Description

| Carbon Steel: | Gasket | Stainless Steel: | Seal |

| Metal: | Seals Ring | Soft Iron: | Gasket |

| Temperature: | -200~800(℃) | Delivery: | In Stock |

| Standard: | Api 6a | Pressure: | High Pressure |

High Light: ASME B16.20 o ring gaskets, 347SS metal seal ring, ASME B16.20 metal seal ring

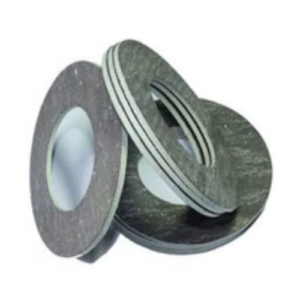

Bonnet Seal Ring Gasket Sizes

We currently offer bonnet gaskets for Type MS check valves in two sizes:

1-13/16” – 2-1/16” 5M-20M

3-1/16” – 4-1/16” 5M-20M

If you need help identifying the size needed, please contact us for personal assistance. We may also have compatible parts in stock that aren’t currently listed.

Competitive Pricing on Quality Bonnet Gaskets

API 6A Monogrammed MS Check Valves

Primary features:

1. Resistance to high temperature and pressure, suitable for high pressure flange

2. Excellent temperature resistance. Permanent temperature range -200℃to +550℃

3. Very high operating pressure limits (320 bar)

4. Good chemical resistance

5. High-grade, reinforced and blow out safe gasket as per UW (Healty and safety at Work Act), high operating safe

6. Very low leakage rate, meets TA-LUFT requirement

7. No ageing, no embitterment, even at high temperature

8. Asbestos-free, physiologically harmless, disposal with domestic waste

9. Good handling during transport, installation and removal. Mechanically stable, scratch-resistant

Thus Gasket supplies ring joint gaskets (RTJ Gasket) with the hardness numbers as follows:

| GASKET MATERIALS | BRINELL HARDNESS NUMBER (max) | ROCKWELL HARDNESS NUMBER (max) | IDENTIFICATION |

|---|---|---|---|

| Soft iron | 90 | 56 | D |

| Low carbon steel | 120 | 68 | S |

| 4-6% Chrome 1/2% molybdenum | 130 | 72 | F5 |

| 304 Stainless Steel | 160 | 83 | S304 |

| 316 Stainless Steel | 160 | 83 | S316 |

| 347 Stainless Steel | 160 | 83 | S347 |

| Material | Identification | Material No. | Hardness | Temperature (oC) | |

| Min | Max. | ||||

| Soft Iron | D | – | 90 | -40 | 500 |

| Low Carbon Steel | S | – | 120 | -40 | 500 |

| Stainless Steel 304 | 304SS | 1.4301 | 160 | -250 | 550 |

| Stainless Steel 304L | 304L SS | 1.4306 | 160 | -250 | 550 |

| Stainless Steel 316 | 316SS | 1.4401 | 160 | -100 | 550 |

| Stainless Steel 316L | 316L SS | 1.4404 | 160 | -100 | 550 |

| Stainless Steel 321 | 321SS | 1.4541 | 160 | -250 | 550 |

| Stainless Steel 347 | 347SS | 1.4450 | 160 | -250 | 500 |

| Stainless Steel 410 | 410SS | 1.4000 | 170 | -20 | 850 |

| Aluminum | Al | 3.0255 | 30 | -250 | 300 |

| Copper | Cu | 2.0090 | ca.80 | -250 | 400 |

| Brass | CuZn37 | 2.0321 | ca.60 | -100 | 350 |

| Nickel 200 | Ni200 | 2.4066 | 110 | -250 | 600 |

| Monel 400 | 400 | 2.4360 | 150 | -125 | 600 |

| Inconel 600 | 600 | 2.4816 | 150 | -100 | 950 |

| Hastelloy B2 | B2 | 2.4617 | 230 | -200 | 450 |

| Titanium | Ti | 3.7025 | ca.215 | -250 | 350 |

Marking and Identification (standard):

The outer surface of each Ring Type Joint should show the manufacturer’s name or a trademark, the gasket number like R67, RX37 or BX155, gasket’s material in abbreviation(check below our chart), as well as the standards like ASME B16.20, API 6A, API 17D, etc.

Materials

RTJ gaskets are available as standard in soft metal and in 304, 316 and stainless steels. Versions in other materials on request.

Standards and approvals

All RTJ gaskets are manufactured to API standards, guaranteeing consistent quality.

Recommended applications

Industries

- Oil & gas industry

- Petrochemical industry

- Flange connections

- Pipe connections

Functional description

Under axial compressive load, ring type joints plastically deform and flow into the irregularities of the flange groove. Since the contact area of the ring type joint is relatively small, a very high compressive load results between the sealing surface of the ring type joint and the flange groove. This surface pressure is further increased especially by the RX and BX RTJ variants. Both variants are able to seal extremely high internal pressures. RTJ gaskets are produced from metal, so they remain in their compressed form, even when the surface pressure is relaxed. The sealing function of the RTJ gasket is reinforced by the axial forces acting on the sealing surfaces