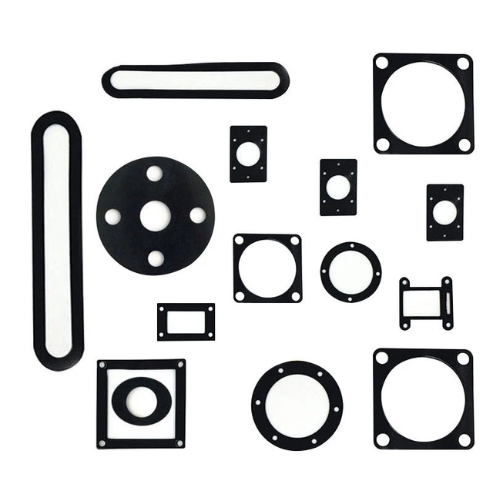

Rubber Washers: Essential Sealing Solutions for Diverse Applications

Rubber washers are one of the most versatile and indispensable components in sealing and fastening solutions across industries. Known for their ability to provide a tight seal, dampen vibrations, and resist wear and tear, rubber washers are used extensively in automotive, plumbing, construction, and various industrial applications.

In this article, we’ll explore the characteristics, benefits, applications, and types of rubber washers, along with tips on selecting the right washer for your specific needs.

What Is a Rubber Washer?

A rubber washer is a flat, ring-shaped component made from elastomeric materials like natural rubber, silicone, nitrile, EPDM, or Viton. Its primary purpose is to create a secure seal between two surfaces, preventing leaks and providing insulation against vibrations, friction, and environmental factors.

Rubber washers come in various sizes, thicknesses, and material compositions, making them suitable for a wide range of applications.

Key Benefits of Rubber Washers

1. Leak Prevention

Rubber washers form a tight seal, preventing fluid or gas leakage in plumbing, automotive, and industrial systems.

2. Vibration Dampening

Their elasticity absorbs vibrations, reducing noise and wear in mechanical systems.

3. Flexibility

Rubber washers can adapt to irregular surfaces, ensuring an effective seal in uneven or dynamic environments.

4. Chemical and Temperature Resistance

Depending on the material, rubber washers can withstand exposure to harsh chemicals, oils, and extreme temperatures.

5. Durability

Quality rubber washers are resistant to cracking, tearing, and deformation, ensuring long-lasting performance.

6. Cost-Effective

They offer a reliable and affordable sealing solution for a variety of applications.

Common Types of Rubber Washers

1. Flat Rubber Washers

- Standard design for sealing and cushioning.

- Ideal for plumbing, automotive, and general industrial use.

2. Sealing Washers

- Designed for watertight or airtight seals.

- Commonly used in water pipes, faucets, and HVAC systems.

3. Cushioning Washers

- Absorb vibrations and reduce noise.

- Suitable for electronic and mechanical equipment.

4. Insulating Washers

- Provide electrical insulation between components.

- Used in electronics and electrical applications.

5. Custom Rubber Washers

- Tailored for specific sizes, shapes, and material requirements.

- Perfect for unique industrial applications.

Materials Used for Rubber Washers

The choice of material for rubber washers depends on the specific application and environmental conditions.

1. Natural Rubber

- High elasticity and flexibility.

- Suitable for general-purpose applications.

2. EPDM (Ethylene Propylene Diene Monomer)

- Excellent resistance to UV, ozone, and water.

- Common in outdoor and plumbing applications.

3. Nitrile Rubber (Buna-N)

- Resistant to oils and fuels.

- Ideal for automotive and industrial uses.

4. Silicone Rubber

- High-temperature tolerance and non-toxic properties.

- Widely used in food-grade and medical applications.

5. Viton (FKM)

- Exceptional chemical and heat resistance.

- Perfect for demanding chemical processing environments.

Applications of Rubber Washers

Rubber washers are indispensable in numerous industries due to their versatility and reliability.

1. Plumbing

- Create watertight seals in faucets, pipes, and pumps.

2. Automotive

- Provide seals in engines, fuel systems, and braking systems.

3. Construction

- Absorb shocks and vibrations in structural elements.

4. Electronics

- Act as electrical insulators and protect components from vibrations.

5. Aerospace

- Used in high-performance sealing applications under extreme conditions.

6. HVAC Systems

- Prevent leaks in ducts, vents, and heating or cooling units.

How to Choose the Right Rubber Washer

1. Understand the Application

- Determine the environment (temperature, pressure, chemical exposure) in which the washer will be used.

2. Select the Right Material

- Match the washer material to the application’s specific requirements.

3. Consider the Size and Thickness

- Ensure the washer fits correctly to provide an effective seal.

4. Opt for Reinforced Washers

- For high-pressure applications, choose washers with added reinforcement.

Maintenance Tips for Rubber Washers

Inspect Regularly

- Check for signs of wear, cracking, or deformation.

Clean Properly

- Remove debris and contaminants that could degrade the washer.

Replace When Necessary

- Replace washers promptly to maintain system integrity.

Store Correctly

- Store in a cool, dry place away from direct sunlight to prevent premature aging.

Why Choose Rubber Seals and Gaskets for Rubber Washers?

At Rubber Seals and Gaskets, we specialize in providing premium-quality rubber washers tailored to your needs.

Key Features:

- Wide Material Selection: Choose from natural rubber, EPDM, Nitrile, and more.

- Custom Solutions: Get washers in the exact size and shape you need.

- High Durability: Products designed to withstand challenging conditions.

- Competitive Pricing: Affordable options without compromising quality.

Conclusion

Rubber washers are vital components for ensuring effective sealing, vibration dampening, and insulation in various industrial and domestic applications. With their versatility and durability, they have become the go-to solution for engineers and technicians worldwide.

For reliable and high-quality rubber washers, contact Rubber Seals and Gaskets today. Our expert team is ready to help you find the perfect washer for your application and ensure optimal performance in your systems.

FAQs

Rubber washers are used for sealing, vibration damping, and insulation in various systems, including plumbing, automotive, and electronics.

The best material depends on the application; EPDM is great for water resistance, while Nitrile is ideal for oil and fuel applications.

With proper maintenance, high-quality rubber washers can last for years, even in demanding environments.

Let Rubber Seals and Gaskets be your trusted partner for all your rubber washer needs!