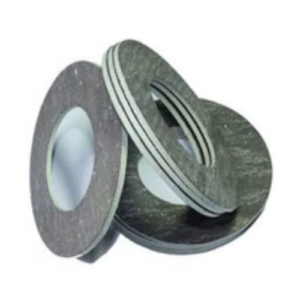

Description

| Stainless Steel: | Seals Ring | Api: | Gasket |

| Wellhead: | Ring Joint Gasket | Carbon Stell: | Gasket |

Standard: API 6A,ASME/ANSI B16.5,BS1560

High Light: API 6A Soft Iron Ring Joint Gasket, K42544 ring joint gasket, API 6A flat ring gasket

SEALS RING GASKET high pressure and high-temperature according to API 6a asme16.20

We provides superior products and best service to the customers by bringing in advanced CNC machines, sawing machines, spectrograph, desktop hardness, laser marking machine, coating thickness gauge and other equipments.

| MAXIMUM HARDNESS | ||||

| MATERIAL | UNS NUMBER | BRINELL | ROCKWELL B† | IDENTIFICATION |

| Soft Iron | 90 | 56 | D | |

| Low Carbon Steel | 120 | 68 | S | |

| 4–6% Chrome 1/2% Moly | K42544 | 130 | 72 | F5 |

| Type 304 Stainless Steel | S30400 | 160 | 83 | S304 |

| Type 316 Stainless Steel | S31600 | 160 | 83 | S316 |

| Type 347 Stainless Steel | S34700 | 160 | 83 | S347 |

| Type 410 Stainless Steel | S41000 | 170 | 86 | S410 |

| Titanium Grade 2 | R50400 | |||

| Alloy 600 | N06600 | 200 | ||

| Alloy 625 | N06625 | 200 | ||

| Alloy 800 | N08800 | 200 | ||

| Alloy 825 | N08825 | 160 | ||

| Hastelloy | N10001 | 200 | ||

| Alloy C276 | N10276 | 200 | ||

| SMO 254 | S32154 | 180 | ||

| Zeron 100 | 200 | |||

| Super Duplex | S31803 | |||

we supplies ring joint gaskets (RTJ Gasket) with the hardness numbers as follows:

| Common Materials | |||

| Material | HB Hardness | Temperature Limitations | Identification |

| Soft Iron | 90 | -60 to +400 °C | D |

| Low carbon steel | 120 | -40 to +500°C | S |

| 4%-6% Cr ½% Mo:F5 | 130 | -125 to +500°C | F5 |

| Stainless steel 304/304L | 160 | -250 to +650°C | S304 or 304L |

| Stainless steel 316/316L | 160 | -196 to +800°C | S316 or 316L |

| Stainless steel 321 | 160 | -250 to +870°C | S321 |

| Stainless steel 347 | 160 | -250 to +870°C | S347 |

| Stainless steel 410 | 170 | -20 to +500°C | S410 |

| Inconel 625 | – | 1000°C | 625 |

| Incoloy 825 | – | 1000°C | 825 |

| Hastelloy C-276 | – | 1000°C | C-276 |

| Duplex | – | 800°C | S31803 |

| Titanium | – | 540°C | TI |

Ring Type Joints are a kind of forged ring which will be installed into the machined groove of an RTJ flange. After tightening the bolts, the ring joints will be compressed between the flanges into the grooves, and the rings will give an efficient sealing function after deforming. In this way, the metals material for the API ring gaskets is typically chosen to be softer than the flange material in order to prevent any damages to the flanges.

Ring joint gaskets are widely used in refinery, petrochemical and oil field drilling industries. and the rings are generally used for high pressure and high-temperature applications.

‘R’ series Ring Type Joints can contain pressure up to 10,000 PSI.

Programming interface ring Joint gaskets come in two fundamental sorts, an oval cross segment and an octagonal cross segment. These essential shapes are utilized in pressures up to 10,000 Rubber Seals and Gasket. The measurements are institutionalized and require uniquely notched spines. The octagonal cross segment has a higher fixing proficiency than the oval and would be the favored gasket. Be that as it may, just the oval cross segment can be utilized in the old sort round base notch. The more up to date level base furrow configuration will acknowledge either the oval or the octagonal cross segment. The fixing surfaces on the ring joint sections must be easily completed to 63 smaller scale inches and to be liberated from shocking edges, apparatus or babble marks. They seal by an underlying line contact or an edging activity as the compressive powers are applied.