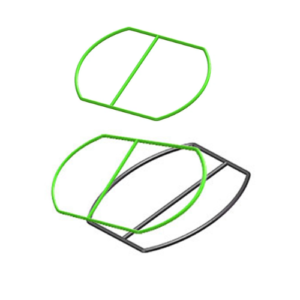

Description

Features

Excellent sealing performance: The rubber seal has good elasticity and compression deformation ability, and can closely fit the sealing surface of the ball valve to form an effective seal.

Abrasion resistance: The rubber material has good abrasion resistance, which can maintain a low wear rate and prolong the service life during the opening and closing process of the ball valve.

Corrosion resistance: Some rubber materials such as fluorine rubber have excellent corrosion resistance and can resist the erosion of a variety of chemical media.

Adaptability: The rubber seals can be customized according to the specifications and sizes of the ball valves to meet the sealing needs of different ball valves.

| Product name | Ball valve rubber seals |

| Product material | NBR, EPDM,FKM, VMQ |

| Hardness (Shore A) | 20 to 90 |

| Applicable temperature °C | -50 to 140 |

| Color | Black, orange, blue, yellow, green, custom |

| Size | Standard/ Custom |

| Advantage | Automotive industry, mechanical engineering, aerospace industry |

| Application | Petroleum, chemical industry, metallurgy, electric power, water conservancy, etc |

| Certification | ISO: 9001, ISO: 14001, IATF: 16949 |

Reviews

There are no reviews yet.