Description

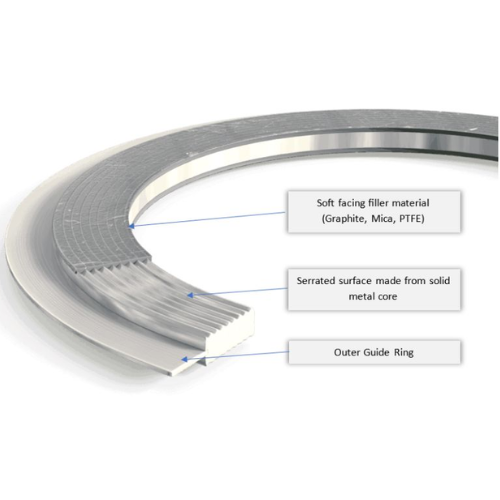

Basic Type Kammprofile Gasket

- JR Kammprofile Gasket with integral Outer Ring

- SJ Kammprofile Gasket with Loose Outer Ring

- Temperature:~650℃

- Pressure:6.4~25.0MPa

- Gasket Factor:m-4.25

- Gasket Seating:y=70MPa

Application:

Kammprofile gasket is the preferred gasket when improved performance at low seating stresses is required. It features excellent anti-blow-out properties linked with the reliably of a solid metal-to-metal seal combined with a soft sealing face to provide a tighter joint. It is particularly suitable for applications where high temperature, pressures and fluctuating conditions are encountered. Non-metal cover layers ensure that flanges are not damaged, even at extreme loads. This gasket is an ideal replacement for problem applications associated with metal jacketed gaskets, for heat exchangers, vessels and reactors and various flange connections.

| Metal Materials | Germany Standard | HB | Temperature (℃) | Density g/cm3 |

|---|---|---|---|---|

| Carbon Steel | 1.1003/1.0038 | 90~120 | -60~500 | 7.85 |

| SS304/SS304L | 1.4301/1.4306 | 130~180 | -250~550 | 7.9 |

| SS316/SS316L | 1.4401/1.4404 | 130~180 | -250~550 | 7.9 |

| Copper | 2.0090 | 50~80 | -250~400 | 8.9 |

| Aluminum | 3.0255 | 20~30 | -250~300 | 2.73 |

【Kammprofile Gasket】Nonmetal MaterialsThe other materials can be available as the requirement of the buyer. Flexible Graphite, ExpandedPTFE and etc.