Description

Features of Modified PTFE Gasket Materials

- Excellent chemical resistance

- Improved performance over conventional PTFE

- Resistance to cold flow / creep

- Temperature stable from -268°C to +260°C

- Suitable for high temperature – pressure applications

- Improved seal & excellent bolt torque retention

- Outstanding dimensional stability under thermal stress

- Reduced product loss and emissions

- Approved for pharmaceutical and food processing use

- TUV certified in accordance with TA-Luft requirements

- Resistance to wear and abrasion

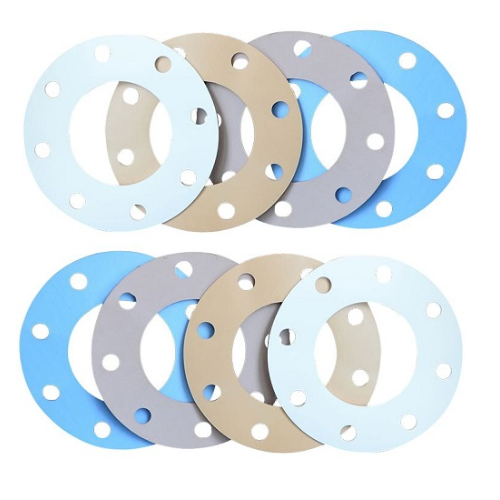

- Supplied as precision cut gaskets to any shape & size and quantity or in sheet form to max size 1500mm x 1500mm

- Available in a range of 5 thicknesses 0.8mm/1.0mm/1.6mm/2.0mm and 3.2mm

| Color | Tawny | Blue | Off-white | Black |

|---|---|---|---|---|

| Composition | PTFE with silica | PTFE with glass microspheres | PTFE with barium sulfate | PTFE with graphite |

| TemperatureMinimumCont. max. | -268 oC+260 oC | -268 oC+260 oC | -268 oC+260 oC | -268 oC+260 oC |

| Pressure bar | 75 | 55 | 55 | 75 |

| Sealability cm3/s (GB/T9129-2003) | < 1 x 10-3 | < 1 x 10-3 | < 1 x 10-3 | < 1 x 10-3 |

| Creep Relaxation % ASTM F38 | 20 | 35 | 18 | 35 |

| Compressibility Range % ASTM F36-99 | 10~15 | 25~40 | 5~12 | 7~19 |

| Recovery % ASTM F36-99 | > 21 | >25 | >35 | >35 |

| Tensile Strength N/mm2 ASTMF 152-95 | 13 | 12 | 11 | 11 |

| Flammability | Will not support flame | |||

| Bacterial Growth | Will not support |

Reviews

There are no reviews yet.