Description

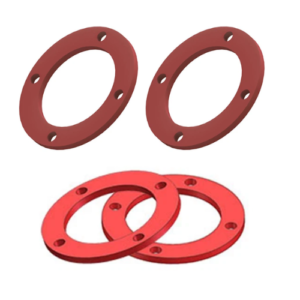

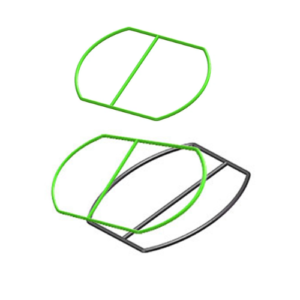

About Butterfly Valve Rubber Seals

Butterfly valve, as a key fluid control equipment, is widely used in various industrial fields. The performance and reliability of butterfly valves directly affect the safety and efficiency of the production process. As one of the key components of the butterfly valve, the butterfly valve rubber seals plays a vital role.

| Material | NBR |

| Permanent shrinkage (100℃×70h) | 7-20% |

| Hardness | 45-65 Shore A |

| Rebound rate | 5-65% |

| Elongation | ≥300-800% |

| Working temperature | -10℃~+120℃ |

Applicable working conditions

1. Temperature: Butterfly valve rubber seals are suitable for environments with a wide temperature range, such as normal temperature, high temperature, low temperature, etc. Depending on the material and formulation, seals can be used in a temperature range of -100°C to +500°C.

2. Pressure: Butterfly valve rubber seals are suitable for various pressure levels, such as low pressure, medium pressure, high pressure, ultra-high pressure, etc. In high-pressure and ultra-high-pressure environments, rubber seals can maintain good elasticity and sealing performance.

3. Medium: Rubber seals are suitable for a variety of media, such as gas, liquid, steam, corrosive media, etc. According to different materials and formulas, it can be used in various corrosive media environments.

4. Sealing performance: The seal has good sealing performance and can effectively prevent fluid leakage. In situations where strict sealing is required, such as chemical industry, petroleum, electric power and other fields, rubber seals are the ideal choice.

5. Wear resistance: Butterfly valve seals have good wear resistance and can maintain good appearance and performance during long-term use. In situations where long-term stable operation is required, such as chemical industry, petroleum and other fields, butterfly valve seals are a reliable choice.

Reviews

There are no reviews yet.