Description

Importance of Sewage treatment valve seals

Sewage treatment systems usually involve a variety of complex processes, including pre-treatment, biological treatment, and deep treatment. Valve seals play a pivotal role in these processes. Their main function is to ensure that when the valve is closed, it can effectively prevent the leakage of sewage, to ensure that the system is airtight and safe. At the same time, valve seals need to be corrosion and wear-resistant to cope with the complex chemical environments and mechanical movements found in wastewater treatment systems.

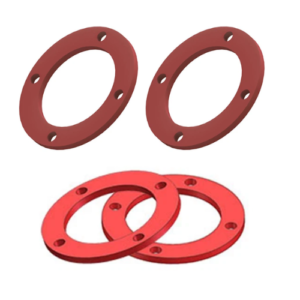

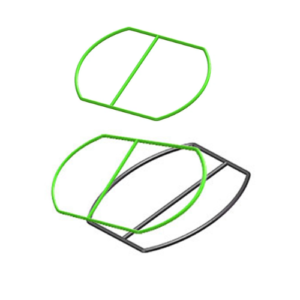

| Product name | Sewage treatment valve seals |

| Product material | Silicon carbide, alumina, cemented carbide, PTFE, etc |

| Hardness (Shore A) | 20 to 90 |

| Applicable temperature °C | -50 to 140 |

| Color | Black, orange, blue, yellow, green, custom |

| Size | Standard/ Custom |

| Advantage | Hydraulic cylinders, hydraulic pipelines, hydraulic valves |

| Application | Sewage treatment valve |

| Certification | ISO: 9001, ISO: 14001, IATF: 16949 |

Technical details of Sewage treatment valve seals

Sealing principle

The sealing principle of valve seals mainly depends on the contact pressure between the sealing surfaces and the characteristics of the sealing material. When the valve is closed, a certain contact pressure will be formed between the sealing surfaces, through the elastic deformation and compression of the sealing material to achieve the sealing effect. At the same time, the sealing material also needs to have excellent corrosion resistance and abrasion resistance, to ensure that in the long-term use of the process can maintain good sealing performance.

Material selection

The material selection of Sewage treatment valve seals is crucial. Common materials include silicon carbide, aluminum oxide, cemented carbide, PTFE and so on. These materials have good corrosion and wear resistance and can be used for a long time in the complex environment of the sewage treatment system. Among them, silicon carbide and alumina are excellent high-temperature structural ceramic materials, suitable for high-temperature and high-pressure wastewater treatment environments; cemented carbide has high bending resistance and thermal stability, suitable for occasions subjected to large mechanical stress; PTFE has stable chemical properties and high-temperature stability, suitable for chemically corrosive wastewater treatment environments.

Structural design

The structural design of the valve seal is also an important factor affecting its performance. Common valve seal structure includes packing seal, elastic seal and metal seal. Packing seal through the filling of flexible packing material to achieve sealing, suitable for low-pressure and low-speed occasions; elastic sealing is the use of elastic material elastic deformation to achieve sealing, suitable for medium-pressure and medium-speed occasions; metal seals through the metal surface of the pressure and deformation to achieve sealing, suitable for high-pressure and high-speed occasions. In the sewage treatment system, it is necessary to choose the appropriate seal structure according to the specific process requirements and working environment.

Reviews

There are no reviews yet.