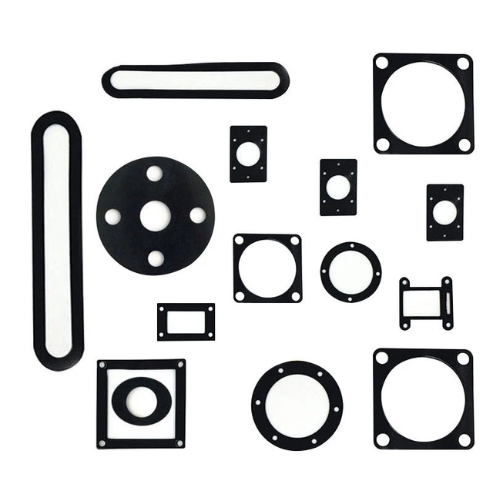

Strength Rubber Washer: A Reliable Solution for Sealing and Durability

When it comes to industrial sealing solutions, strength rubber washers are an essential component that ensures durability, flexibility, and resistance to harsh conditions. These washers play a critical role in various industries, including automotive, aerospace, plumbing, and heavy machinery, by providing a strong seal and preventing leaks.

In this blog, we will explore the benefits, applications, types, and factors to consider when choosing strength rubber washers.

What is a Strength Rubber Washer?

A strength rubber washer is a flat, circular disc made from high-quality rubber materials, designed to distribute loads, prevent leakage, and reduce vibrations. These washers are used to create a secure seal between two surfaces, ensuring that fluids, air, or gases do not escape.

They are particularly effective in applications that require high tensile strength, chemical resistance, and thermal stability.

Unlike other types of gaskets, RJGs are metallic, making them highly resistant to deformation under extreme pressure. They are often oval or octagonal in shape, depending on the specific application and flange type.

Key Benefits of Strength Rubber Washers

1. Excellent Sealing Properties

Prevents leakage of liquids and gases.

Ensures a tight and secure connection between components.

2. High Durability and Flexibility

Resistant to wear, pressure, and environmental factors.

Maintains elasticity over extended periods.

3. Chemical and Corrosion Resistance

Withstands exposure to oils, solvents, and chemicals.

Ideal for use in harsh industrial environments.

4. Shock and Vibration Absorption

Reduces noise and mechanical impact.

Enhances the longevity of machinery and equipment.

5. Temperature and Weather Resistance

Performs well under extreme hot and cold conditions.

UV and ozone-resistant for outdoor applications.

Applications of Strength Rubber Washers

1. Automotive Industry

Used in engines, fuel systems, and exhaust systems.

Provides resistance to high temperatures and mechanical stress.

2. Plumbing and Water Systems

Ensures leak-proof sealing in pipes and faucets.

Prevents water damage by maintaining a secure connection.

3. Aerospace and Aviation

Used in aircraft engines and hydraulic systems.

Offers reliability under high-pressure conditions.

4. Industrial Machinery and Equipment

Reduces vibration and shock in heavy machinery.

Extends the lifespan of industrial components.

5. Electronics and Electrical Systems

Provides insulation and protection in electrical components.

Prevents short circuits by sealing gaps.

Types of Strength Rubber Washers

1. Neoprene Rubber Washers

Resistant to oil, chemicals, and extreme temperatures.

Commonly used in HVAC, plumbing, and automotive applications.

2. EPDM Rubber Washers

Excellent resistance to UV, ozone, and weather conditions.

Ideal for outdoor and marine applications.

3. Silicone Rubber Washers

Withstands high temperatures and flexible under low temperatures.

Used in food processing, medical, and electrical industries.

4. Nitrile Rubber Washers

Superior oil and fuel resistance.

Preferred for automotive and petroleum industries.

5. Viton Rubber Washers

Exceptional chemical and heat resistance.

Suitable for high-performance sealing applications.

Factors to Consider When Choosing Strength Rubber Washers

When selecting a strength rubber washer, consider the following factors to ensure optimal performance:

1. Material Compatibility

Choose rubber material based on the application requirements.

Ensure resistance to chemicals, oils, and environmental exposure.

2. Temperature Range

Verify that the washer can withstand extreme temperatures if needed.

Silicone and Viton are ideal for high-temperature environments.

3. Pressure and Load Capacity

Determine the washer’s ability to handle mechanical stress.

High-strength rubber washers prevent deformation under heavy loads.

4. Size and Thickness

Select the correct diameter and thickness for proper sealing.

Custom sizes are available for specific applications.

5. Compliance with Industry Standards

Ensure washers meet industry regulations such as ASTM, ISO, or FDA standards.

Guarantees quality, safety, and performance.

Why Choose Rubber Seals and Gaskets for Strength Rubber Washers?

At Rubber Seals and Gaskets, we manufacture and supply premium-quality strength rubber washers for various industries. Here’s why you should choose us:

✔ High-Quality Materials – We use top-grade rubber to ensure maximum durability.

✔ Custom Solutions – We offer custom-designed washers to fit unique applications.

✔ Advanced Manufacturing Techniques – Ensures precision and superior bonding.

✔ Strict Quality Control – Our products undergo rigorous testing for reliability.

✔ Industry Expertise – Years of experience in producing top-tier sealing solutions.

Conclusion

Strength rubber washers are essential in sealing and securing various industrial applications. Their ability to withstand extreme conditions, resist chemicals, and absorb shocks makes them a valuable component in automotive, aerospace, plumbing, and heavy machinery industries.

Looking for high-performance strength rubber washers? Contact Rubber Seals and Gaskets today to get the best sealing solutions tailored to your needs!

FAQs

It provides sealing, shock absorption, and prevents leaks in various applications.

Neoprene, EPDM, silicone, nitrile, and Viton are commonly used based on industry requirements.

Yes, certain materials like silicone and Viton are designed for high-temperature environments.

Yes! We provide customized strength rubber washers based on your specifications.

Enhance your sealing performance with high-quality strength rubber washers from Rubber Seals and Gaskets! Contact us today to find the perfect solution for your industry.