Description

| Carbon Steel: | Gasket | Stainless Steel: | Seal |

| Metal: | Seals Ring | Soft Iron: | Gasket |

High Light: Inconel 625 RX Ring Joint Gasket, HB160 RTJ ring gasket, Inconel 625 RTJ ring gasket

We Manufacture and supply high quality Ring joint Gaskets for high pressure and temperature service conditions. These gaskets are widely used in Refineries, Petrochemical Industries, Oil drilling well head equipments, Pressure Vessels, valves, Christmas Tree valves and Pipe lines. Ring joints Gasket are strictly manufactured as per API-6A and ASME B16.20 specification.

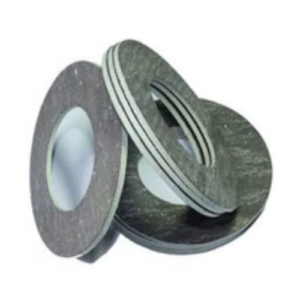

Type RX

–NB1 1/2″ to 24″ Class Rating 720 to 5000 ASME B16.20

–NB26″ to 36″ Class Rating 300 to 900 ASME B16.20 Series A

–NB1 1/2″ to 20″ Class Rating API 6A

RX Type Gasket

Style RX type RTJ gaskets are manufactured in accordance with both API 6A and ASME B16.20 to suit API 6B and ASME/ANSI B16.5 flanges.

Style RX is a pressure-energized adaptation of the standard Style R gasket. The RX is designed to fit the same groove design as a standard Style R, making the joints interchangeable. The modified design uses a pressure-energized effect that improves the efficiency of the seal as the internal pressure of the system increases.

| Common Materials | |||

| Material | HB Hardness | Temperature Limitations | Identification |

| Soft Iron | 90 | -60 to +400 °C | D |

| Low carbon steel | 120 | -40 to +500°C | S |

| 4%-6% Cr ½% Mo:F5 | 130 | -125 to +500°C | F5 |

| Stainless steel 304/304L | 160 | -250 to +650°C | S304 or 304L |

| Stainless steel 316/316L | 160 | -196 to +800°C | S316 or 316L |

| Stainless steel 321 | 160 | -250 to +870°C | S321 |

| Stainless steel 347 | 160 | -250 to +870°C | S347 |

| Stainless steel 410 | 170 | -20 to +500°C | S410 |

| Inconel 625 | – | 1000°C | 625 |

| Incoloy 825 | – | 1000°C | 825 |

| Hastelloy C-276 | – | 1000°C | C-276 |

| Duplex | – | 800°C | S31803 |

| Titanium | – | 540°C | TI |

Pressure: 2,000-5,000 PSI

| RING NO. | PRESSLURE ALASSES, API 6B | PITCH DLAMETER OF RING P |

OUTSIDE DLAMETER OF RING 0D |

WIDTH OF RING A |

HELCHT OF RING H |

WEIGHT Ibs. |

|||

| 720-960and 2000[Note(1)] |

2900[Note(1)] | 3000 | 5000 | ||||||

| Rx20 | 1 1/2 | – | 1 1/2 | 1 1/2 | 68.26 | 76.2 | 8.73 | 19.05 | 0.527 |

| Rx23 | 2 | – | – | – | 82.55 | 93.27 | 11.91 | 25.4 | 1.15 |

| Rx24 | – | – | 2 | 2 | 95.25 | 105.97 | 11.91 | 25.4 | 1.33 |

| Rx25 | – | – | – | 3 1/8 | 101.6 | 109.54 | 8.73 | 19.05 | 1.42 |

| Rx26 | 2 1/2 | – | – | – | 101.6 | 111.92 | 11.91 | 25.4 | 1.5 |

| Rx27 | – | – | 2 1/2 | 2 1/2 | 107.95 | 118.27 | 11.91 | 25.4 | 1.73 |

| Rx31 | 3 | – | 3 | – | 123.83 | 134.54 | 11.91 | 25.4 | 1.91 |

| Rx35 | – | – | – | 3 | 136.53 | 147.24 | 11.91 | 25.4 | 2.09 |

| Rx37 | 4 | – | 4 | – | 149.23 | 159.94 | 11.91 | 25.4 | 2.27 |

| Rx39 | – | – | – | 4 | 161.93 | 172.64 | 11.91 | 25.4 | 2.54 |

| Rx41 | 5 | – | 5 | – | 180.98 | 191.69 | 11.91 | 25.4 | 2.72 |

| Rx44 | – | – | – | 5 | 193.68 | 204.39 | 11.91 | 25.4 | 2.96 |

| Rx45 | 6 | – | 6 | – | 211.14 | 281.85 | 11.91 | 25.4 | 3.66 |

| Rx46 | – | – | – | 6 | 211.14 | 222.25 | 13.49 | 28.58 | 8.56 |

| Rx47 | – | – | – | 8(2) | 228.6 | 245.27 | 19.84 | 41.28 | 3.79 |

| Rx49 | 8 | – | 8 | – | 269.88 | 280.59 | 11.91 | 25.4 | 5.36 |

| Rx50 | – | – | – | 8 | 269.88 | 283.37 | 16.67 | 31.75 | 4.56 |

| Rx53 | 10 | – | 10 | – | 323.85 | 334.57 | 11.91 | 25.4 | 6.45 |

| Rx54 | – | – | – | 10 | 323.85 | 337.34 | 16.67 | 31.75 | 5.36 |

| Rx57 | 12 | – | 12 | – | 381 | 391.72 | 11.91 | 25.4 | 26.4 |

| Rx63 | – | – | – | 14 | 419.1 | 441.72 | 26.99 | 50.8 | 6.63 |

| Rx65 | 16 | – | – | – | 469.9 | 480.62 | 11.91 | 25.4 | 9.39 |

| Rx66 | – | – | 16 | – | 469.9 | 483.39 | 16.67 | 31.75 | 7.52 |

| Rx69 | 18 | – | – | – | 533.4 | 544.12 | 11.91 | 25.4 | 20.14 |

| Rx70 | – | – | 18 | – | 533.4 | 550.07 | 19.84 | 41.28 | 11.63 |

| Rx73 | 20 | – | – | – | 584.2 | 596.11 | 13.49 | 31.75 | 22.1 |

| Rx74 | – | – | 20 | – | 584.2 | 600.87 | 19.84 | 41.28 | 0.79 |

| Rx82 | – | 1 | – | – | 57.15 | 67.87 | 11.91 | 25.4 | 0.88 |

| Rx84 | – | 1 1/2 | – | – | 63.5 | 74.22 | 11.91 | 25.4 | 0.88 |

| Rx85 | – | 2 | – | – | 79.38 | 90.09 | 13.49 | 25.4 | 1.79 |

| Rx86 | – | 2 1/2 | – | – | 90.49 | 103.58 | 15.08 | 28.58 | 1.98 |

| Rx87 | – | 3 | – | – | 100.03 | 113.11 | 15.08 | 28.58 | 3.22 |

| Rx88 | – | 4 | – | – | 123.83 | 139.29 | 17.46 | 31.75 | 2.98 |

| Rx89 | – | 3 1/2 | – | – | 114.3 | 129.78 | 18.26 | 31.75 | 6.82 |

| Rx90 | – | 5 | – | – | 155.58 | 174.63 | 19.84 | 44.45 | 17.1 |

| Rx91 | – | 10 | – | – | 260.35 | 286.94 | 30.18 | 45.24 | 3.31 |

| Rx99 | 8(2) | – | 8(2) | – | 234.95 | 245.67 | 11.91 | 25.4 | – |

| Rx201 | – | – | – | 1 3/8 | 46.04 | 51.46 | 5.74 | 11.3 | – |

| Rx205 | – | – | – | 1 13/16 | 57.15 | 62.31 | 5.56 | 11.1 | – |

| Rx210 | – | – | – | 2 9/16 | 88.9 | 97.63 | 9.53 | 19.05 | – |

| RX215 | – | – | – | 4 1/16 | 130.18 | 140.89 | 11.91 | 25.4 | – |