Description

The role and classification of crane hydraulic valve seals

The main function of the crane hydraulic valve seal is to prevent the leakage of hydraulic oil between the inside and outside of the valve and ensure the normal operation of the hydraulic system. According to the different sealing parts, hydraulic valve seals can be divided into the following categories:

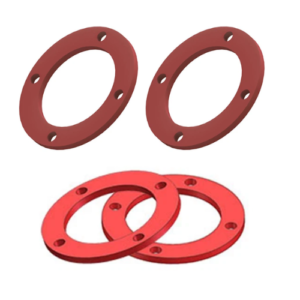

Static seals

It is used for sealing the immovable part of the valve, such as the seal between the valve body and the bonnet. This type of seal usually adopts the structural form of O-ring, flat gasket and so on.

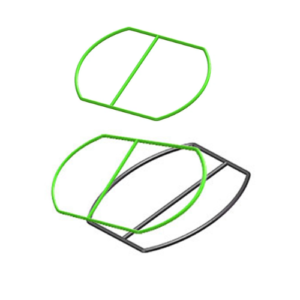

Dynamic seals

It is used for sealing the moving part of the valve, such as the seal between the spool and the seat. This type of seal usually adopts lip seal, V-shaped seal and other structural forms to adapt to the reciprocating movement of the valve core.

| Product name | Crane hydraulic valve seals |

| Product material | NBR, FKM, PU, etc |

| Hardness (Shore A) | 20 to 90 |

| Applicable temperature °C | -50 to 140 |

| Color | Black, orange, blue, yellow, green, custom |

| Size | Standard/ Custom |

| Advantage | Oil resistance, high temperature resistance, abrasion resistance |

| Application | Crane hydraulics |

| Certification | ISO: 9001, ISO: 14001, IATF: 16949 |

Material selection for crane hydraulic valve seals

The material selection of the hydraulic valve seal of the crane is directly related to its sealing performance and service life. When selecting a seal material, the following factors need to be considered:

Oil resistance

The seal material should have good oil resistance to prevent the erosion and swelling of the material by the oil.

High temperature resistance

During the working process of the crane, the hydraulic system may produce a higher temperature, so the seal material should have high heat resistance.

Abrasion resistance

The seals of the moving part of the valve will be subject to friction during the working process, so the material should have good wear resistance.

Elasticity and resilience

The seal material should have a certain elasticity and resilience to ensure that the seal can quickly return to its original state after being pressured and maintain a good sealing effect.

Common crane hydraulic valve seals materials include nitrile rubber (NBR), fluoroelastomer (FKM), polyurethane (PU), etc. These materials perform well in terms of oil resistance, high temperature resistance, wear resistance and elasticity, and can meet the requirements of crane hydraulic valve seals.

Reviews

There are no reviews yet.