The Role of Rubber Seals and Gaskets in the Electrical & Semiconductor Industry

Introduction

The electrical and semiconductor industries demand high-performance sealing solutions to ensure the safety, reliability, and longevity of sensitive electronic components. Rubber seals and gaskets play a crucial role in protecting against environmental contaminants, moisture, and electrical interference.

In this blog, we will explore the importance of rubber seals and gaskets in the electrical and semiconductor industry, their benefits, common materials used, and key applications.

Importance of Rubber Seals and Gaskets

Sealing solutions are integral to electrical and semiconductor applications due to the following reasons:

Protection Against Environmental Factors: Electrical components are vulnerable to dust, moisture, and temperature variations. Rubber seals and gaskets help create airtight and watertight seals, preventing component failure.

Electrical Insulation: Many rubber compounds used in seals and gaskets offer excellent electrical insulation, reducing the risk of short circuits and improving safety.

Chemical and Thermal Resistance: Semiconductor manufacturing involves exposure to harsh chemicals and high temperatures. Seals and gaskets made from materials like silicone and fluorocarbon (FKM) can withstand these extreme conditions.

Vibration Damping: Electrical enclosures and semiconductor equipment often experience vibrations that can loosen connections. Rubber seals help absorb these vibrations, ensuring the stability of electrical systems.

Common Materials Used in Electrical & Semiconductor Seals

Rubber seals and gaskets for electrical and semiconductor applications are made from high-performance elastomers. Some of the most commonly used materials include:

Silicone: Ideal for high-temperature applications and excellent electrical insulation.

EPDM (Ethylene Propylene Diene Monomer): Provides outstanding resistance to ozone, UV, and extreme weather conditions.

Fluorocarbon (FKM/Viton®): Offers superior chemical and heat resistance.

Neoprene: Provides good resistance to oil, chemicals, and weathering.

PTFE (Polytetrafluoroethylene): Has excellent dielectric properties and is resistant to aggressive chemicals.

Key Applications of Rubber Seals and Gaskets in the Electrical & Semiconductor Industry

1. Electrical Enclosures

Rubber gaskets are used in electrical enclosures to protect sensitive circuits and components from environmental damage, dust, and moisture ingress.

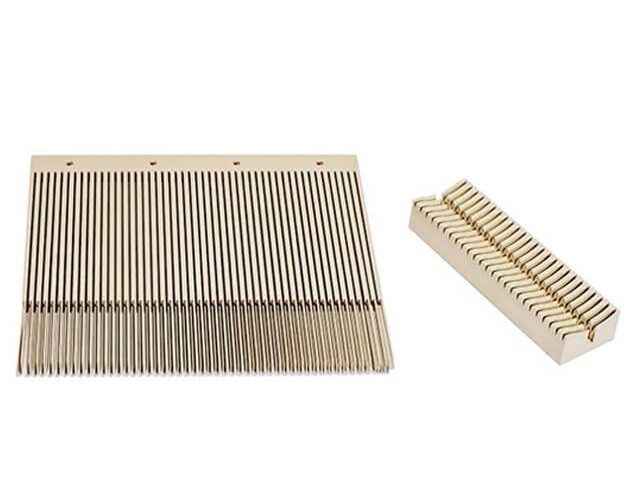

2. Semiconductor Manufacturing Equipment

Seals and gaskets are crucial in semiconductor fabrication processes, where they provide chemical and thermal resistance to withstand harsh conditions.

3. High-Voltage Insulation

Many electrical applications require insulating materials that prevent short circuits. Rubber gaskets with high dielectric properties help maintain system integrity.

4. Connectors and Cable Seals

Cable glands and connectors require reliable sealing to prevent water, dust, and other contaminants from affecting electrical connections.

5. Cleanroom Environments

Semiconductor manufacturing takes place in cleanrooms where contamination control is critical. Rubber gaskets and seals are used in cleanroom doors, ventilation systems, and equipment enclosures.

Advantages of Using Rubber Seals and Gaskets in the Electrical & Semiconductor Industry

Enhances safety by preventing electrical hazards

Increases the lifespan of electronic components

Reduces maintenance costs by preventing contamination-related failures

Ensures compliance with industry standards and regulations

Improves overall performance and reliability of electrical and semiconductor equipment

Conclusion

Rubber seals and gaskets are indispensable in the electrical and semiconductor industry, ensuring the protection and longevity of critical components. Selecting the right sealing solution enhances efficiency, reduces risks, and improves overall equipment performance.

FAQs

Silicone and PTFE are excellent choices due to their high dielectric strength and resistance to high temperatures.

Yes, specialized rubber gaskets with low outgassing properties are used in cleanroom environments to maintain air purity.

Yes, materials like FKM (Viton®) and PTFE provide excellent chemical resistance for semiconductor applications.

Rubber gaskets create a tight seal that prevents water and humidity from entering enclosures, reducing the risk of short circuits and corrosion.

Looking for high-quality rubber seals and gaskets for your electrical or semiconductor applications? Contact us today to find the best sealing solutions tailored to your needs!