Rod and Piston Seals: Ensuring Reliable Hydraulic and Pneumatic Systems

Rod and piston seals are essential components in hydraulic and pneumatic systems, playing a crucial role in ensuring efficient operation by preventing leaks and maintaining pressure. These seals help keep contaminants out, reduce wear and tear, and enhance the overall performance of machinery across industries like automotive, construction, and manufacturing.

In this article, we’ll explore the importance, types, materials, and applications of rod and piston seals while highlighting their benefits and maintenance tips for optimal performance.

What Are Rod and Piston Seals?

Rod Seals

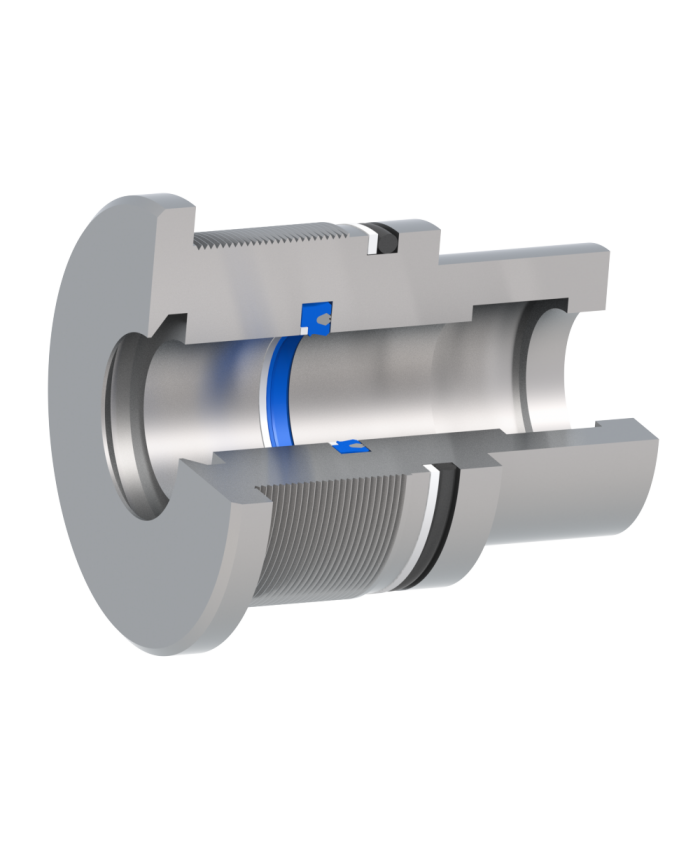

Rod seals, also known as shaft seals, are installed in the hydraulic cylinder head to prevent fluid leakage along the rod’s surface as it moves in and out of the cylinder.

Piston Seals

Piston seals, also called cylinder seals, are placed inside the cylinder to prevent fluid from bypassing the piston, ensuring proper pressure buildup and efficient motion transfer.

Both seals work together to maintain a closed hydraulic or pneumatic system, ensuring leak-proof and reliable operation.

Importance of Rod and Piston Seals

1. Leak Prevention

Rod and piston seals prevent internal and external leaks, ensuring the system operates efficiently.

2. Contaminant Exclusion

They keep dust, dirt, and other contaminants from entering the system, protecting sensitive components.

3. Pressure Maintenance

Piston seals maintain pressure within the cylinder, enabling efficient energy transfer.

4. Reduced Wear and Tear

High-quality seals minimize friction and wear on rods and pistons, extending the lifespan of the equipment.

5. Cost Efficiency

By preventing leaks and reducing downtime, these seals save on maintenance costs and enhance productivity.

Types of Rod and Piston Seals

Rod Seals

U-Cup Seals

- Designed for low-friction performance.

- Common in hydraulic systems.

V-Ring Seals

- Excellent for high-speed applications.

- Provide consistent sealing under dynamic conditions.

Buffer Seals

- Act as secondary seals to protect the primary rod seal.

- Absorb pressure spikes and enhance seal durability.

Piston Seals

Single-Acting Piston Seals

- Seal in one direction only.

- Used in simple applications requiring one-directional motion.

Double-Acting Piston Seals

- Provide sealing in both directions.

- Ideal for applications involving bidirectional motion.

Compact Piston Seals

- Combine multiple sealing functions into a single design.

- Reduce space requirements in compact systems.

Materials for Rod and Piston Seals

Selecting the right material is critical for the performance and longevity of rod and piston seals.

1. Polyurethane (PU)

- High wear resistance and durability.

- Suitable for high-pressure applications.

2. Nitrile Rubber (NBR)

- Excellent resistance to oils and hydraulic fluids.

- Common in low-temperature applications.

3. Viton (FKM)

- Superior chemical and high-temperature resistance.

- Preferred in chemical processing and aerospace industries.

4. PTFE (Polytetrafluoroethylene)

- Low friction and excellent chemical resistance.

- Ideal for high-speed and high-temperature applications.

5. EPDM (Ethylene Propylene Diene Monomer)

- Great for water-based fluids and steam applications.

- Resistant to aging and environmental factors.

Applications of Rod and Piston Seals

Rod and piston seals are used across various industries due to their adaptability and performance:

Automotive Industry

- Shock absorbers, power steering systems, and brake cylinders.

Construction Equipment

- Excavators, loaders, and hydraulic lifts.

Oil & Gas Industry

- Hydraulic actuators and pressure control systems.

Aerospace

- Flight control systems and landing gear mechanisms.

Manufacturing

- Pneumatic tools and robotic arms.

Agriculture

- Hydraulic pumps and sprayers.

Benefits of High-Quality Rod and Piston Seals

- Enhanced Equipment Lifespan: Minimizes wear and extends the life of machinery.

- Energy Efficiency: Maintains system pressure for optimal energy usage.

- Improved Safety: Prevents leaks that could lead to equipment failure or accidents.

- Cost Savings: Reduces maintenance needs and operational downtime.

Maintenance Tips for Rod and Piston Seals

Inspect Regularly

- Check for signs of wear, cracks, or leakage.

Use Compatible Fluids

- Ensure the hydraulic or pneumatic fluid is compatible with the seal material.

Clean Components

- Keep rods and pistons clean to avoid seal contamination.

Replace Worn Seals

- Replace seals promptly to prevent system failure.

Follow Installation Guidelines

- Ensure proper alignment and lubrication during installation.

Why Choose Rubber Seals and Gaskets for Rod and Piston Seals?

At Rubber Seals and Gaskets, we provide premium-quality rod and piston seals designed to meet diverse industrial needs.

What Sets Us Apart?

- High-Quality Materials: Seals made from top-grade elastomers and polymers.

- Custom Solutions: Tailored designs to fit specific system requirements.

- Expert Advice: Technical support to help you choose the right seal for your application.

- Competitive Pricing: Affordable sealing solutions without compromising quality.

Conclusion

Rod and piston seals are indispensable components in hydraulic and pneumatic systems, ensuring leak-proof operation, maintaining pressure, and extending equipment life. By choosing high-quality seals from trusted suppliers like Rubber Seals and Gaskets, you can enhance system efficiency and reduce maintenance costs.

Contact us today to explore our wide range of rod and piston seals and find the perfect solution for your industrial applications.

FAQs

Rod seals prevent hydraulic fluid from leaking out of the cylinder along the rod’s surface, ensuring efficient system operation.

Yes, they are widely used in both hydraulic and pneumatic systems.

Seals should be inspected regularly and replaced when signs of wear or leakage are detected to maintain system efficiency.

For premium sealing solutions, trust Rubber Seals and Gaskets to deliver exceptional quality and service!