Description

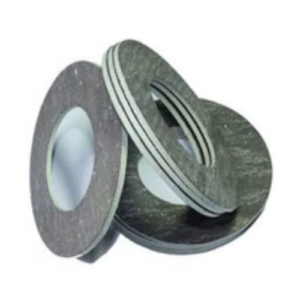

Subsea: Gasket

Stainless Steel: SEAL RING

Metal: GASKET

High Light: SBX 152 o ring gaskets, heatproof SBX Ring Gasket, SBX 152 metal seal ring

| Ring number | Nominal size | Outside diameter of ring OD |

Height of ring H |

Width of ring A |

Diameter of flat ODT |

Width of flat Typ. C |

Hole size D |

Corner Radius Typ. R |

|

| SBX 151 | 1-13/16 | 3.008 | 0.379 | 0.379 | 2.954 | 0.325 | 0.06 | 0.06 | |

| SBX 152 | 2-1/16 | 3.334 | 0.403 | 0.403 | 3.277 | 0.346 | 0.06 | 0.06 | |

| SBX 153 | 2-9/16 | 3.974 | 0.448 | 0.448 | 3.91 | 0.385 | 0.06 | 0.06 | |

| SBX 154 | 3-1/16 | 4.6 | 0.488 | 0.488 | 4.531 | 0.419 | 0.06 | 0.06 | |

| SBX 155 | 4-1/16 | 5.825 | 0.56 | 0.56 | 5.746 | 0.481 | 0.06 | 0.06 | |

| SBX 156 | 71/16 | 9.367 | 0.733 | 0.733 | 9.263 | 0.629 | 0.12 | 0.12 | |

| SBX 157 | 9 | 11.593 | 0.826 | 0.826 | 11.476 | 0.709 | 0.12 | 0.12 | |

| SBX 158 | 11 | 13.86 | 0.911 | 0.911 | 13.731 | 0.782 | 0.12 | 0.12 | |

| SBX 159 | 13-5/8 | 16.8 | 1.012 | 1.012 | 16.657 | 0.869 | 0.12 | 0.12 | |

| SBX 160 | 13-5/8 | 15.85 | 0.938 | 0.541 | 15.717 | 0.408 | 0.12 | 0.12 | |

| SBX 161 | 16-3/4 | 19.347 | 1.105 | 0.638 | 19.191 | 0.482 | 0.12 | 0.12 | |

| SBX 162 | 16-3/4 | 18.72 | 0.56 | 0.56 | 18.641 | 0.481 | 0.06 | 0.06 | |

| SBX 163 | 18-3/4 | 21.896 | 1.185 | 0.684 | 21.728 | 0.516 | 0.12 | 0.12 | |

| SBX 164 | 18-3/4 | 22.463 | 1.185 | 0.968 | 22.295 | 0.8 | 0.12 | 0.12 | |

| SBX 165 | 21-1/4 | 24.595 | 1.261 | 0.728 | 24.417 | 0.55 | 0.12 | 0.12 | |

| SBX 166 | 21-1/4 | 25.198 | 1.261 | 1.029 | 25.02 | 0.851 | 0.12 | 0.12 | |

| SBX 169 | 5-1/8 | 6.831 | 0.624 | 0.509 | 6.743 | 0.421 | 0.06 | 0.06 |

product description

The SBX series is an underwater cushion ring standardized by American Petroleum. BX and SBX will be installed to suitable flanges. S as the first letter means that the gasket has cross holes. When formulated underwater, an initial pressure-free metal-to-metal contact between the gasket and the flange groove is allowed.

Manufacturers, rental tool companies, and operators indicated that the pressure control equipment is unlikely to fail during service by conducting a hydrostatic pressure test before transporting the equipment to the site. Few equipment that meets industrial requirements fails catastrophically. Normally, due to accidental tightening of bolts, connection leakage occurs and the connecting bolts need to be tightened again. In order to prevent leakage, re-tightening requires more torque than the connection required for the first attempt to not leak. Interestingly, in order to further tighten the previously leaked connection, the phenomenon of the underwater connection development is accurately replicated. The leak connection allows the test liquid (usually water) to enter the ring groove behind the backing ring. Further try to tighten the connection surface of the water incompressibility problem. Testing with SBX gaskets will eliminate this re-tightening problem, but the high cost of these gaskets is inhibiting.

Performance characteristics:

1. Comply with the use of API17D subsea wellhead and Christmas tree equipment.

2. SBX type backing ring solves the problems encountered when connecting 6BX and/or 17D ring joint flanges underwater.

3. The SBX gasket ring has a drain hole inside, which is connected to the balance hole to ensure that any liquid remaining behind the gasket on either side will flow to the inner hole of the component when connected together. This allows the connection to be closed as designed, and the backing ring is molded to form a permanent seal.

4. The distorted metal-to-metal gasket should no longer be used.

Material selection:

Soft iron, low carbon steel, ss410, ss304, ss316, ss347, F5, F11, copper, aluminum, 600 Inconel, 625 Inconel, 800 Inconel, 825 Inconel, 400 Monel copper-nickel alloy , Titanium alloy, 200 nickel alloy, 276 nickel molybdenum alloy, 702 zirconium alloy