Peek Products

-

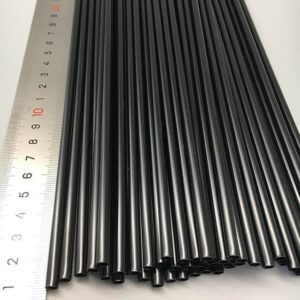

PEEK Insulated Outer Tube for Laparoscopic Instruments

- PEEK Insulated Outer Tube for Laparoscopic Instruments Material: PEEK Black Available Diamater: Φ5mm, Φ10mm and Customized L 330mm, 450mm or Customized Features: - Excellent insulation properties The insulation strength of 5KV can be reached by 0.2mm on one side - Robust material maintains integrity during sterilization cycles

-

PEEK insulating tube for laparoscopy forceps

- PEEK insulating tube for laparoscopy forceps Material: PEEK Available Diamater: Φ5mm, Φ10mm and Customized Features: - Excellent insulation properties The insulation strength of 5KV can be reached by 0.2mm on one side - Robust material maintains integrity during sterilization cycles

-

PEEK Manifold

- PEEK Manifold Polyetheretherketone Natural (beige), grey, Black Properties Superior wear resistance and dimensional stability to 480°F continuous use Excellent resistance to chemicals, steam and hydrolysis Very low moisture absorption Very high thermal stability (V-O UL 94 rating) Superb flexural and torsional strength Abrasion resistant Good dielectric properties Good resistance to radiation Self-extinguishing FDA, USDA, 3-A Dairy compliant

-

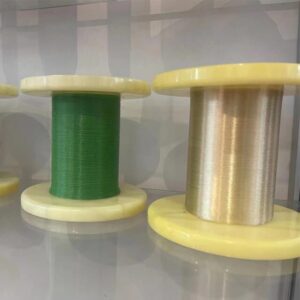

PEEK Monofilament PEEK Fiber

- PEEK Monofilament, PEEK Fiber Available Diameter: 0.06; 0.07; 0.10; 0.15; 0.20; 0.28; 0.30; 0.35; 0.38; 0.40; 0.45; 0.50; 0.55; 0.60; 0.70; 0.80; 0.90; 1.00mm; Or Customized. Color: Natural & Black Other colors can be customized

-

PEEK Mounting Blocks

- PEEK Mounting Blocks Polyetheretherketone Natural (beige), grey, Black Properties Superior wear resistance and dimensional stability to 480°F continuous use Excellent resistance to chemicals, steam and hydrolysis Very low moisture absorption Very high thermal stability (V-O UL 94 rating) Superb flexural and torsional strength Abrasion resistant Good dielectric properties Good resistance to radiation Self-extinguishing FDA, USDA, 3-A Dairy compliant

-

PEEK Nozzle inserts for Piezoelectric Jet Dispensing Valve

- PEEK nozzle inserts for Piezoelectric Jet Dispensing Valve Advantages: • Suit for reactive adhesives like anaerobics • Fast and easy serviceability and maintenance • Easy cleaning • High temperature resistance

-

PEEK Pan Head Phillips Screw

- PEEK Pan Head Phillips Screw

-

PEEK Pan Head Slotted Screw

- PEEK Pan Head Slotted Screw

-

PEEK Plating Fixture

- Polyetheretherketone - Natural (beige), black Properties Superior wear resistance and dimensional stability to 260℃ continuous use Excellent resistance to chemicals, steam and hydrolysis Very low moisture absorption Very high thermal stability (V-O UL 94 rating) Superb flexural and torsional strength Abrasion resistant Good dielectric properties Good resistance to radiation Self-extinguishing

-

PEEK Radial Ball Bearings

- PEEK Radial Ball Bearings Polyetheretherketone Natural (beige), Black PEEK radial ball bearings operate in much higher temperatures than other plastic ball bearings. They also have good chemical resistance and excellent corrosion resistance. The purpose of a PEEK ceramic hybrid radial bearing is to withstand high temperatures and corrosion, reduce rotational friction and support loads. Benefits & Advantages of PEEK Radial Ball…

-

PEEK Sealing

- PEEK is a special engineering plastic with excellent comprehensive properties. In the application of sealing rings, especially high pressure sealing, due to its excellent compression resistance, fatigue resistance, corrosion resistance, temperature resistance, it can meet the sealing requirements of different occasions. PolyEtherEtherKetone (PEEK) Maintains wear resistance and mechanical strength up to 260℃ continuous use. PEEK is the performance material of…

-

PEEK Sleeve

- Polyetheretherketone - Natural (beige), Black Properties Superior wear resistance and dimensional stability to 260℃ continuous use Excellent resistance to chemicals, steam and hydrolysis Very low moisture absorption Very high thermal stability (V-O UL 94 rating) Superb flexural and torsional strength Abrasion resistant Good dielectric properties Good resistance to radiation Self-extinguishing

-

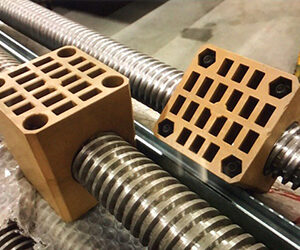

PEEK Spindle Nut for Monforts Stenter

- PEEK Spindle Nut for Monforts Stenter Material: PEEK Spec.: Tr 44 x 7, Tr 45 x 8

-

PEEK Spur Gear

- Polyetheretherketone - Natural (beige), Black Properties Superior wear resistance and dimensional stability to 260℃ continuous use Excellent resistance to chemicals, steam and hydrolysis Very low moisture absorption Very high thermal stability (V-O UL 94 rating) Superb flexural and torsional strength Abrasion resistant Good dielectric properties Good resistance to radiation Self-extinguishing

-

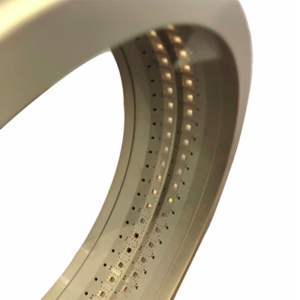

PEEK VACUUM PAD

- • PEEK vacuum pad for gentle and mark-free gripping and depositing of smooth workpieces • Application with crystalline solar cells, thin-film modules and wafers / substrates in the semiconductor industry • Handling of glass such as display glass, thin glass or coated glass without leaving a chemical fingerprint by elastomers

-

PEEK Valve Seat

- Properties Superior wear resistance and dimensional stability to 260℃ continuous use Excellent resistance to chemicals, steam and hydrolysis Very low moisture absorption Very high thermal stability (V-O UL 94 rating) Superb flexural and torsional strength Abrasion resistant Good dielectric properties Good resistance to radiation Self-extinguishing

-

Polyimide Components

- Polyimide (PI) Polyimide is a non melting high temperature polymer. Strength, dimensional stability, and creep resistance remain high even at temperatures above 260°C. Low wear rates combined with the ability to work under unlubricated conditions and high pV-rates makes it the ideal material for challenging friction and wear applications, extending lifetime and reducing maintenance costs. Its high purity and low…

-

POLYIMIDE COMPONENTS FOR SEMICONDUCTOR AND LCD INDUSTRY

- Special properties of Polyimide (PI) Long-term thermal stability 300 °C (short-term up to 400 °C) Good cryogenic properties down to -270 °C High strength, modulus and stiffness also at high temperatures over 260 °C Excellent wear resistance under high surface pressure and high sliding speeds Excellent thermal and electrical insulation Minimal thermal conductivity High purity, low outgassing in vacuum conditions…

-

POLYIMIDE GLASS HOLDER FOR LCD GLASS PANEL

- Polyimide glass holder is used for hold the LCD glass panel in glass heating progress. It has excellent properties of high temperature resistance, thermal insulation, low gas release, creep resistance. Material: Polyimide (PI) Features: High temprature resistance Wear resistance in the non-lubricant condition Free of particle generation Click Here for Material Datasheet →

-

POLYIMIDE LIFT PIN FOR LCD GLASS

- Polyimide Lift pin is used for supporting and lifting the LCD glass panel at LCD manufacturing progress. Polyimide has excellent properties of no partical release, low out gassing and stable machenical strength at high temperature. Special properties of Polyimide (PI) Long-term thermal stability 300 °C (short-term up to 400 °C) Good cryogenic properties down to -270 °C High strength, modulus…

-

POLYIMIDE ROLLER FOR LCD & CRT CONVEYOR SYSTEM

- It is a roller for LCD & CRT conveyor system in drying or wet process. Material: Polyimide (PI) Features: High temperature resistance Wear resistance in the non-lubricant condition Free of particle generation Click Here for Material Datasheet →

-

Polyimide take-out insert for Hot Glass Handling

- Polyimide take-out insert for Hot Glass Handling A range of high-performance materials for hot glass handling in applications such as tableware, glass containers, cosmetic and perfume bottles, and medical glass. With a composite structure that offers good mechanical strength and superior resistance to abrasion, and a formulation that provides an excellent stability at high temperatures, Tactylit is a unique material that…

-

POLYIMIDE(PI) HEX HEAD SCREWS

- Special properties of Polyimide (PI) Long-term thermal stability 300 °C (short-term up to 400 °C) Good cryogenic properties down to -270 °C High strength, modulus and stiffness also at high temperatures over 260 °C Excellent wear resistance under high surface pressure and high sliding speeds Excellent thermal and electrical insulation Minimal thermal conductivity High purity, low outgassing in vacuum conditions…

-

Polyimide(PI) Socket Head Cap Screw

- Special properties of Polyimide (PI) Long-term thermal stability 300 °C (short-term up to 400 °C) Good cryogenic properties down to -270 °C High strength, modulus and stiffness also at high temperatures over 260 °C Excellent wear resistance under high surface pressure and high sliding speeds Excellent thermal and electrical insulation Minimal thermal conductivity High purity, low outgassing in vacuum conditions…

End of Products

No more pages to load