Description

| Carbon Steel: | Gasket | Stainless Steel: | Seal |

|---|---|---|---|

| Metal: | Seals Ring | Manufacturer: | Factory |

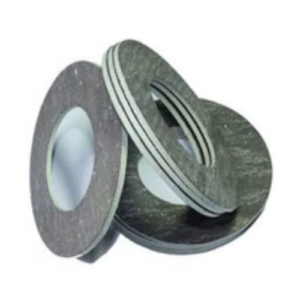

The working of ring joint gaskets (RTJ Gasket) can be explained by the axial compressive load causing them to deform and flow to irregularities in the flange grooves that it seals. As load bearing area of ring joint gaskets (RTJ Gasket) are small high surface stresses are produced between the sealing face and the groove, making it poor in recovery characteristics and unfit for reuse.

We manufacture from R 11 through R 105 to suit the following flange specifications:

The Octagonal cross section Ring Joint is the development oval cross section and offers a better sealing performance. Only oval cross section gaskets can be used when the flange grooves are with the round bottom. Both Octagonal and oval cross sectioned gaskets can be used when the grooves of the flange are having a flat bottom.

Surface finish of the Style R Ring Type Joint sealing faces (radiused ends of an Oval and the 23° angled faces of an Octagonal shape) shall not be greater than 1.6 μm Ra /63 μin RMS. Flexitallic Style R Ring Type Joints can bemanufactured in accordance with all relevant standardsto suit the following flange designations:

API 6A

ASME16.20

R Oval & Octagonal gasket ring Can be used for ASME B16.5 flange class 150 to 2500 and

API 6B to Class 5000

»Soft iron and carbon steel gaskets are zinc plated to prevent

corrosion

» All rings are marked with the ring number, material and the

date of manufacture and API designation

| Common Materials | |||

| Material | Brinell Hardness | Temperature Limitations | Identification |

| Soft Iron | 90 | -60 to +400 °C | D |

| Low carbon steel | 120 | -40 to +500°C | S |

| 4%-6% Cr ½% Mo:F5 | 130 | -125 to +500°C | F5 |

| Stainless steel 304/304L | 160 | -250 to +650°C | S304 or 304L |

| Stainless steel 316/316L | 160 | -196 to +800°C | S316 or 316L |

| Stainless steel 321 | 160 | -250 to +870°C | S321 |

| Stainless steel 347 | 160 | -250 to +870°C | S347 |

| Stainless steel 410 | 170 | -20 to +500°C | S410 |

| Inconel 625 | – | 1000°C | 625 |

| Incoloy 825 | – | 1000°C | 825 |

| Hastelloy C-276 | – | 1000°C | C-276 |

| Duplex | – | 800°C | S31803 |

| Titanium | – | 540°C | TI |

| GASKET MATERIALS | BRINELL HARDNESS NUMBER (max) | ROCKWELL HARDNESS NUMBER (max) | IDENTIFICATION |

|---|---|---|---|

| Soft iron | 90 | 56 | D |

| Low carbon steel | 120 | 68 | S |

| 4-6% Chrome 1/2% molybdenum | 130 | 72 | F5 |

| 304 Stainless Steel | 160 | 83 | S304 |

| 316 Stainless Steel | 160 | 83 | S316 |

| 347 Stainless Steel | 160 | 83 | S347 |