Description

| Carbon Steel: | Gasket | Stainless Steel: | Seal |

| Metal: | Seals Ring | Soft Iron: | Gasket |

High Light: Inconel 625 BX Ring Joint Gasket, 600LB RTJ gasket types, Inconel 625 RTJ gasket types

We can offer more than 30 kinds of materials, such as 321SS, 347SS, 316SS, 304SS, Inconel 625, Monel 400, INCOLY 825, Nickel 200, Duplex F44, soft iron, low carbon steel and so on. We have over 10 years experience in export business.

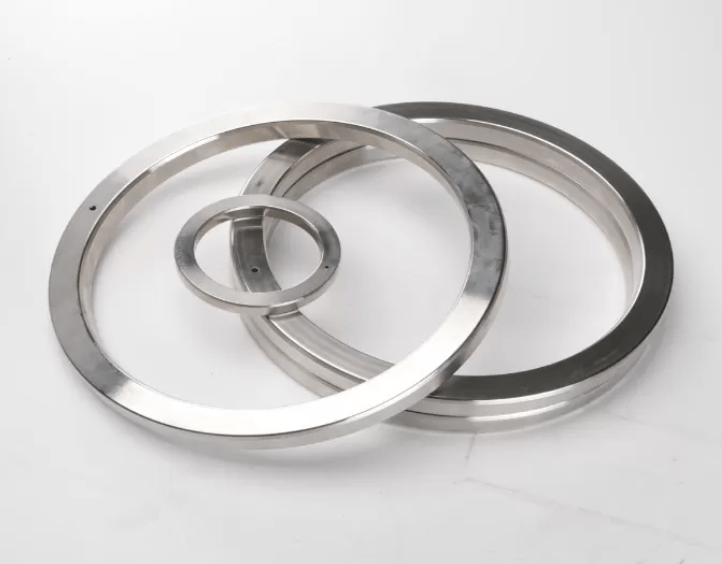

The BX type RTJ gaskets are manufactured in accordance with API 6A and are suitable for use in high pressure API 6BX flanges. The gaskets form a metal to metal seal on assembly and the efficiency improves as internal pressure increases. All BX sizes have a pressure relief hole to equalize pressure across sealing faces.

Type BX

–NB1 11/16″ to 21 1/4″ Class Rating 5000 to 20000 ASME B16.20

» BX Ring gasket Suitable for use on API 6BX Flanges up to Class 20000

» During installation the ring is compressed inwards to provide

additional sealing stress

» Pressure energised; as the internal pressure increases the

sealing force increases

» Type BX rings are supplied with pressure relief holes to avoid

compressing fluid beneath the gasket

» Can be drilled with additional hole to create a gasket suitable

for subsea installation Type “SBX”

As a result of metal to metal sealing media they are made to be free of indentations, tool marks etc and have a surface finish of maximum,

BX – 32 microinches Ra (0.8 micrometer Ra)

Type BX operates in 20,000 psi with non interchangeability. Type BX has a pressure passage hole for pressure equalization on each sealing face sides.

The hardness of the ring gasket should always be 30% lesser than the hardness of the flanges to prevent flange deformation

Dimensions and Tolerances for Ring Joint Gaskets and Grooves are covered in API 6A and ASME B16.20.

Ring type joint gaskets(RTJs) are designed for high pressure applications. They are available in a variety of forms to suit different flange formats . RTJs can be used for very high and/or fluctuating pressures (up to 1500 bar), depending on the profile selected. Material selection determines use for high temperatures (up to i000°C) and in aggressive media. To ensure proper sealing the surfaces of contact between the gaskets and flange have to be carefully processed. The small sealing area and high contact pressure results in excellent sealability.

| Common Materials | |||

| Material | HB Hardness | Temperature Limitations | Identification |

| Soft Iron | 90 | -60 to +400 °C | D |

| Low carbon steel | 120 | -40 to +500°C | S |

| 4%-6% Cr ½% Mo:F5 | 130 | -125 to +500°C | F5 |

| Stainless steel 304/304L | 160 | -250 to +650°C | S304 or 304L |

| Stainless steel 316/316L | 160 | -196 to +800°C | S316 or 316L |

| Stainless steel 321 | 160 | -250 to +870°C | S321 |

| Stainless steel 347 | 160 | -250 to +870°C | S347 |

| Stainless steel 410 | 170 | -20 to +500°C | S410 |

| Inconel 625 | – | 1000°C | 625 |

| Incoloy 825 | – | 1000°C | 825 |

| Hastelloy C-276 | – | 1000°C | C-276 |

| Duplex | – | 800°C | S31803 |

| Titanium | – | 540°C | TI |

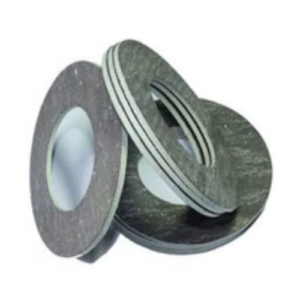

In order to reduce turbulent flow in adjoining flanges and prevent gasket/flange erosion Goodrich Gasket offers SPECIAL R, RX type joints with PTFE inserts. We also offers Nitrile Rubber coated ring joint gaskets (RTJ Gasket) used in pressure testing applications and as a protection for flange grooves and surfaces. Ring joint flanges with different ring groove diameters are sealed by Transition Ring joints, a different size and same PCD combination rings. Blind Ring joints, a standard ring joint with integral solid metallic centers blanks off flanges and pipe work. Flange Guards of closed cell neoprene foam readily compress under load protecting outside diameter of Ring joints in corrosive environments.

Designs are also available for Subsea applications.

| RING NO. | PRESSLURE ALASSES, API 6BX | OUTSIDE DIAMETER OF RING OD |

HELCHT OF RING H |

WIDTH OF RING A |

HOLE SIZE D |

GASKET | |||||

| 2000 | 3000 | 5000 | 10000 | 15000 | 20000 | ||||||

| Bx150 | – | – | – | 1 11/16 | 1 11/16 | – | 72.19 | 9.3 | 9.3 | 1.59 | 0.295 |

| Bx151 | – | – | – | 1 13/16 | 1 13/16 | 1 13/16 | 76.4 | 9.63 | 9.63 | 1.59 | 0.337 |

| Bx152 | – | – | – | 2 1/16 | 2 1/16 | 2 1/16 | 84.68 | 10.24 | 10.24 | 1.59 | 0.425 |

| Bx153 | – | – | – | 2 9/16 | 2 9/16 | 2 9/16 | 100.94 | 11.38 | 11.38 | 1.59 | 0.632 |

| Bx154 | – | – | – | 3 1/16 | 3 1/16 | 3 1/16 | 116.84 | 12.4 | 12.4 | 1.59* | 0.875 |

| Bx155 | – | – | – | 4 1/16 | 4 1/16 | 4 1/16 | 147.96 | 14.22 | 14.22 | 1.59 | 1.22 |

| Bx156 | – | – | – | 7 1/16 | 7 1/16 | 7 1/16 | 237.92 | 18.62 | 18.62 | 3.18 | 4.14 |

| Bx157 | – | – | – | 9 | 9 | 9 | 294.46 | 20.98 | 20.98 | 3.18 | 6.55 |

| Bx158 | – | – | – | 11 | 11 | 11 | 352.04 | 23.14 | 23.14 | 3.18 | 9.6 |

| Bx159 | – | – | – | 13 5/8 | 13 5/8 | 13 5/8 | 426.72 | 25.7 | 25.7 | 3.18 | 14.41 |

| Bx160 | – | – | 13 5/8 | – | – | – | 402.59 | 23.83 | 13.74 | 3.18 | 6.75 |

| Bx161 | – | – | 16 3/4 | – | – | – | 491.41 | 28.07 | 16.21 | 3.18 | – |

| Bx162 | – | – | 16 3/4 | 16 3/4 | 16 3/4 | – | 475.49 | 14.22 | 14.22 | 1.59 | – |

| Bx163 | – | – | 18 3/4 | – | – | – | 556.16 | 30.1 | 17.37 | 3.18 | – |

| Bx164 | – | – | – | 18 3/4 | 18 3/4 | – | 570.56 | 30.1 | 24.59 | 3.18 | – |

| Bx165 | – | – | 21 1/4 | – | – | – | 624.71 | 32.03 | 18.49 | 3.18 | – |

| Bx166 | – | – | – | 21 1/4 | – | – | 640.03 | 32.03 | 26.14 | 3.18 | – |

| Bx167 | 26 3/4 | – | – | – | – | – | 759.36 | 35.87 | 13.11 | 1.59 | – |

| Bx168 | – | 26 3/4 | – | – | – | – | 765.25 | 35.87 | 16.05 | 1.59 | – |

| Bx169 | – | – | – | 5 1/8 | – | – | 173.51 | 15.85 | 12.93 | 1.59 | – |

| Bx170 | – | – | – | 6 5/8 | 6 5/8 | – | 218.03 | 14.22 | 14.22 | 1.59 | – |

| Bx171 | – | – | – | 8 9/16 | 8 9/16 | – | 267.44 | 14.22 | 14.22 | 1.59 | – |

| Bx172 | – | – | – | 11 5/32 | 11 5/32 | – | 333.07 | 14.22 | 14.22 | 1.59 | – |

| BX303 | 30 | 30 | – | – | – | – | 852.75 | 37.95 | 16.97 | 1.59 | – |