Description

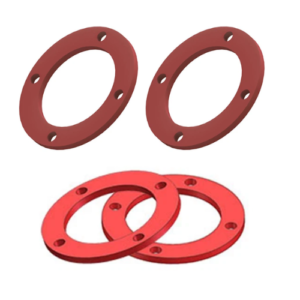

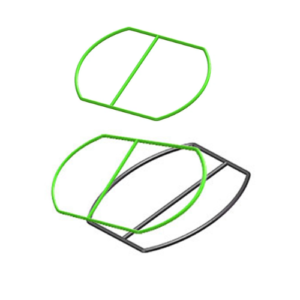

Moulded Rubber Products are precision-manufactured items produced through the rubber molding process. These products, tailored to specific applications and customer requirements, exhibit exceptional wear resistance, corrosion resistance, and high-temperature durability. Employing high-quality rubber materials like nitrile rubber, acrylic rubber, silicone, etc., they find widespread use in automotive, electronics, industrial machinery, and aerospace sectors. Common applications include shock absorbers, seals, and sound insulation components.

Key Features:

Material Characteristics:the Rubber Products typically utilize high-grade rubber materials, ensuring excellent wear, corrosion, and high-temperature resistance.

Applications: Widely employed in automotive, electronics, industrial machinery, and aerospace industries for diverse applications like shock absorption, sealing, and sound dampening.

Custom Design: These products can be customized to meet specific client requirements, allowing for adjustments in shape, size, hardness, and other parameters.

Manufacturing Process: Advanced rubber molding processes, encompassing rubber compounding, extrusion or compression, and vulcanization, ensure consistent quality and precision.

Performance Advantages: the Rubber Products offer superior mechanical properties, including elasticity, flexibility, and tensile strength. They also provide effective waterproofing, dust resistance, and sound insulation capabilities, enhancing equipment performance and longevity.

Reviews

There are no reviews yet.