Description

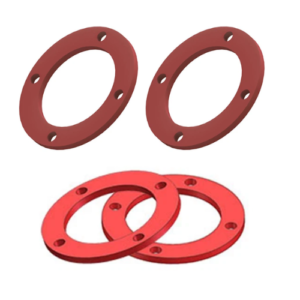

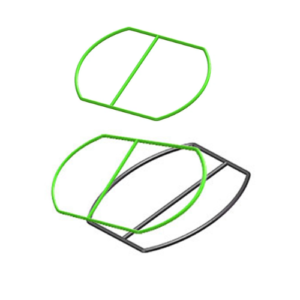

Product: Silicone Rubber Button Pads

Color: customer request

Material: Silicone

Types: single-point silicone buttons, remote control silicone buttons, conductive silicone buttons, mobile phone silicone buttons, light touch silicone buttons, light-transmitting silicone buttons, keyboard buttons, cipher buttons, car buttons, membrane buttons, laser engraving buttons, reset buttons, Home button, pc button, learning machine button, pos machine button, cipher button, digital product button, p+r button, SMD silicone button, etc.!

Application: electronic calculators, remote controls, telephones, wireless telephones, electronic toys, computer keyboards, learning machine keys, cipher keys, digital product keys;

Silicone Rubber Button Pads have excellent heat resistance, cold resistance, environmental resistance, electrical insulation, fatigue resistance and other characteristics.

Scope of application

Silicone Rubber Button Pads are often used in electronic calculators, remote controls, telephones, wireless telephones, electronic toys, computer keyboards, learning machine keys, cipher keys, digital product keys;

Considerations

Silicone Rubber Button Pads production needs to consider the diameter, length, width and height of the silicone product, button travel distance, pressing force requirements, product hardness, color, conductivity requirements, etc.;

Production process

Silicone Rubber Button Pads is a silicone rubber product produced by high temperature vulcanized rubber as the main raw material through the molding process of vulcanization. A finished silicone keyboard needs to go through the following processes:

1. Raw material preparation (also known as rubber mixing, material preparation, etc.): Including mixing of raw rubber, color matching, weight calculation of raw materials, etc.

2. Vulcanization molding (also known as hydraulic molding): High-pressure vulcanization equipment is used to undergo high-temperature vulcanization to make the silicone raw material into a solid state.

3. Phifeng (also known as processing, deburring, etc.): The silicone products that come out of the mold will be accompanied by some useless burrs and holes, which need to be removed; in the industry, this process is done by hand, and some factories are also useful The punch is complete.

4. Silk screen printing: This process is only used on some silicone keyboards with patterns on the surface, such as English letters and Arabic numerals on the silicone keyboard. In order to make it easy for users to operate the keys, it is often necessary to silk screen the corresponding characters of the mobile phone keyboard in the corresponding position.

5. Surface treatment: Surface treatment includes dust removal with air gun;

6. Fuel injection: Silicone keyboard is easy to absorb dust in the air under normal conditions, and has a certain viscosity. Spray a thin layer of feel oil on the surface of the silicone keyboard to prevent dust and ensure the feel.

7. Others: Other processes include some additional functions given by the merchants to the silicone keyboard, such as dispensing glue, laser engraving, P+R synthesis, optimizing packaging, and assembling with other materials and components.

Reviews

There are no reviews yet.