Description

What is the difference between EPDM and silicone rubber?

1. Processing aspect: Silicone rubber is better than EPDM;

2. In terms of temperature resistance: Silicone rubber has better temperature resistance, EPDM rubber has a temperature resistance of 150℃, and silicon rubber has a temperature resistance of 200℃;

3. Weather resistance: Ethylene-propylene rubber is better weather-resistant, and the rubber itself is environmentally friendly, but in a humid environment, ethylene-propylene rubber is less likely to breed bacteria;

4. Shrinkage ratio expansion ratio: now the shrinkage ratio of silicone rubber is higher than that of EPDM ;

5.The difference in combustion: when burning, silicone rubber will emit a bright fire, almost no smoke, no smell, and white residue after burning. EPDM, there is no such phenomenon;

6. In terms of tear and puncture resistance: EPDM is better;

7. Other aspects: Ethylene-propylene rubber has good ozone and high strength; high hardness and poor low temperature brittleness; silica gel has good elasticity and good low temperature performance; ordinary ozone, low strength!

If you need to customize your rubber parts, you could kindly offer the inormation as below, we could make the quotation based on that.

-

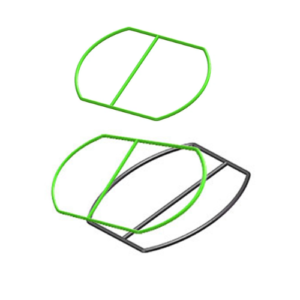

Material : EPDM

-

Color : Green

-

Hardness : SHA 60

-

Features: Anti Aging Outdoor.

Technical Parameter

| Properties | Unit | Data |

| Tensile Strength | Mpa | 10.5 |

| Elongation | % | 395 |

| Compression Set ( 150℃ x 22 h ) | % | 28 |

Reviews

There are no reviews yet.