Description

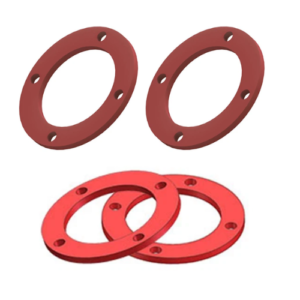

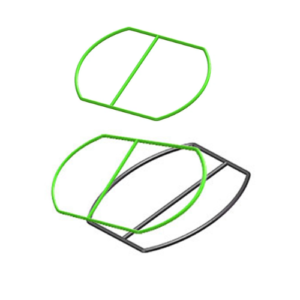

High pressure washer rubber seals

In pressure washers, the following accessories may use rubber seals

- High-pressure nozzle and nozzle: The high-pressure nozzle and nozzle are key components in the high-pressure cleaning machine, used to generate high-pressure water flow. They usually use rubber seals with the nozzle head to ensure good sealing at the connection between the nozzle and the nozzle head and prevent water leakage.

- Pump body seal: The water pump in a pressure washer usually includes a pump body, which contains the working parts of the pump. Pump bodies often require rubber seals to ensure proper pump operation and prevent leaks.

- High-pressure hose connection: Pressure washers use high-pressure hoses to deliver water flow. Hose connections, such as quick connectors, swivel joints, etc., usually require rubber seals to ensure the sealing of the connection to prevent water leakage.

- Control valve seal: The control valve in the high-pressure cleaner is used to control the switching and regulation of the water flow. These valves often require rubber seals to ensure the seal of the valve to prevent pressure leakage or uncontrolled flow of water.

- Pump Piston Seal: Some pressure washers use a plunger or piston pump to create a high-pressure flow of water. These pumps typically include a piston or plunger and require a rubber seal to ensure a tight seal between the piston or plunger and the pump body to prevent leakage.

| use | additive | ||

| Exterior | White | ||

| Physical properties | Rating | unit system | Test Methods |

| Specific surface area | 3 | m²/g | internal method |

| Particle size – (D50) | 20 | μm | internal method |

| Bulk density | 400 | g/l | ASTM D4895 |

| Additional information | |||

| Temperature range | Between -185°C and +250°C (intermittent/compound-specific between -200°C and +260°C) Melting point at approximately +327°C |

||

| Standard refers range | British Imperial (BS1806) and Metric (BS4518).

European Metric (ISO 3601), including German (DIN 3771), Swedish (SMS 1586/1588) and French (NFT 47 501). American (SAE, AMS, AS568) and Japanese Metric (JISB 2401). |

||

Reviews

There are no reviews yet.