Description

Spiral Wound Gasket is widely used for sealing flange joints, manhole and handhole covers, tube covers, boilers, heat exchangers, pressure vessels, pumps, compressors and valves, in industries such as petrochemical, pharmaceutical, shipbuilding, and food processing, in power industries and nuclear power stations. They are ideal for steam, oil, liquids, gases, acids, alkalines, various organic mediums and solvents. It can be manufactured with any material as per customers requirement in accordance with the standard ASME, DIN, BS, API or to customer??s specification.

Spiral wound gaskets are produced in several style and combination of materials to fit the most stringent application. Spiral wound gaskets are usually of circular shape, however we can produce them in other shapes such as: oval, rectangular, with round corners, etc. Our standard production program comprises a range of spiral wound gaskets with inner diameters of 10mm to 3000mm and non-standard dimensions and shapes, and larger diameters are available on request.

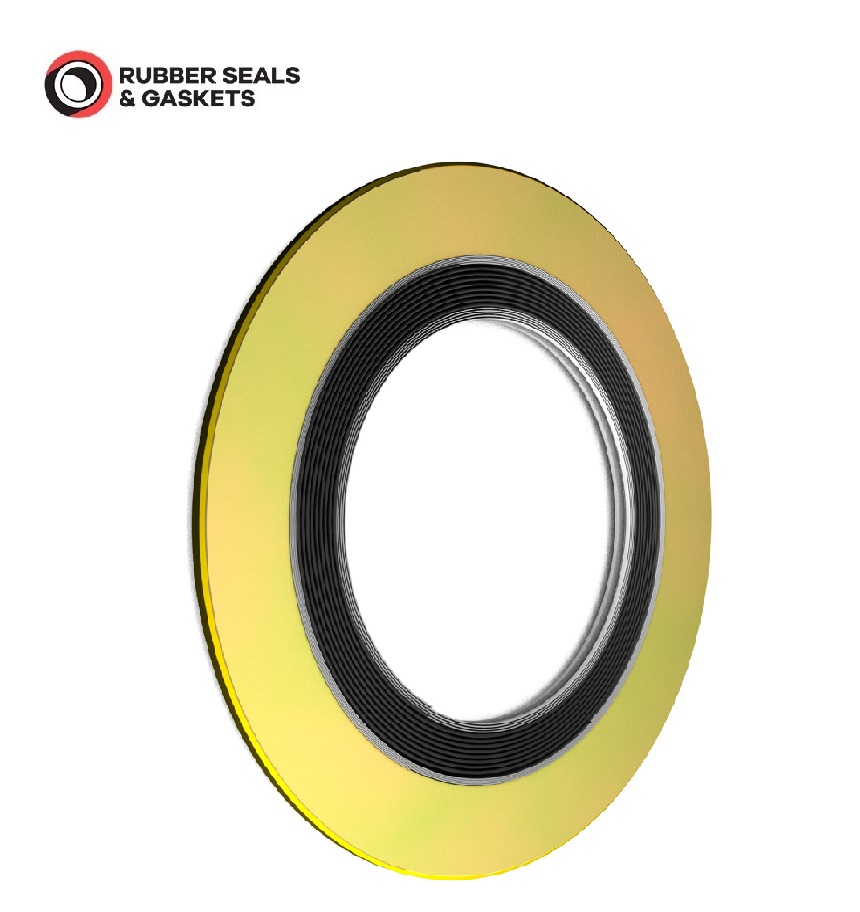

Spiral Wound Gasket Style CG

Spiral Wound Gasket Style CG

Utilizes an external ring which accurately centers gasket on flange face; provides additional radial strength to prevent gasket blowout and acts as a compression stop. A general purpose gasket suitable for use with flat face and raised face flanges. Class 900 and above an internal ring is recommended.

Dims Spiral Wound Gaskets EN 1514-2 for Flanges according to DIN EN 1092-1

| DN | ID (d1) | ID (d2) | OD (d3) | ||

| PN | PN | PN | PN | ||

| 10-320 | 10-320 | 10-40 | 64-320 | ||

| 10 | 18 | 24 | 36 | 36 | |

| 15 | 22 | 28 | 40 | 40 | |

| 20 | 27 | 33 | 47 | 47 | |

| 25 | 34 | 40 | 54 | 54 | |

| 32 | 43 | 49 | 6 | 6 | |

| 40 | 48 | 54 | 70 | 70 | |

| 50 | 57 | 66 | 84 | 84 | |

| 65 | 73 | 82 | 102 | 104 | |

| 80 | 86 | 95 | 115 | 119 | |

| 100 | 108 | 120 | 140 | 144 | |

| 125 | 134 | 146 | 168 | 172 | |

| 150 | 162 | 174 | 196 | 200 | |

| 175 | 183 | 19 | 221 | 227 | |

| 200 | 213 | 225 | 251 | 257 | |

| 250 | 267 | 279 | 307 | 31 | |

| 300 | 318 | 330 | 358 | 366 | |

| 350 | 363 | 37 | 40 | 413 | |

| 400 | 414 | 426 | 458 | 466 | |

| 450 | 460 | 478 | 526 | 551 | |

| 500 | 518 | 530 | 566 | 574 | |

| 600 | 618 | 630 | 666 | 674 | |

| 700 | 718 | 730 | 770 | 778 | |

| 800 | 818 | 830 | 874 | 882 | |

| 900 | 910 | 930 | 974 | 982 | |

| 1000 | 1010 | 1030 | 1078 | 1086 | |

| 1200 | 1210 | 1230 | 1280 | 1290 | |

| 1400 | 1420 | 1450 | 1510 | … | |

| 1600 | 1630 | 1660 | 1720 | … | |

| 1800 | 1830 | 1860 | 1920 | … | |

| 2000 | 2020 | 2050 | 2120 | … | |

| 2200 | 2230 | 2260 | 2330 | … | |

| 2400 | 2430 | 2480 | 2530 | … | |

| 2600 | 2630 | 2660 | 2730 | … | |

| 2800 | 2830 | 2860 | 2930 | … | |

| 3000 | 3030 | 3060 | 3130 | … | |

| DN | CENTRE RING OD (d4) | ||||

| PN 10 | PN 16 | PN 25 | PN 40 | PN 64 | |

| 10 | 46 | 46 | 46 | 46 | 56 |

| 15 | 51 | 51 | 51 | 51 | 61 |

| 20 | 61 | 61 | 61 | 61 | 72 |

| 25 | 71 | 71 | 71 | 71 | 82 |

| 32 | 82 | 82 | 82 | 82 | 90 |

| 40 | 92 | 92 | 92 | 92 | 103 |

| 50 | 107 | 107 | 107 | 107 | 113 |

| 65 | 127 | 127 | 127 | 127 | 137 |

| 80 | 142 | 142 | 142 | 142 | 148 |

| 100 | 162 | 162 | 168 | 168 | 174 |

| 125 | 192 | 192 | 194 | 194 | 210 |

| 150 | 217 | 217 | 224 | 224 | 247 |

| 175 | 247 | 247 | 254 | 26 | 277 |

| 200 | 272 | 272 | 284 | 290 | 309 |

| 250 | 327 | 328 | 340 | 352 | 364 |

| 300 | 377 | 383 | 400 | 417 | 424 |

| 350 | 437 | 443 | 457 | 474 | 486 |

| 400 | 488 | 495 | 514 | 546 | 543 |

| 450 | 558 | 567 | 574 | 578 | 534 |

| 500 | 593 | 617 | 624 | 628 | 657 |

| 600 | 69 | 734 | 731 | 747 | 764 |

| 700 | 810 | 804 | 833 | 852 | 879 |

| 800 | 917 | 911 | 942 | 974 | 988 |

| 900 | 1017 | 1011 | 1042 | 1084 | 1108 |

| 1000 | 1124 | 1128 | 1154 | 1194 | 1220 |

| 1200 | 1341 | 1342 | 1364 | 1398 | 1452 |

| 1400 | 1548 | 1542 | 1578 | 1618 | … |

| 1600 | 1772 | 1764 | 1798 | 1830 | … |

| 1800 | 1972 | 1964 | 2000 | … | … |

| 2000 | 2182 | 2168 | 2230 | … | … |

| 2200 | 2384 | 2376 | … | … | … |

| 2400 | 2594 | … | … | … | … |