Description

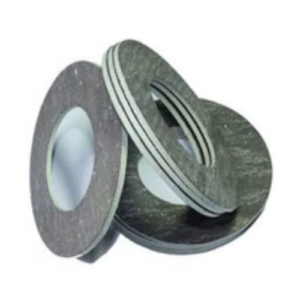

HEAT EXCHANGER GASKETS

Specially designed as Heat Exchanger Gaskets, metal jacket gaskets are commonly used in smooth flange applications. For heat exchangers, auto claves, columns, flue stacks, boilers, gas mains, valve caps, pumps, and similar services, they are ideal.

Camprofile gaskets used as Heat Exchanger Gaskets consist of a metal core with deep grooves with sealing materials on either side. Graphite, PTFE (Teflon), CAF or Metal (e.g. Aluminum or Silver) may be the sealing layers (depending on the service duty). Camprofiles can be used to provide an excellent seal without sealing layers, but there is a risk of damage to the surface of the flange.

The Very wide seating stress range (minimum to maximum stress) of the Camprofile gasket makes it

- Highly suitable for varying temperature and pressures.

- Less sensitive to assembly faults

- Suitable for light and heavily constructed flanges.

- Depending on layer material Camprofile gaskets are resistant to temperature upto 1000° C

- Resistant to media pressures upto 250 bar

- When assembled the layer thickness of the sealing material is extremely small (0.5mm) thus reducing leaks, reject rates and environment pollution.

- The gasket will not damage the flange surface and can be easily removed

- Camprofiles will not damage the flange faces even at extreme seating load.

- Excellent performance when subject to fluctuating temperature and pressures.

- Direct replacement for existing gaskets. No special flange finish is necessary

CLADDING METAL

Soft Iron, Low carbon steel, Monel Aluminium, Copper, Brass, Cupronickel 90%/10%, 70%/30%, Inconel 600,800 and different grades of Stainless Steel.

FILLER

Asbestos mill board, CAF, non-asbestos, PTFE, and Grafoil are common filler materials used. With many compartmental ribs, we have sufficient capacity to produce any shape and size for heat transfer equipment, coolers, condensers, joints, etc. Heat exchanger gaskets are more compressible than corrugated types of sole metal and provide better compensation for flange irregularities when sealing high pressures.