Description

Extruded rubber seals are versatile and essential components used in various industries for sealing applications. Here’s a detailed overview of these products:

Material Composition: These seals are typically made from high-quality rubber compounds such as EPDM (ethylene propylene diene monomer), silicone, neoprene, or natural rubber. The choice of material depends on the specific requirements of the application, including factors such as temperature resistance, chemical compatibility, and durability.

Manufacturing Process: Rubber seals are produced through an extrusion process, where rubber material is forced through a die of the desired cross-sectional shape. This process allows for the creation of seals with precise dimensions and consistent quality.

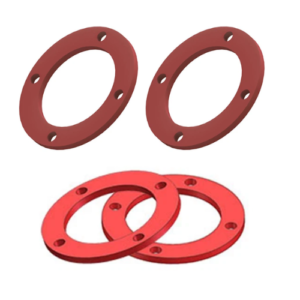

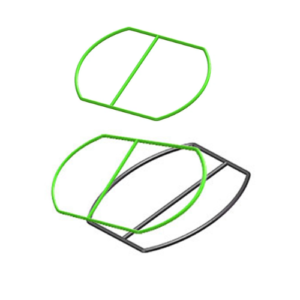

Types of Seals: Rubber seals come in various profiles and shapes, including O-rings, gaskets, tubing, channels, and profiles with specific geometries tailored to the sealing requirements of different applications.

Features and Properties:

Flexibility: Rubber seals are highly flexible, allowing them to conform to irregular surfaces and provide effective sealing.

Resistance to Environmental Factors: These seals offer excellent resistance to environmental factors such as temperature extremes, weathering, ozone, UV radiation, and chemical exposure.

Compression Set Resistance: They maintain their sealing properties even after prolonged compression, ensuring long-term performance.

Sealing Performance: Rubber seals provide reliable sealing against moisture, dust, air, and other contaminants, preventing leakage and ingress into sensitive components or enclosures.

Shock Absorption: Some rubber seals are designed to absorb shocks and vibrations, protecting equipment and machinery from damage.

Noise Reduction: Certain rubber seals also contribute to noise reduction by damping vibrations and sealing gaps that can transmit sound.

Customization: Manufacturers can customize rubber seals to meet specific application requirements, including size, shape, hardness, color, and material composition.

Applications: Rubber seals find widespread use across various industries, including automotive, aerospace, construction, electronics, HVAC (heating, ventilation, and air conditioning), marine, medical devices, and manufacturing. They are employed in sealing applications such as doors, windows, enclosures, gaskets, pipes, tubes, tanks, and machinery.

Reviews

There are no reviews yet.