PTFE Gaskets: A Comprehensive Guide for Sealing Excellence

In industrial sealing applications, PTFE (Polytetrafluoroethylene) gaskets stand out as one of the most versatile and reliable solutions. Known for their exceptional chemical resistance, durability, and ability to withstand extreme temperatures, PTFE gaskets are used in various industries to ensure leak-proof connections.

In this blog, we will explore what PTFE gaskets are, their key benefits, types, applications, and why they are an essential choice for sealing solutions in industrial settings.

What Are PTFE Gaskets?

PTFE gaskets are sealing components made from Polytetrafluoroethylene, a synthetic fluoropolymer with unique properties. This material, commonly recognized by the brand name Teflon®, is known for its non-stick characteristics, low friction, and high resistance to chemicals and temperature extremes.

PTFE gaskets are widely used in systems where harsh chemicals, high temperatures, or pressures make other gasket materials unsuitable.

Key Benefits of PTFE Gaskets

1. Chemical Resistance

PTFE is highly resistant to a broad range of chemicals, including acids, bases, and solvents, making it ideal for corrosive environments.

2. Wide Temperature Range

These gaskets perform exceptionally well in extreme temperatures, from -200°C to 260°C, maintaining their integrity without degradation.

3. Low Friction

PTFE’s low coefficient of friction minimizes wear and tear, enhancing the lifespan of both the gasket and the mating surfaces.

4. Non-Toxic and Non-Contaminating

PTFE gaskets are safe for use in industries like pharmaceuticals and food processing where contamination must be avoided.

5. Non-Adhesive Surface

The non-stick property of PTFE ensures easy removal and replacement, reducing downtime during maintenance.

6. Electrical Insulation

PTFE is an excellent electrical insulator, making it suitable for sealing applications in electronics.

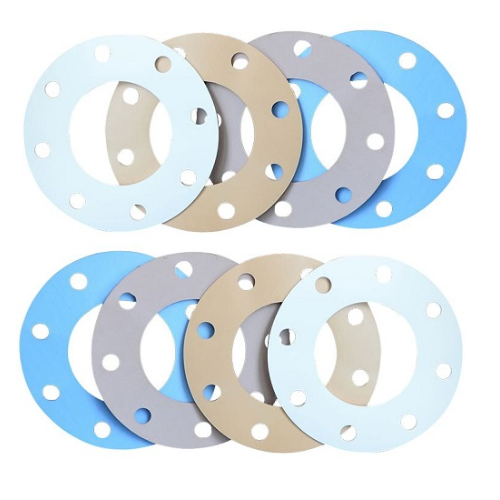

Types of PTFE Gaskets

PTFE gaskets come in various forms to suit different applications. The common types include:

1. Pure PTFE Gaskets

• Made entirely from virgin PTFE.

• Best suited for applications requiring high purity, such as food, pharmaceuticals, and electronics.

2. Expanded PTFE Gaskets

• Flexible and compressible, these gaskets provide excellent sealing even on irregular or damaged surfaces.

3. Glass-Filled PTFE Gaskets

• Enhanced strength and rigidity by incorporating glass fibers.

• Ideal for high-pressure environments.

4. Graphite-Filled PTFE Gaskets

• Improved thermal conductivity and reduced creep.

• Suitable for high-temperature applications.

5. Modified PTFE Gaskets

• Enhanced mechanical properties to address issues like cold flow and deformation.

Applications of PTFE Gaskets

PTFE gaskets are utilized across numerous industries due to their superior performance in challenging environments.

1. Chemical Processing

• Used in pipelines, valves, and flanges where aggressive chemicals are handled.

2. Oil and Gas

• Provide reliable sealing in systems exposed to hydrocarbons and extreme pressures.

3. Food and Beverage

• Ensure hygienic sealing in processing equipment, as PTFE is FDA-approved.

4. Pharmaceuticals

• Used in sterile environments due to their non-reactive and non-toxic properties.

5. Electronics

• Act as insulators in electrical systems and protect against leaks.

6. Power Generation

• Withstand high temperatures and pressures in turbines and boilers.

7. Water Treatment

• Used in systems dealing with corrosive liquids or high-pressure water flow.

PTFE Gaskets vs. Other Gasket Materials

Feature PTFE Gaskets Rubber Gaskets Metal Gaskets

Temperature Range -200°C to 260°C -30°C to 150°C Up to 600°C

Chemical Resistance Excellent Moderate Good

Flexibility High Very High Low

Durability High Moderate High

Cost Moderate Low High

Why PTFE Gaskets Are Essential for Rubber Seals and Gaskets

PTFE gaskets complement traditional rubber seals and gaskets by addressing limitations in extreme operating conditions. While rubber gaskets are ideal for flexibility and general-purpose sealing, PTFE gaskets excel in environments requiring chemical resistance, temperature stability, and low friction.

How to Choose the Right PTFE Gasket

1. Understand Operating Conditions

• Assess the temperature, pressure, and type of fluid involved.

2. Select the Right Type

• Choose from pure, filled, or modified PTFE based on your application’s needs.

3. Consider Industry Standards

• Ensure compliance with relevant standards, such as FDA for food-grade applications or ASTM for industrial use.

4. Consult Experts

• Work with a trusted supplier like Rubber Seals and Gaskets to find the perfect gasket for your system.

Maintenance Tips for PTFE Gaskets

1. Regular Inspection

o Check for signs of wear or deformation to ensure optimal performance.

2. Proper Installation

o Follow manufacturer guidelines to prevent over-compression or misalignment.

3. Timely Replacement

o Replace gaskets as needed to avoid leaks and system failures.

4. Use Compatible Materials

o Ensure the gasket material is compatible with the fluids and operating conditions.

Why Choose Rubber Seals and Gaskets for PTFE Solutions?

At Rubber Seals and Gaskets, we provide premium-quality PTFE gaskets tailored to meet the demands of various industries. Our products are known for:

- Exceptional Quality: Manufactured to precise standards for reliable performance.

- Wide Range of Options: From pure to filled PTFE, we have solutions for every application.

- Custom Solutions: Gaskets designed to fit your unique requirements.

- Expert Support: Our team offers guidance in selecting and maintaining the best gaskets for your needs.

Conclusion

PTFE gaskets are indispensable in modern industries, offering unmatched chemical resistance, temperature stability, and durability. Whether you’re in the chemical, pharmaceutical, or food processing sector, PTFE gaskets ensure leak-proof operations and prolonged system life.

At Rubber Seals and Gaskets, we are committed to delivering high-quality PTFE gaskets and comprehensive sealing solutions. Contact us today to explore our range and enhance your system’s efficiency and reliability.

FAQs

PTFE gaskets are used for sealing applications that require high chemical resistance and temperature stability.

Yes, PTFE is FDA-approved and safe for use in food and beverage processing.

With proper installation and maintenance, PTFE gaskets can last several years, even in harsh conditions.

Yes, especially when reinforced with materials like graphite or glass fibers.

Optimize your sealing solutions with the reliable and durable PTFE gaskets from Rubber Seals and Gaskets!