Description

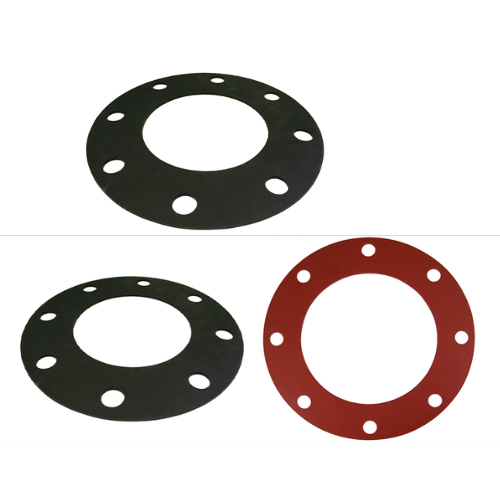

About Gate Valve Rubber Gasket

The function of the gate valve rubber gasket is to increase the contact area and reduce the contact pressure during the opening and closing process of the gate valve, thereby achieving sealing of the medium and preventing leakage of the medium. In addition, the gate valve rubber gasket also has excellent corrosion resistance and can resist the erosion of various chemical substances.

| Material | NR |

| Tensile strength | 17-25Mpa |

| Hardness | 40-90 Shore A |

| Density | 1.04-1.19g/cm³ |

| Temperature | -60~100℃ |

| Resilience | 50%-85% |

| Elastic modulus | 2~4Mpa |

| Elongation rate | 1000% |

Function

The gate valve is a mechanical device that cuts off or connects fluids, and the rubber gasket is one of the core components of the gate valve and shoulders the vital sealing task. When the gate valve is closed, the rubber gasket fills the gap between the valve seat and the gate plate, preventing fluid from passing through the valve. At the same time, rubber gaskets can also absorb vibrations caused by factors such as temperature changes, pressure fluctuations, and high-speed fluid impact, thereby protecting the valve from damage.

Structural Design

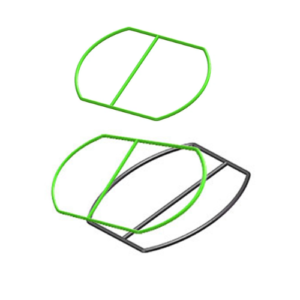

The structural design of the gate valve rubber gasket depends on its application scenario and functional requirements. Generally speaking, gate valve rubber gaskets are made of rubber materials and have elastic and sealing properties. Its structural design can include the following aspects:

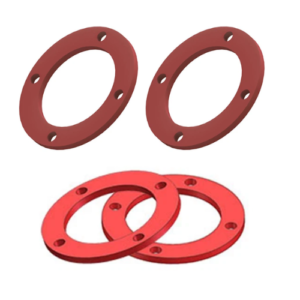

1. Shape design: Gate valve rubber gaskets are usually round or rectangular, and their diameter or width is designed according to actual needs.

2. Material selection: Choose appropriate rubber materials according to application scenarios and functional requirements, such as natural rubber, styrene-butadiene rubber, chloroprene rubber, etc.

3. Thickness design: The thickness of the gate valve gasket is designed according to actual needs, usually between 0.5-5mm.

4. Surface treatment: To improve the friction coefficient and anti-wear performance of the rubber gasket, surface treatment can be performed, such as sandblasting, bonding, etc.

5. Structural design: The structural design of the gate valve rubber gasket should consider its installation and use requirements, such as having good compressibility and resilience, being able to adapt to changes in temperature and pressure, etc.

Reviews

There are no reviews yet.