Rubber Grommets: Essential Components for Industrial Sealing and Protection

Rubber grommets may be small, but their impact on industrial applications is significant. These versatile components are widely used for sealing, protection, and organizing wires, cables, and pipes across various industries. From reducing wear and tear to preventing leaks, rubber grommets ensure safety and durability in mechanical, electrical, and plumbing systems.

In this blog, we’ll explore the purpose, types, materials, applications, and benefits of rubber grommets while highlighting why they are a crucial part of modern engineering solutions.

What Are Rubber Grommets?

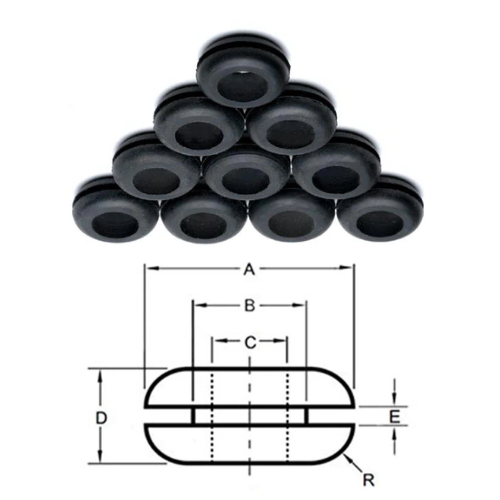

Rubber grommets are circular or oval-shaped components with a hole in the center, designed to shield and protect cables, wires, or pipes as they pass through sharp-edged holes in panels, walls, or equipment.

Their primary purpose is to:

- Provide a buffer between the edge of the hole and the inserted object.

- Prevent abrasion, vibration, or damage.

- Offer a seal to keep out dust, moisture, and debris.

Rubber grommets are widely used in industries that require reliable protection for electrical components, pipes, or delicate systems.

Importance of Rubber Grommets

Protection from Abrasion

- Prevents cables and wires from getting cut or frayed when passing through metal or other sharp surfaces.

Sealant Properties

- Ensures a tight seal, keeping out dust, water, and contaminants that can damage equipment.

Vibration Dampening

- Absorbs vibrations and minimizes noise in machinery or electrical systems.

Safety Enhancement

- Reduces the risk of electrical short circuits by preventing wire insulation damage.

Cost-Effective Solution

- An affordable way to enhance durability and efficiency in various applications.

Types of Rubber Grommets

1. Standard Grommets

- The most commonly used type for general protection and insulation.

- Ideal for electrical wires and cables.

2. Blind Grommets

- Feature a closed center to seal unused holes.

- Prevent entry of dust, water, or debris into enclosures.

3. Split Grommets

- Designed with a split for easy installation without removing existing cables.

- Used in retrofitting applications.

4. Push-In Grommets

- Easy to install with a simple push-fit design.

- Suitable for light-duty sealing and protection.

5. Custom Grommets

- Tailored designs to meet specific industrial or operational requirements.

Materials Used for Rubber Grommets

Choosing the right material ensures optimal performance and longevity:

1. Natural Rubber

- Flexible and resilient.

- Suitable for general-purpose applications.

2. EPDM (Ethylene Propylene Diene Monomer)

- Excellent weather and UV resistance.

- Ideal for outdoor applications.

3. Nitrile Rubber (NBR)

- Outstanding resistance to oils, fuels, and chemicals.

- Common in automotive and industrial applications.

4. Silicone

- Exceptional temperature resistance (-60°C to +200°C).

- Preferred in high-temperature environments and medical equipment.

5. Neoprene

- Durable and resistant to ozone and environmental degradation.

- Suitable for marine and industrial uses.

Applications of Rubber Grommets

Rubber grommets are indispensable across various industries:

1. Automotive Industry

- Used in wiring harnesses, engine compartments, and fuel systems to protect cables and hoses.

2. Electrical and Electronics

- Shield wires and cables passing through enclosures or panels.

- Maintain insulation and prevent electrical short circuits.

3. Construction

- Seal and protect pipes, conduits, and ducts in buildings.

4. Plumbing

- Prevent leaks and secure fittings in piping systems.

5. Aerospace

- Used in aircraft wiring and control systems for durability in extreme conditions.

6. Medical Equipment

- Ensure hygienic and secure sealing in medical devices.

Benefits of High-Quality Rubber Grommets

- Durability: Long-lasting protection against wear and environmental factors.

- Versatility: Adaptable to a variety of applications and environments.

- Ease of Installation: Quick and straightforward fitting without specialized tools.

- Customizability: Available in different sizes, shapes, and materials to suit specific needs.

- Safety: Enhances safety in electrical, mechanical, and plumbing systems.

How to Choose the Right Rubber Grommet

When selecting a rubber grommet, consider the following factors:

Material Compatibility

- Choose a material that withstands the operating environment (e.g., temperature, chemicals, or UV exposure).

Size and Fit

- Ensure the grommet fits snugly into the hole and around the cable or pipe.

Application Type

- Select the appropriate grommet type (e.g., split grommet for retrofits).

Operating Environment

- Consider exposure to moisture, heat, or harsh chemicals.

Why Choose Rubber Seals and Gaskets for Rubber Grommets?

At Rubber Seals and Gaskets, we pride ourselves on providing premium-quality rubber grommets designed to meet diverse industrial needs.

Our Advantages:

- High-Quality Materials: Durable and reliable grommets for long-lasting performance.

- Custom Solutions: Tailored designs to fit unique operational requirements.

- Expert Guidance: Professional support to help you choose the perfect grommet for your application.

- Competitive Pricing: Affordable without compromising quality.

If you’re looking for high-quality Ring Joint Gaskets tailored to your specific needs, explore our comprehensive range at Rubber Seals and Gaskets. We offer premium sealing solutions designed to enhance the safety and efficiency of your operations.

Conclusion

Rubber grommets are small yet powerful components that ensure safety, protection, and durability in industrial systems. Whether you need to safeguard electrical wires, seal pipes, or dampen vibrations, these versatile components are indispensable for enhancing efficiency and reliability.

For top-quality rubber grommets and exceptional service, trust Rubber Seals and Gaskets. Contact us today to explore our extensive range of sealing solutions!

FAQs

Rubber grommets protect wires, cables, and pipes from abrasion, seal against contaminants, and dampen vibrations.

Yes, grommets made from materials like EPDM and silicone are ideal for outdoor applications due to their weather resistance.

Simply press the grommet into the hole and insert the wire, cable, or pipe through the center. Split grommets are easier to install without disconnecting existing systems.

Yes, we provide custom grommet solutions tailored to your specific needs.

Explore premium rubber grommet options with Rubber Seals and Gaskets today!