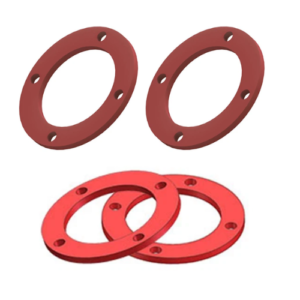

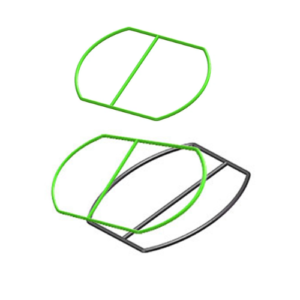

Description

Custom silicone gaskets are versatile sealing solutions tailored to meet specific application requirements. Made from high-quality silicone materials, these gaskets offer a range of benefits and applications across various industries. Here’s a detailed overview of their features and applications:

Features:

High Temperature Resistance: Silicone gaskets excel in high-temperature environments, withstanding temperatures ranging from -60°C to 230°C (-76°F to 446°F). This heat resistance ensures reliable sealing performance in extreme conditions.

Chemical Resistance: Silicone gaskets exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, solvents, and oils. This chemical resistance makes them suitable for use in diverse industrial applications.

Flexible and Elastic: Silicone gaskets possess inherent flexibility and elasticity, allowing them to conform to irregular surfaces and provide a tight seal. This flexibility ensures effective sealing even in dynamic or challenging sealing environments.

Weather Resistance: With outstanding weather resistance properties, silicone gaskets maintain their sealing integrity when exposed to UV radiation, ozone, moisture, and harsh weather conditions. They are ideal for outdoor applications exposed to environmental elements.

FDA Compliance: Certain grades of silicone gaskets comply with FDA (Food and Drug Administration) regulations, making them suitable for use in food processing, pharmaceutical, and medical applications where hygiene and safety are paramount.

Applications:

Automotive Industry: Silicone gaskets are used in automotive engines, transmissions, and exhaust systems due to their heat resistance and durability.

Electronics: These gaskets provide sealing and insulation in electronic enclosures, connectors, and components, protecting sensitive electronics from moisture, dust, and contaminants.

Industrial Machinery: Silicone gaskets are utilized in industrial machinery, pumps, valves, and seals to prevent leaks and ensure reliable operation in harsh industrial environments.

Food and Beverage: FDA-compliant silicone gaskets are employed in food processing equipment, beverage dispensers, and food storage containers, maintaining sanitary conditions and preventing contamination.

Medical Devices: Silicone gaskets are used in medical devices, diagnostic equipment, and laboratory instruments, providing sealing and cushioning properties in critical healthcare applications.

Aerospace and Aviation: Silicone gaskets are utilized in aircraft engines, fuel systems, and cabin interiors, meeting stringent performance requirements for aerospace applications.

Reviews

There are no reviews yet.